Leave Your Message

In the evolving landscape of hydraulic systems, understanding Pressure Directional Valves is vital for industry professionals aiming to maximize efficiency and performance. These valves play a critical role in controlling the flow and direction of hydraulic fluid within a circuit, significantly impacting the functionality of various machinery and equipment. As industries move toward more sophisticated and diverse applications, recognizing the key specifications associated with Pressure Directional Valves becomes essential for making informed decisions. This article will explore the essential criteria for selecting these valves, highlight emerging trends shaping their development, and provide insights into best practices for implementation. By diving deep into the intricacies of Pressure Directional Valves, readers will gain a comprehensive understanding of their importance in hydraulic systems, equipping them with the knowledge to optimize their operations effectively.

Pressure directional valves are crucial components in hydraulic systems, enabling the management of fluid flow and pressure. When identifying key specifications of these valves, it is essential to consider factors such as flow rate, operating pressure, and response time. According to a recent market analysis by Research and Markets, the global hydraulic valves market is projected to grow at a CAGR of 4.2% from 2023 to 2028, underscoring the increasing demand for efficient hydraulic solutions.

In particular, flow rate specifications indicate how much hydraulic fluid the valve can manage effectively. Most industrial applications require valves that can handle flow rates between 5 to 150 liters per minute, depending on the system's design. Additionally, operating pressure ratings typically range from 70 bar to 350 bar, making it critical to select valves that match the operational requirements to avoid potential failures. Furthermore, response time plays a pivotal role in precision applications; valves with quicker activation times enhance system responsiveness and efficiency. As the hydraulic industry evolves, focusing on these key specifications will enable engineers and operators to maximize system performance.

Pressure directional valves play a pivotal role in hydraulic systems, as their design significantly impacts system efficiency. According to a report by the International Fluid Power Society, hydraulic systems equipped with high-performance pressure directional valves can achieve up to 20% greater efficiency compared to those using standard valves. This efficiency gain can be attributed to precise control over fluid flow direction, allowing for optimized power distribution in machinery. As industry demands evolve, manufacturers are increasingly focused on developing valves that minimize pressure loss and enhance responsiveness.

One of the key trends in the market is the integration of intelligent controls with pressure directional valves. The 2022 Hydraulics Global Market Outlook indicated that the incorporation of smart technologies leads to a reduction in energy consumption by approximately 30%, thus improving overall system performance. These advancements allow for real-time monitoring and adjustment of valve settings, resulting in more robust and adaptive hydraulic systems. As industries continue to prioritize sustainability and efficiency, the impact of pressure directional valves on system productivity and energy usage becomes increasingly crucial.

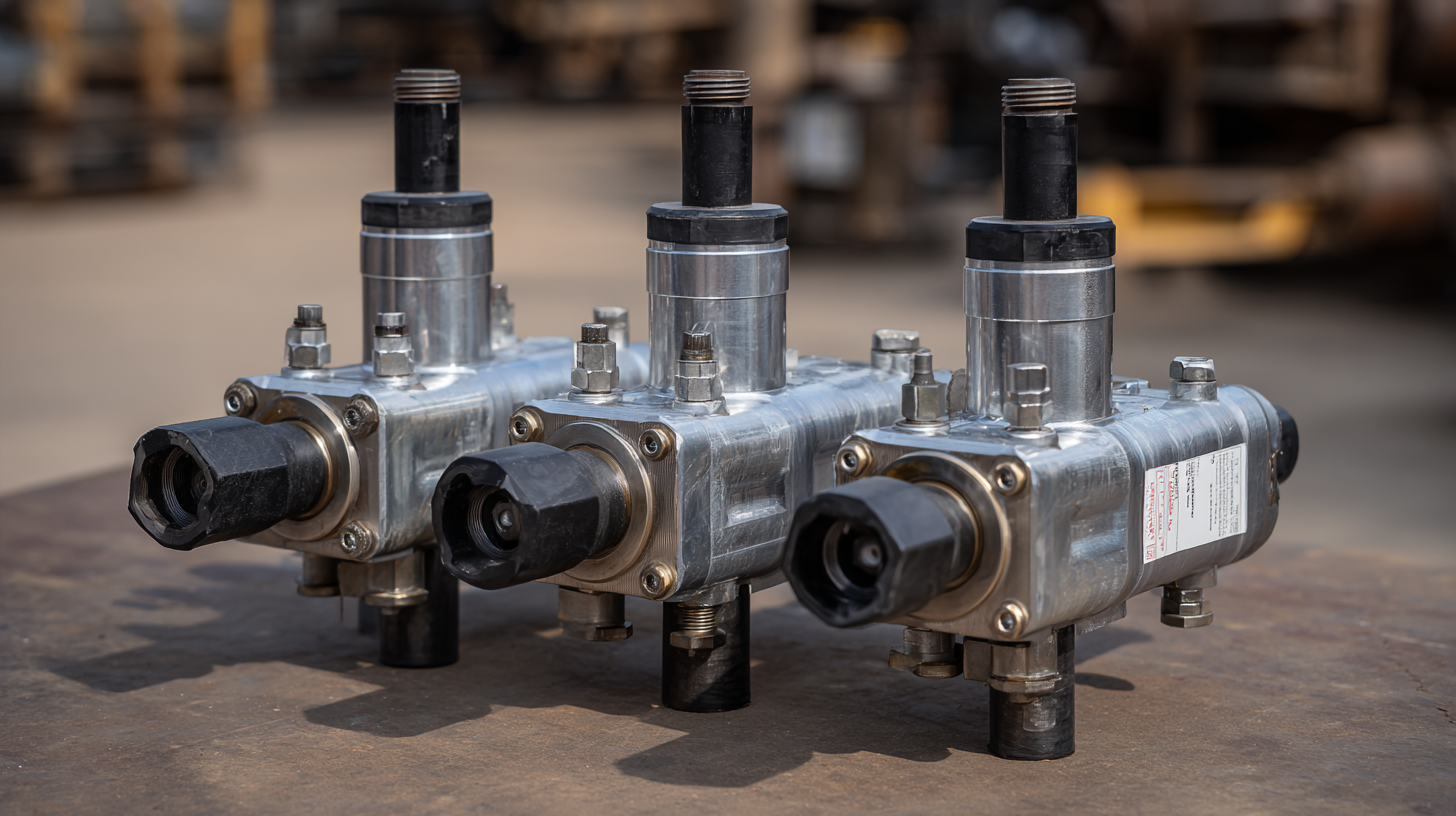

Pressure directional valves are crucial components in hydraulic systems, used to control the flow and pressure within the system. Differentiating between various types of pressure directional valves involves understanding their design and operational principles. This differentiation primarily revolves around the valve actuation method—manual, pilot-operated, and electrically operated. Manual valves require operator intervention, while pilot-operated valves offer more precise control via hydraulic pressure and electrically operated valves enable remote operation.

Another critical aspect is the valve configuration, which includes spool and poppet designs. Spool valves utilize a sliding mechanism that can direct fluid in multiple paths, depending on its position, while poppet valves operate like switches, opening or closing the flow based on the valve's state. Additionally, different pressure ratings and flow capacities can affect a valve’s suitability for specific applications. By carefully evaluating these characteristics, engineers can select the appropriate valve to optimize hydraulic system performance and efficiency.

Staying updated on industry trends affecting pressure directional valves in hydraulic systems is essential for professionals looking to maintain a competitive edge. One effective way to keep informed is through subscribing to specialized industry publications and newsletters. These resources provide insights into new technologies, regulatory changes, and emerging market demands that directly influence the design and application of pressure directional valves. Engaging with these materials regularly ensures that professionals are aware of the latest innovations and standards shaping the industry.

Additionally, attending trade shows and conferences can be invaluable for networking and gaining firsthand knowledge about trends in hydraulic systems. These events often feature expert panels, product demonstrations, and seminars that cover a range of topics, from advancements in valve technology to best practices for implementation. By actively participating in these gatherings, individuals can not only learn from industry leaders but also gain access to practical advice and solutions that are crucial for adapting to evolving market conditions.

| Specification | Description | Current Trends |

|---|---|---|

| Pressure Rating | Typical ratings range from 10 bar to 700 bar depending on the application. | Increased demand for high-pressure applications in construction and industrial sectors. |

| Flow Rate | Measured in liters per minute (L/min), with common ranges from 5 L/min to 500 L/min. | Growing preference for valves that offer adjustable flow rates for improved efficiency. |

| Valve Type | Includes directional control valves, pressure relief valves, and proportional valves. | Shift towards electronic and proportional control systems for better precision. |

| Material | Common materials include cast iron, aluminum, and stainless steel. | Increased use of lightweight materials for efficiency gains in mobile applications. |

| Size | Valves come in a variety of sizes to fit different pipeline diameters, from small to large. | Trend towards compact and modular designs for easier integration into existing systems. |

Pressure directional valves are critical components in hydraulic systems, directing fluid flow and managing pressure within the system. Proper maintenance is essential for ensuring their effective operation. Regular inspection and cleaning of the valves can prevent the accumulation of dirt and debris, which may lead to malfunctions. It's also important to check for signs of wear, such as leaks or unusual noise during operation, as these can indicate the need for repairs or replacement.

Troubleshooting pressure directional valves requires a systematic approach. First, operators should verify that the valve is receiving the correct electrical signals, as failures in solenoid operation can disrupt functionality. Next, it's crucial to assess the hydraulic fluid quality; contaminated or degraded fluid can impair valve performance. If issues persist, testing the valve's internal components, such as springs and seals, may be necessary to identify underlying problems. By following these maintenance and troubleshooting steps, operators can ensure that pressure directional valves continue to perform effectively within hydraulic applications.