Leave Your Message

Choosing the right Solenoid Directional Control Valves can be challenging. These valves play a crucial role in fluid power systems. According to industry reports, the global market for solenoid valves is expected to reach $8.88 billion by 2025. This growth reflects increasing automation in various sectors.

Selecting a valve must consider multiple factors. These include fluid type, pressure, and flow rate. Studies show that operational efficiency improves with the right selection. However, many users overlook specific requirements. Avoiding such mistakes is essential for optimal performance. The right valve can enhance system reliability and reduce maintenance costs.

Understanding your application’s needs is vital. It often requires deep analysis and careful planning. Some users may find themselves overwhelmed by choices. It’s important to take time to evaluate options thoroughly. Making hasty decisions can lead to inefficiencies. Learning from past selections can help refine future choices for solenoid directional control valves.

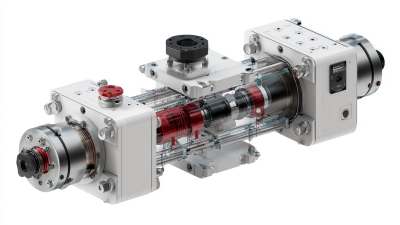

Solenoid directional control valves are essential components in hydraulic and pneumatic systems. They control the flow of fluids and direct their path. This simple mechanism can operate complex machinery. These valves use electromagnetic solenoids to shift positions. When energized, they allow fluid to flow in a desired direction.

Understanding how these valves function is crucial. Incorrectly chosen valves can lead to inefficiencies. They might not open or close properly, leading to leaks or total failures. Pay close attention to the valve’s specifications. The type and size of the valve affect performance. Matching the valve to your system requirements is key.

Pressure ratings and flow rates are important details. Operating at the correct limits ensures durability. Oversized valves may waste energy; undersized ones can restrict flow. Reflecting on these factors can save time and resources. Make decisions based on both technical requirements and practical applications. Recognizing the complexity of needs will lead to better outcomes.

| Valve Type | Functionality | Common Applications | Operating Pressure (bar) | Coil Voltage (V) |

|---|---|---|---|---|

| 2/2 Way Valve | Single control of flow, on/off | Pressurized fluid control | 10 - 50 | 24, 230 |

| 3/2 Way Valve | Switching between two output lines | Pneumatic cylinder control | 5 - 30 | 24, 120 |

| 4/2 Way Valve | Directional control for double-acting cylinders | Robotic arms, automated machinery | 8 - 40 | 24, 230 |

| 5/2 Way Valve | Control flow to double-acting cylinders | Heavy machinery, construction equipment | 10 - 40 | 24, 120 |

Solenoid directional control valves are essential in various applications. They control the flow of fluids in hydraulic and pneumatic systems. Understanding your specific needs helps to determine which valve to choose.

Key applications include machinery automation and automotive systems. In manufacturing, these valves regulate hydraulic actuators to achieve precise movements. Bus systems in cars or trucks often rely on these valves for efficient operation. However, not all applications require the same valve specification. It’s important to assess factors such as pressure, flow rate, and port configuration.

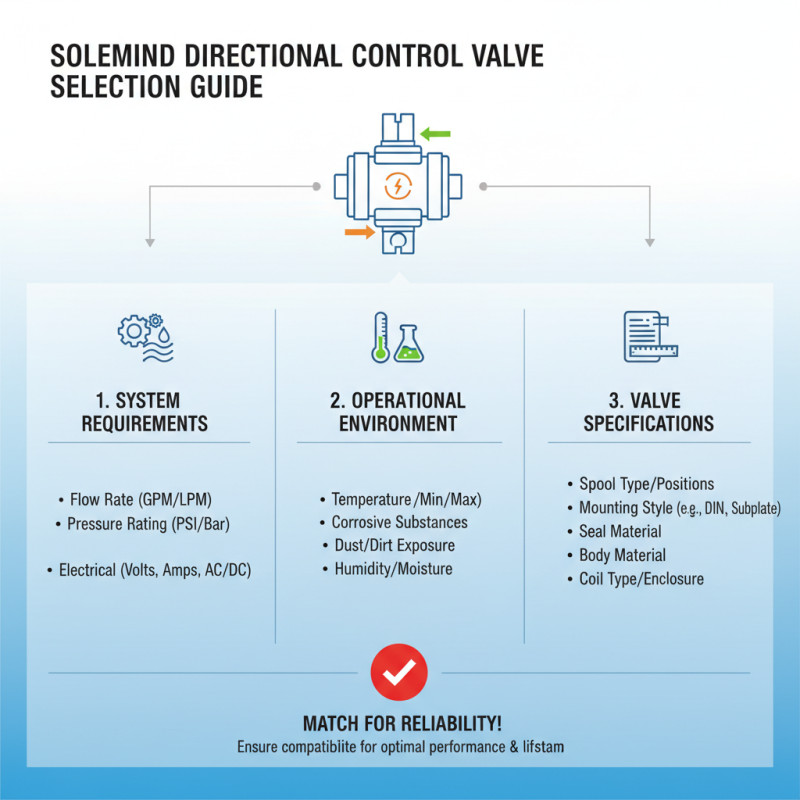

Consider the environment where the valve operates. Conditions like temperature and humidity can impact performance. For instance, some settings might expose valves to corrosive substances. In these cases, materials and protective features become a priority. Reflecting on your application’s demands will lead to better choices and enhanced system efficiency.

When selecting solenoid directional control valves, you have to consider several critical factors. The valve's specifications need to match your system requirements. This includes flow rate, pressure rating, and electrical characteristics. Not every valve will perform well under specific conditions. It's essential to understand the operational environment. Are you dealing with high temperatures? Or perhaps corrosive substances? These elements can drastically affect valve performance.

Another factor is the valve's response time. Some applications require swift action while others can tolerate delays. A valve that is too slow for a critical application may cause significant issues. Additionally, ensure the coil voltage matches your power supply. Misalignments here lead to malfunction. There is also a need to think about the installation space. Some systems are tight, making size a vital concern.

Don't overlook maintenance needs. Some valves require regular checks, while others are more robust and easier to maintain. Think about the long-term implications of your choice. It’s easy to focus solely on immediate needs. However, considering lifecycle costs is crucial. A cheap valve may become expensive when frequent replacements are necessary.

Choosing the right solenoid directional control valve can be challenging.

Evaluating valve specifications is crucial. Start by considering the flow rate required for your system.

Look at the pressure ratings too. These factors directly impact performance. Compatibility with existing equipment is often overlooked.

Misalignment can lead to inefficiencies.

When assessing compatibility, consider the size and connection type of your existing system.

Different systems may have unique requirements. Pay attention to the operating voltage as well.

It’s easy to forget that not all solenoids work on the same voltage. This can result in malfunctions and increased repair costs.

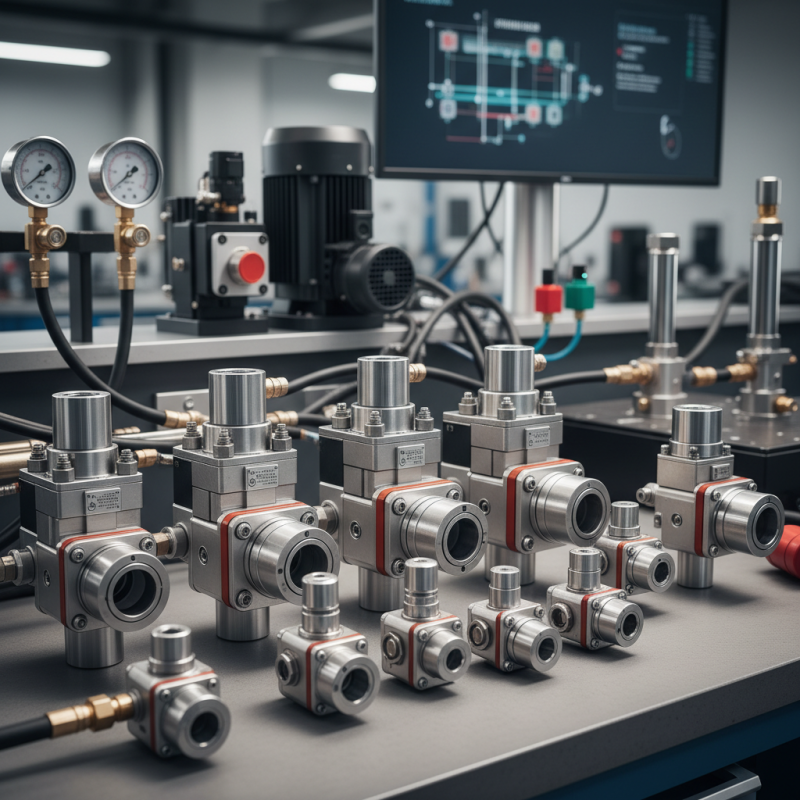

Test the selected valves in a controlled environment before full implementation.

Don't skip this step. You could encounter unexpected issues. If the valves don't integrate well, it may lead to system downtime.

Regular maintenance checks will help catch potential problems early. Sometimes, what seems to work perfectly on paper doesn’t translate in practice.

Always be ready to reflect on and adjust your choices.

Solenoid directional control valves are crucial in many hydraulic systems. Regular maintenance is key to ensure their longevity. Dirt and debris can build up in the valve. This buildup can lead to sluggish performance or even complete failure. It's essential to inspect the valves regularly. Cleaning them with a suitable solvent can help maintain optimal performance.

Troubleshooting these valves can be challenging. If you notice inconsistent operation, check the power supply first. Faulty connections can cause the solenoid to malfunction. Listening for unusual sounds during operation can also provide clues. Sometimes, the solutions are simple, like tightening screws or fixing leaks. However, persistent issues might indicate a deeper problem that requires professional attention.

Don't overlook the importance of documentation. Keeping a log of maintenance and issues can help spot patterns. This can be helpful for future troubleshooting. Remember, not all problems have immediate solutions. It's a process of trial and error. Reflect on your maintenance routine and adjust it as necessary. Effective care of solenoid directional control valves can save time and money in the long run.