Leave Your Message

In the world of fluid power systems, efficiency and control are paramount, particularly in applications where precision is required. One innovative solution that has emerged to enhance these systems is the implementation of Stacked Counterbalance Valves. These advanced components play a critical role in managing fluid flow, providing both stability and responsiveness to dynamic loads. By effectively counteracting pressure fluctuations and preventing unintended motion, Stacked Counterbalance Valves transform the performance of hydraulic circuits. This introduction to the benefits and functionalities of these valves highlights their significance in optimizing system efficiency, reducing energy consumption, and improving overall operational reliability. As industries increasingly seek ways to enhance productivity and streamline processes, understanding the role of Stacked Counterbalance Valves becomes essential for engineers and practitioners alike.

Stacked counterbalance valves play a crucial role in enhancing fluid power systems by maintaining precise control over hydraulic motion. These specialized valves are designed to prevent uncontrolled load drop while allowing smooth operation, making them essential in applications like excavators and aerial work platforms. According to a report by the International Fluid Power Society, the global fluid power market is projected to reach $60 billion by 2025, highlighting the increasing importance of efficient hydraulic components in various industries.

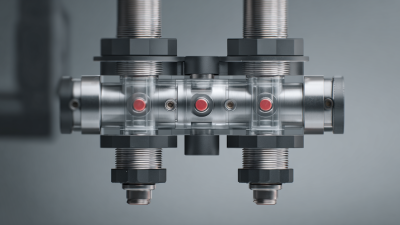

Understanding the fundamental mechanism behind stacked counterbalance valves is key to appreciating their impact. Unlike traditional counterbalance valves, stacked designs integrate multiple functions into a compact form, which significantly reduces the need for additional space and components. This design innovation not only simplifies system architecture but also improves response times. A study from the Fluid Power Journal indicates that using stacked counterbalance valves can enhance machine performance by up to 20%, reflecting their transformative effect on operational efficiency in fluid power systems.

Stacked counterbalance valves are revolutionizing fluid power systems by significantly enhancing efficiency and performance. These compact and integrated valves are designed to control load movement and maintain stability during operation, which is particularly critical in applications such as mobile machinery and industrial equipment. Their unique design allows for better load control with minimal pressure loss, leading to improved energy savings and faster response times.

The mechanics of these stacked valves facilitate a streamlined flow path, reducing the complexity of traditional valve arrangements. By stacking multiple valves together, they not only save space but also decrease the number of required connections and potential leak points. This results in a more reliable system with lower maintenance needs. Furthermore, the precise control offered by stacked counterbalance valves ensures that fluctuations in the load are managed effectively, which enhances the overall safety and consistency of fluid power operations. Their integration into hydraulic systems is paving the way for smarter, more efficient machinery that meets the demands of modern industry.

Stacked counterbalance valves are becoming increasingly crucial in fluid power applications,

offering significant benefits that enhance efficiency and reliability.

These valves provide load-holding capabilities that prevent unintended movement, especially in mobile machinery such as

scissors lifts and hydraulic heavy-duty mobile machines. The integration of advanced technologies into these systems

helps optimize performance, allowing for smoother operation and improved control under varying conditions, including

extreme temperatures.

Moreover, the rise of electric prime movers in hydraulic systems showcases the versatility of stacked counterbalance valves.

These valves work seamlessly with electro-hydraulic implement systems, ensuring consistent performance across a range of applications.

The continuous development of smart motion control technologies further emphasizes the importance of these valves,

as they contribute to energy efficiency and precision. By improving load management and enhancing the safety of operations,

stacked counterbalance valves are transforming the landscape of fluid power systems

and driving innovation in the industry.

When it comes to maximizing the efficiency of fluid power systems, the installation of stacked counterbalance valves is crucial. These valves are designed to control the flow of hydraulic fluid, ensuring that machines operate smoothly and reliably. According to a study by the National Fluid Power Association (NFPA), incorporating counterbalance valves can improve system efficiency by up to 30%, ultimately leading to lower operational costs and extended equipment lifespan.

To achieve optimal performance during installation, it's vital to ensure proper orientation and alignment of the valves. Misalignment can lead to unintended pressure drops and flow restrictions, which compromise the system's functionality. Furthermore, using the right seals and fittings is essential to prevent leaks. Tip: Always refer to manufacturer guidelines and specifications for tightening torque and assembly instructions to maintain the integrity of the hydraulic circuit.

Additionally, regular maintenance and monitoring of stacked counterbalance valves play a significant role in sustaining their effectiveness. Implementing a routine inspection schedule can help identify issues before they escalate. Tip: Consider integrating advanced diagnostic tools to track performance data, which can provide insights into wear patterns and potential failures, ensuring prompt action can be taken to address any irregularities.

| Installation Step | Description | Best Practices | Expected Outcome |

|---|---|---|---|

| Site Preparation | Ensure the installation area is clean and free from debris. | Conduct a thorough site assessment before installation. | Minimized risk of contamination during valve installation. |

| Component Selection | Choose compatible stacked counterbalance valves for your system. | Consult manufacturer specifications for compatibility. | Enhanced performance and reliability of the fluid power system. |

| Installation Process | Install the counterbalance valves according to the layout plan. | Follow detailed installation manuals and guidelines. | Optimal positioning for maximum efficiency. |

| System Testing | Evaluate the system after installation for leaks and functionality. | Perform pressure tests and functionality checks. | Assured reliability and performance of the system. |

| Maintenance | Establish a regular maintenance schedule. | Use manufacturer-recommended maintenance procedures. | Extended lifespan and efficiency of counterbalance valves. |

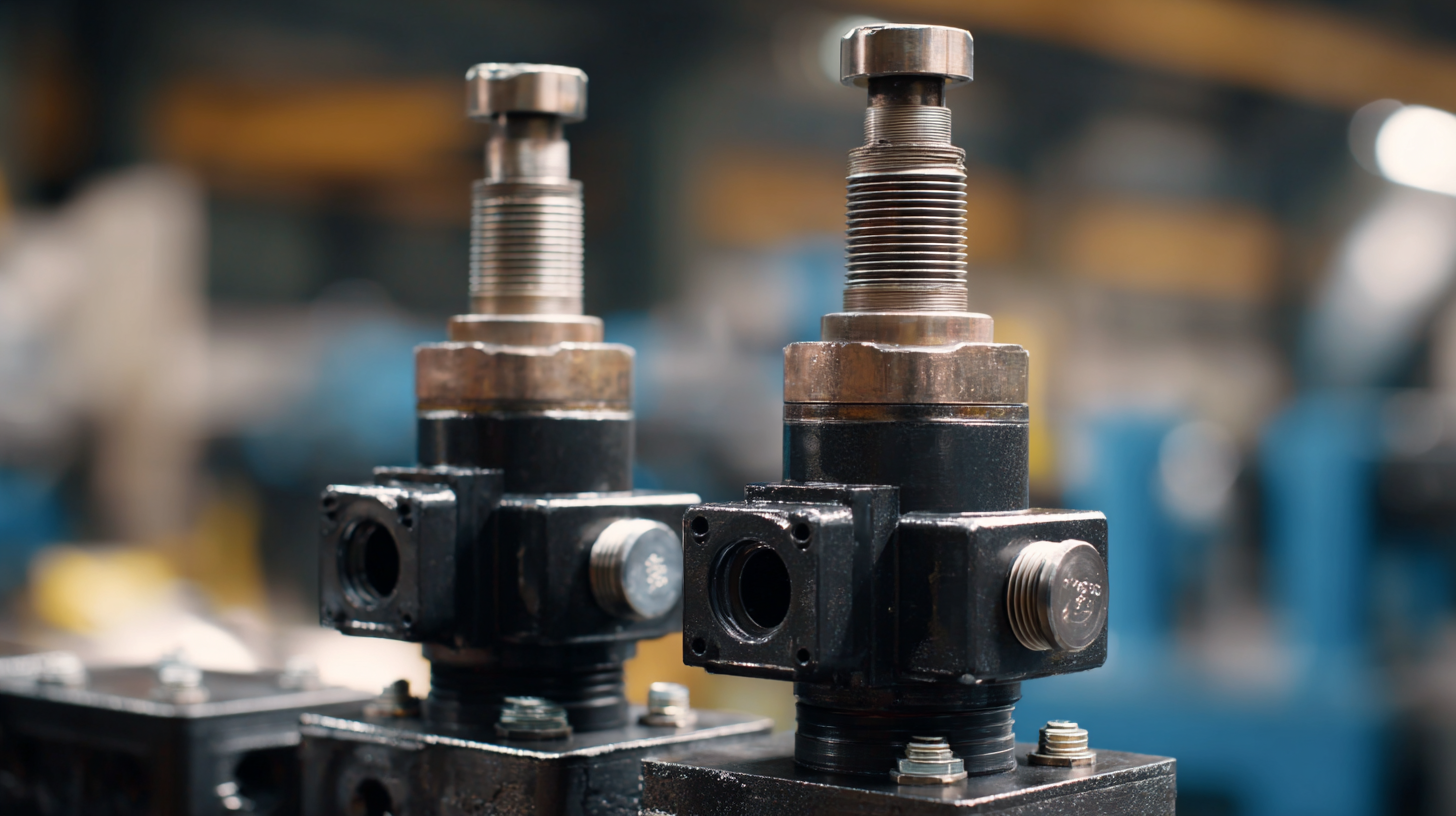

Stacked counterbalance valves are critical in fluid power systems, offering precise control over load handling and enhancing overall efficiency. However, like any hydraulic component, they can encounter issues that compromise performance. One common problem is incorrect adjustment settings, which can lead to erratic load control and instability. Technicians must ensure that the valves are calibrated to the specific requirements of the system to prevent operational failures.

Another issue often faced is the ingress of contaminants into the hydraulic fluid. Contamination can cause valve sticking or failure, leading to performance losses. Regular maintenance and filtration are essential to keep the hydraulic circuits clean and functioning optimally. Additionally, proper inspection of seals and connections can identify potential leaks that may lead to air entering the system, which can severely impact the efficacy of stacked counterbalance valves. By addressing these common issues proactively, operators can maintain the reliability and efficiency of their fluid power systems.