Leave Your Message

In the realm of fluid control systems, the optimization of flow management is crucial for enhancing efficiency and performance across various industries. A pivotal component in achieving this optimization is the use of Unidirectional Throttle Valves. According to a recent report by the TechIndustry Research Group, the implementation of these valves can reduce energy consumption by up to 30% in hydraulic systems, showcasing their vital role in promoting sustainability and cost-effectiveness. As industries continue to evolve towards more efficient operations, the importance of reliable components like Unidirectional Throttle Valves cannot be overstated.

Moreover, a survey conducted by the Global Valve Association indicated that approximately 70% of fluid control engineers prioritize unidirectional mechanisms for their ability to maintain consistent pressures and flow rates, which is essential for processes requiring precision and stability. As the landscape of industrial automation grows more complex, the effectiveness of Unidirectional Throttle Valves in regulating the direction and volume of fluid flow ensures that systems operate at peak performance. Their reliability and efficiency make them an indispensable part of modern fluid control strategies, paving the way for innovations and advancements in technology. Thus, understanding the intricacies of these valves is essential for anyone looking to optimize fluid control systems in the coming years.

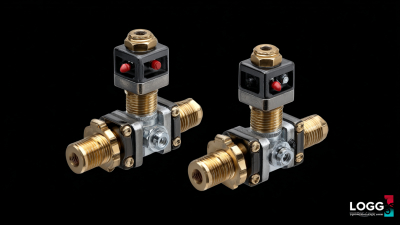

Unidirectional throttle valves play a critical role in fluid dynamics, ensuring precise control over the flow of liquids and gases within a system. By allowing fluid to flow in one direction while restricting reverse flow, these valves help maintain desired pressure levels and regulate flow rates. This unidirectional control is vital in various applications, from hydraulic systems in heavy machinery to intricate setups in chemical processing plants, where maintaining the integrity of the flow is paramount.

The significance of unidirectional throttle valves extends beyond mere flow regulation. They contribute to the overall efficiency and reliability of fluid control systems while minimizing the risk of damage caused by backflow. By preventing reverse pressure conditions, these valves protect sensitive components and enhance system performance. As industries increasingly adopt automated solutions, the precision offered by unidirectional throttle valves becomes indispensable, ensuring that fluid control processes operate smoothly and effectively.

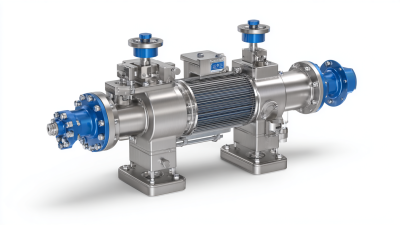

Unidirectional throttle valves play a crucial role in optimizing fluid control systems across various industries. With their ability to regulate flow in one direction while preventing backflow, these components significantly enhance system efficiency. According to a report by the International Society of Automation, implementing unidirectional throttle valves can improve flow control precision by up to 30%, leading to enhanced operational efficiency and reduced energy consumption.

One of the key advantages of unidirectional throttle valves is their ability to minimize the risk of cavitation, which can lead to system failures and costly repairs. A study conducted by the American Society of Mechanical Engineers found that systems incorporating unidirectional valves experienced a 25% reduction in maintenance costs, as these valves effectively prevent the sudden pressure drops that often cause cavitation. Additionally, their compact design allows for easy integration into existing systems, making them an ideal choice for retrofitting or upgrading fluid control processes. This not only simplifies installation but also enhances the overall reliability of the system, allowing for smoother and more efficient operations.

Unidirectional throttle valves play a crucial role in optimizing fluid control systems across various industries. In hydraulic and pneumatic systems, these valves are designed to allow fluid to flow in one direction while restricting it in the opposite direction. This functionality is vital in applications such as automotive braking systems, where controlled flow helps maintain the efficiency and safety of the system. By preventing backflow, unidirectional throttle valves ensure that the brakes engage precisely and function as intended.

In the manufacturing sector, unidirectional throttle valves are instrumental in controlling the speed of actuators. They enable precise adjustments to fluid flow, which is essential for maintaining consistent performance in automated processes. Industries such as food and beverage, chemicals, and pharmaceuticals benefit from their ability to maintain strict flow rates, ensuring product quality and compliance with regulations. Furthermore, in HVAC systems, these valves help regulate air and refrigerant flow, enhancing system efficiency and reducing energy consumption, ultimately contributing to a more sustainable operational framework across different sectors.

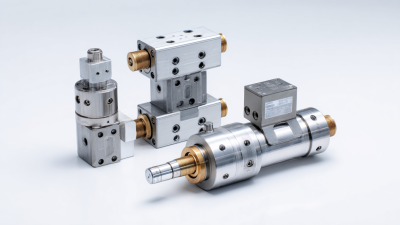

Fluid control systems rely heavily on unidirectional throttle valves to maintain optimal performance. Without these critical components, systems face significant challenges, such as backflow and pressure fluctuations, which can lead to inefficiencies and increased operational costs. A recent industry report from the Fluid Controls Association indicates that improper fluid management can increase energy consumption by up to 30%. This emphasizes the importance of unidirectional valves in maintaining a stable and efficient fluid flow.

To address the challenges encountered in fluid control without unidirectional valves, engineers can explore alternative solutions like using check valves or pressure relief valves. However, these options often fail to deliver the precise control needed in various applications. For instance, the American Society of Mechanical Engineers (ASME) highlights that systems lacking unidirectional control can lead to inconsistent pressure readings, complicating flow regulation and leading to potential system failures.

**Tip:** Regularly inspect your fluid control system to identify areas where unidirectional throttle valves can be integrated. This proactive approach can significantly enhance system reliability and efficiency. Additionally, consider implementing predictive maintenance strategies, as they can help preemptively address potential failures associated with fluid control issues.

| Dimension | Description | Importance | Challenges Without | Solutions |

|---|---|---|---|---|

| Flow Control | Regulated movement of fluid in a desired direction. | Critical for efficiency and safety in systems. | Risk of backflow and uncontrolled flow rates. | Implementing check valves or advanced control algorithms. |

| Pressure Regulation | Maintaining optimal pressure levels in the system. | Prevents equipment damage and ensures operational integrity. | Pressure spikes and drops can cause failures. | Use of pressure relief valves and real-time monitoring. |

| Energy Efficiency | Minimizing energy consumption within systems. | Cost savings and reduced environmental impact. | Excess energy usage due to inefficiencies. | Incorporating variable speed drives and proper sizing. |

| System Reliability | Ensuring that fluid control systems operate continuously without failure. | Critical for production and operational uptime. | Possible leaks or blockages affecting system performance. | Regular maintenance and redundancy in design. |

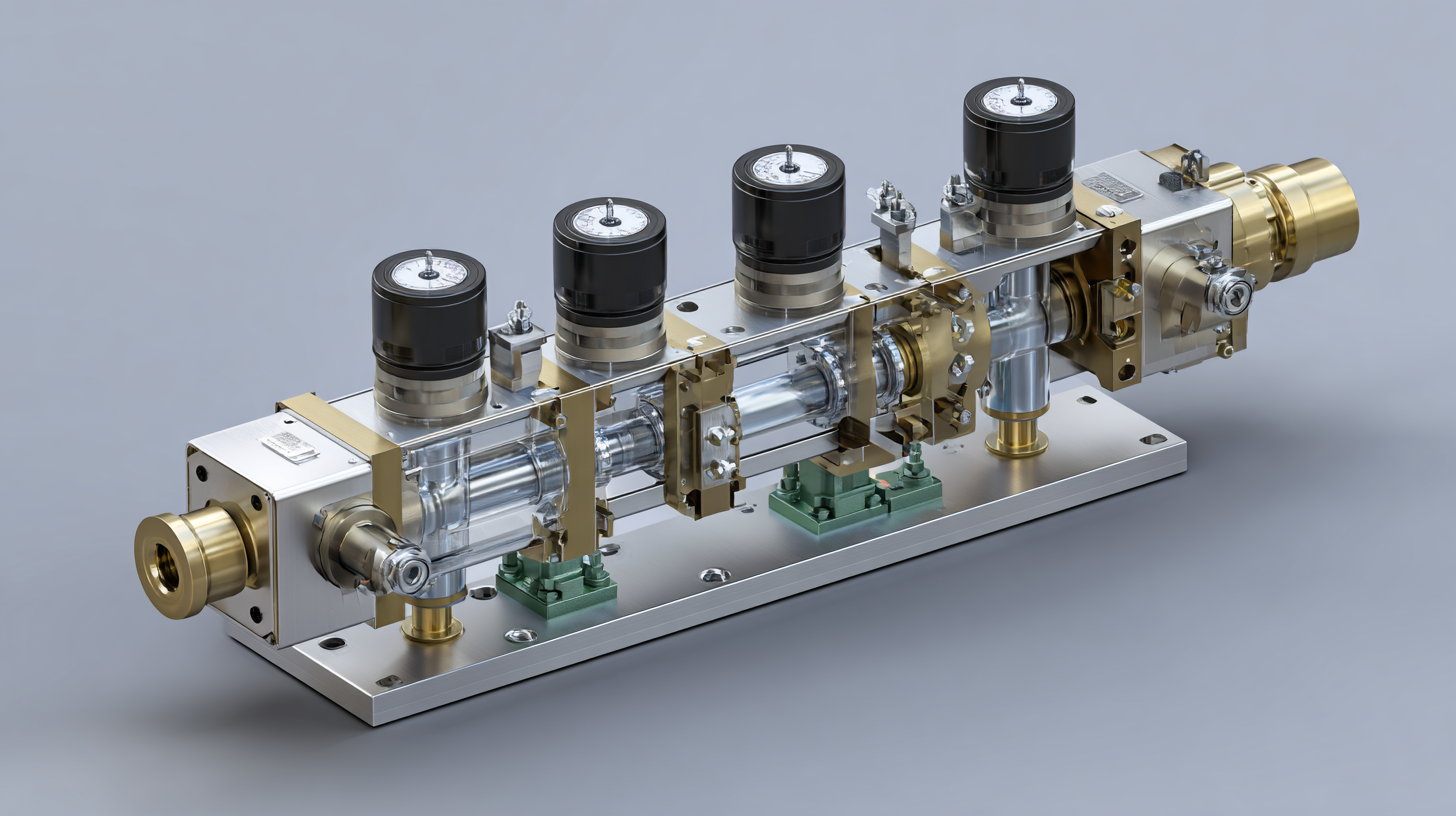

In fluid control systems, the choice between

unidirectional and

bidirectional throttle valves can significantly impact performance.

Unidirectional throttle valves allow fluid to flow in a single direction, which provides

precise control over flow rates and pressure. This design minimizes the risk of flow reversals that can lead to

instability in the system, making it ideal for applications where consistent fluid delivery is critical.

By limiting flow direction, unidirectional systems enhance

reliability and reduce maintenance needs, ultimately leading to

longer equipment lifespan.

Conversely,

bidirectional throttle valves offer the flexibility to control fluid flow in both directions, which can be advantageous in certain scenarios.

However, this dual functionality may result in

increased complexity and decreased efficiency, as the system must account for the potential of flow reversal.

In many cases, the unpredictability associated with bidirectional systems can lead to challenges in maintaining optimal performance.

As a result, unidirectional throttle valves are increasingly favored in applications demanding

high levels of efficiency and stability, showcasing their essential role in modern fluid control system design.