Leave Your Message

Choosing the right Pilot Operated Check Valve (POCV) is crucial for optimizing hydraulic systems. According to a recent industry report, the demand for POCVs is expected to grow by over 5% annually. This growth is driven by increased automation in manufacturing and energy sectors. The right valve ensures efficiency and safety, reducing operational costs.

Many factors influence this choice. Flow rate, pressure, and fluid type are key considerations. Misselecting a POCV can lead to system failures. In fact, nearly 30% of valve failures are due to incorrect specifications. This emphasizes the need for careful evaluation before purchasing. It is essential to understand your specific requirements.

Users often overlook maintenance needs, which can lead to performance issues. A well-maintained POCV can last many years, but neglect may cause leaks or system shutdowns. Recognizing the importance of accurate selection and upkeep is vital for achieving maximum reliability in hydraulic operations.

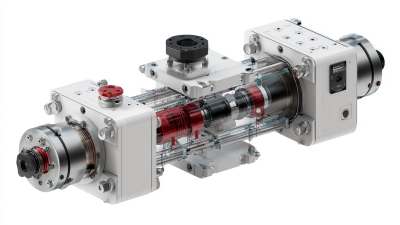

Pilot operated check valves play a crucial role in fluid systems. They allow fluid to flow in one direction while preventing backflow. This functionality is vital for maintaining system integrity. According to a recent industry report, 65% of fluid system failures are linked to backflow issues. Choosing the right valve can help mitigate these problems.

Understanding how pilot operated check valves work is essential. They are actuated by a pilot signal, allowing for greater control. When the upstream pressure exceeds the pilot pressure, the valve opens. However, if the pressure drops, the valve closes automatically. This self-regulating feature is beneficial. It requires less manual intervention, reducing the risk of errors.

Choosing the right valve must consider various factors. For instance, the flow rate, pressure, and media type matter significantly. An unsuitable valve can lead to operational inefficiencies. A study from the Fluid Control Association highlighted that 30% of installations fail to meet the specific needs of the system. It indicates a gap between specification and implementation. Careful evaluation can enhance system reliability and performance.

| Parameter | Description | Value Range | Recommended Applications |

|---|---|---|---|

| Flow Rate | The maximum capacity of fluid that can pass through the valve | 0.5 - 100 GPM | Hydraulic systems, industrial applications |

| Pressure Rating | Maximum operating pressure of the valve | 50 - 3000 PSI | High pressure hydraulic applications |

| Temperature Range | Operating temperature limits for the valve | -20°F to 250°F | Chemical processing, oil & gas industries |

| Material | Type of material used for valve construction | Aluminum, Stainless Steel, Brass | Corrosive environments, high-strength requirements |

| Mounting Configuration | The method of installation for the valve in the system | Inline, Flanged, Threaded | Versatile installations in various systems |

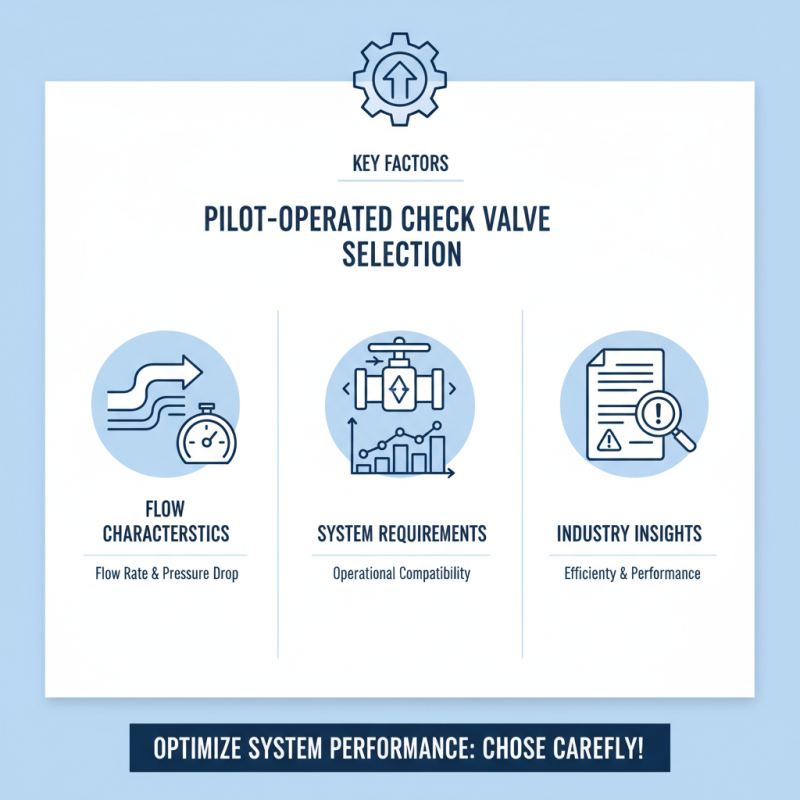

When selecting the right pilot operated check valve, several key factors require careful consideration. The flow characteristics are crucial. Different applications may demand specific flow rates and pressure drops. According to industry reports, improper flow rates can lead to valve inefficiency. Assess the system's operational requirements thoroughly to ensure compatibility.

Size is another vital factor. A valve too large or too small will affect performance. The wrong size can cause chatter or leakage, which leads to failures. It's important to match the valve size with the pipe diameter accurately. Review the specifications of your system to determine the appropriate size.

**Tip:** Always consider the fluid type in the system. Some fluids are abrasive, while others are corrosive. Select materials that can withstand these conditions.

Lastly, consider the environment where the valve will operate. Temperature and pressure extremes can degrade valve materials over time. Poor selections may lead to premature failure. Regular maintenance checks are necessary to evaluate valve conditions and prevent costly downtimes.

**Tip:** Perform regular monitoring based on the valve's operating environment. This could minimize unexpected failures.

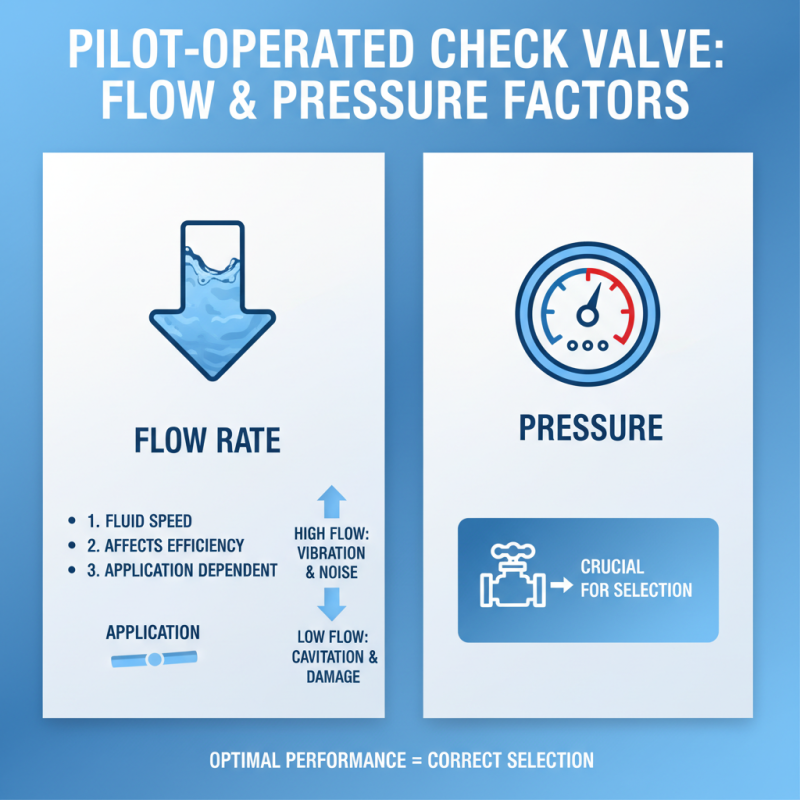

The flow rate and pressure are crucial factors when selecting a pilot operated check valve. Flow rate determines how fast the fluid moves through the system. Different applications require different flow rates, affecting the valve’s efficiency. If the flow rate is too high, it may lead to vibration and noise. Conversely, a low flow rate can cause cavitation, damaging the valve over time.

Pressure plays a vital role too. High pressure increases the risk of leaks. This demands a valve designed to handle such conditions. A valve exposed to unexpected pressure variations may fail. Monitoring these fluctuations is essential for ensuring optimal performance.

Tips: Always consider the environment where the valve will be installed. Temperature and fluid type also impact valve choices. Calculate your system’s specific needs to avoid costly mistakes. Testing prototype valves before full implementation can save time and resources. Reflect on how variations in your system could lead to an unexpected failure. Adjust accordingly to enhance reliability.

When selecting pilot operated check valves, material selection plays a crucial role in their durability. The right materials can withstand high pressures and aggressive fluids. Common materials include stainless steel, brass, and plastic. Each has its own strengths and weaknesses. For example, stainless steel resists corrosion but can be more costly.

Plastic valves are lightweight and resistant to chemicals but may not handle temperature extremes. Brass offers good corrosion resistance and is often more affordable. However, it's essential to consider the specific application when choosing materials. A flimsy choice could lead to premature failure.

Also, regularly assessing the condition of the check valve is vital. Even the best materials can degrade over time. Look for signs of wear or leakage. Choosing the wrong material can lead to significant operational problems later. Being mindful of both the application and potential materials will lead to better long-term performance.

Pilot operated check valves are vital in various industries. These valves ensure fluid flows in one direction while preventing backflow. They're commonly found in hydraulic systems, construction equipment, and manufacturing processes. Each application has specific requirements, making it essential to choose the right valve.

In construction, these valves control the movement of heavy machinery. They enhance safety by preventing unintended motion. In manufacturing, they maintain consistent pressure in production lines. It’s crucial to consider the fluid type and temperature. Not all valves handle every condition. Some may fail under extreme pressure or temperature variations.

Standards like ISO and ANSI guide valve selection. Compliance with these standards ensures quality and reliability. However, not all valves meet every industry standard. Users must research and assess their specific needs. Neglecting this can lead to inefficiencies or equipment damage. Always review specifications closely to avoid costly mistakes.