Leave Your Message

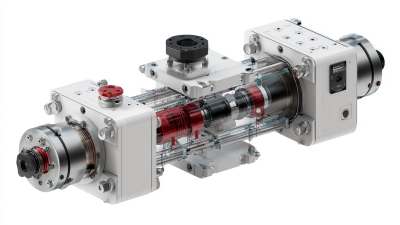

In the world of hydraulic systems, the importance of Hydraulic Threaded Cartridge Valves cannot be overstated. These valves play a crucial role in controlling fluid flow, ensuring optimal performance for various applications. According to John Smith, a leading expert in hydraulic technology, “The right cartridge valve can make or break a system's efficiency.” His insight highlights the significance of selecting the best products available.

When navigating the vast market of Hydraulic Threaded Cartridge Valves, choices can feel overwhelming. Quality and design vary significantly. Many options promise durability, yet not all deliver on performance. It’s essential to consider the specific needs of your application. Each valve must be evaluated on its unique features and capabilities, not just brands.

Finding the best valves requires careful reflection. A system is only as strong as its weakest link. Common mistakes include prioritizing cost over quality or neglecting compatibility with existing equipment. Ultimately, investing time in research will pay off by enhancing overall system reliability and efficiency.

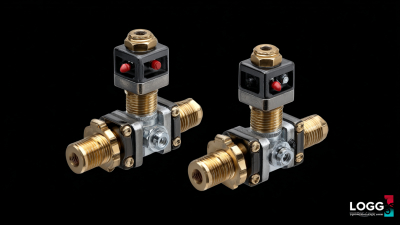

Choosing the right hydraulic threaded cartridge valves is crucial for any hydraulic system. The first factor to consider is the valve’s pressure rating. It must handle the maximum pressure within your application. If it's too low, it may fail. High pressure can lead to leaks. That’s a risk you don’t want to take.

Another important aspect is the flow rate. Different applications require different flow rates. A mismatch can hinder performance and efficiency. It's essential to understand your system needs. Additionally, consider the valve's size and port configuration. They must fit correctly into your setup. If not, you may face difficulties during installation.

Lastly, material selection matters. Valves made from durable materials resist wear and prolong life. Corrosion resistance is also vital, especially in harsh environments. However, not all options are perfect. Sometimes, cheaper materials seem appealing, but they may cost more in the long run. A thoughtful evaluation of all these factors is necessary. It can help you avoid costly mistakes later on.

| Valve Type | Flow Rate (L/min) | Pressure Rating (Bar) | Body Material | Temperature Range (°C) |

|---|---|---|---|---|

| Directional Control Valve | 120 | 350 | Steel | -20 to 80 |

| Pressure Relief Valve | 100 | 400 | Aluminum | -30 to 90 |

| Flow Control Valve | 150 | 300 | Cast Iron | -10 to 70 |

| Check Valve | 80 | 250 | Brass | -20 to 60 |

| Cartridge Valve | 90 | 320 | Stainless Steel | -40 to 100 |

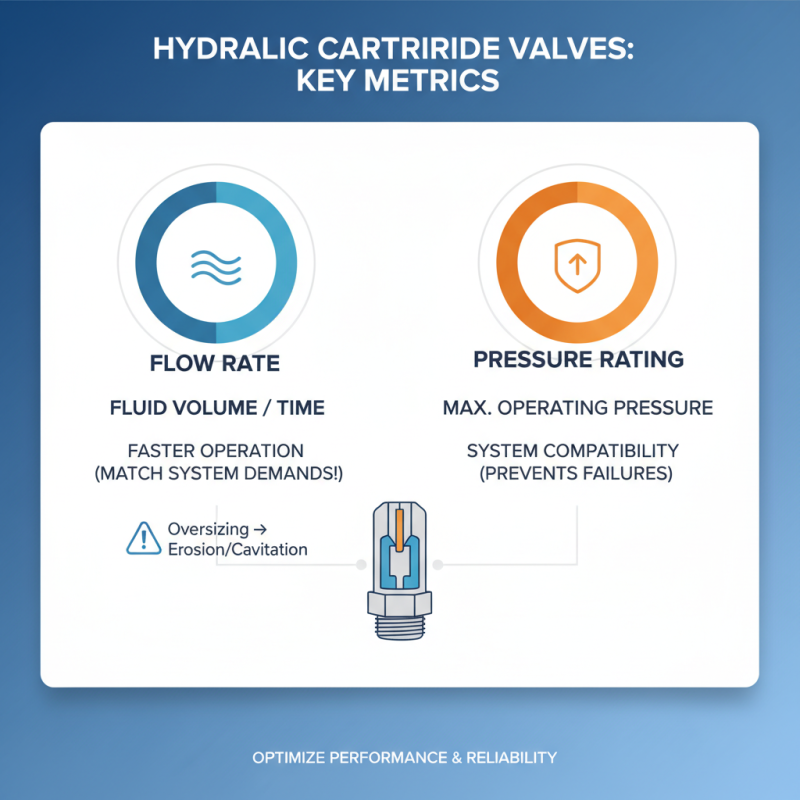

When choosing hydraulic threaded cartridge valves, performance metrics are crucial. Two key metrics stand out: flow rate and pressure ratings. The flow rate tells you how much fluid can pass through the valve in a given time. Typically, higher flow rates ensure faster operation. However, it’s essential to match flow rates with system demands. Oversized valves can lead to erosion and cavitation.

Pressure ratings are equally important. They indicate the maximum pressure the valve can handle. Using a valve above its rated pressure can cause failure. Always refer to specifications before making a choice. The right pressure rating ensures longevity and safety for your system.

Here’s a tip: measure your system’s peak demands. This will help you select a valve that won’t underperform or overwork. Also, consider your system's temperature. Some valves have temperature limits. If your system operates at high temperatures, you might need particular materials.

Another tip: don’t overlook maintenance. Regular checks on valves can prevent issues. Neglecting this can result in unexpected downtime. A small oversight can lead to costly repairs.

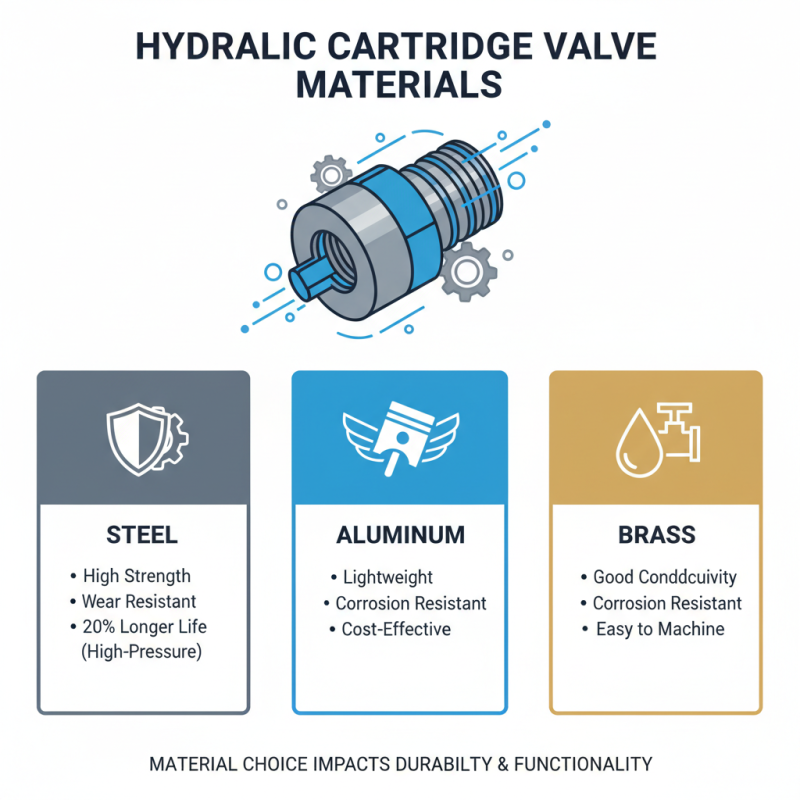

The material composition of hydraulic threaded cartridge valves significantly impacts their durability and functionality. Many valves are made from steel, aluminum, or brass. Each material offers unique benefits. For example, steel typically provides greater strength and resistance to wear. A recent industry report found that steel valves can last up to 20% longer in high-pressure environments compared to aluminum.

However, weight can be a concern. Aluminum is lighter, making it easier to install and maintain. This can lead to reduced labor costs, especially in applications requiring frequent replacements. Yet, some studies suggest that aluminum valves may fail under extreme conditions more quickly. Proper selection based on application specifics is crucial.

Brass valves, often seen as a cheaper alternative, can corrode faster than their steel or aluminum counterparts, especially in moist environments. Industry experts recommend regular maintenance to address this potential issue. Finding the right material involves weighing these factors against performance requirements. Keep in mind the trade-offs involved; sometimes, the cheapest option may not deliver the longevity expected.

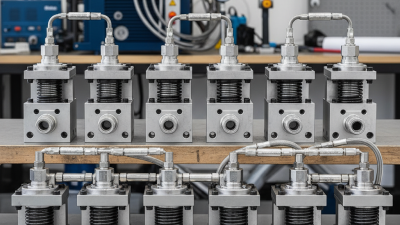

When selecting hydraulic threaded cartridge valves, understanding the market can be challenging. Many brands present various features and designs. It’s essential to compare these options based on performance metrics and reliability.

Some valves excel in flow rates, while others focus on pressure control. A few manufacturers emphasize durability in high-stress environments. This diversity can confuse buyers. Evaluating these parameters can help narrow down choices. Take note of the available sizes and installation requirements. Small differences can significantly impact system efficiency.

Cost is another factor. Higher-priced options don’t always guarantee better performance. Scrutinizing user reviews can expose flaws or weaknesses. Not every user will have a flawless experience. Always consider feedback on valve longevity and maintenance needs. In the end, careful analysis can reveal the best match for specific applications.

Maintaining hydraulic threaded cartridge valves is crucial for their longevity and performance. Regular inspections are essential. According to industry reports, over 25% of valve failures are attributed to lack of maintenance. Small leaks may seem minor but can cause significant wear over time. Monitoring for signs of wear can prevent catastrophic failures.

Proper lubrication is another key aspect. The right lubricant reduces friction and extends the lifespan of valves. Ensure seals are undamaged and clean. Dirty seals can lead to costly repairs and downtime. An estimated 15% of maintenance costs stem from preventable seal failures.

Also, consider temperature regulation. Overheating can cause severe damage to valves. Maintaining optimal temperature ranges is vital. Industry data suggests that operating valves outside recommended temperatures can decrease their lifespan by up to 30%. Regular temperature checks and adjustments can lead to improved reliability.