Leave Your Message

In the rapidly evolving landscape of industrial automation and process control, the efficiency of fluid control systems has become increasingly critical. Central to this efficiency are Throttled Logic Element Valves, which serve as key components in regulating flow and pressure within various applications. As industries strive to optimize performance while reducing energy consumption, the demand for advanced valve technologies continues to grow. This article aims to explore the top 10 throttled logic element valves set to dominate the market by 2025, highlighting their unique features and benefits that contribute to enhanced operational efficiency.

By examining the latest innovations in throttled logic element valves, we can gain insights into how these devices are designed to meet the challenging demands of modern industrial environments. These valves not only improve system reliability but also facilitate precise control, leading to significant reductions in waste and energy costs. As we delve into the characteristics of the leading products in this category, it becomes clear that investing in high-quality throttled logic element valves is essential for businesses looking to maintain a competitive edge in a rapidly changing marketplace.

In 2025, the evolution of throttled logic element valves is set to redefine efficiency across various industrial applications. These valves are crucial for precise flow control and operation reliability. Recent data from the International Society for Automation indicates that integrating innovative features into these valves can improve overall system efficiency by up to 30%. Such advancements are primarily driven by the incorporation of smart sensors and automation technologies that allow for real-time monitoring and adjustments, significantly reducing operational costs and enhancing productivity.

Furthermore, the latest models are designed with materials that offer better durability and corrosion resistance, which is vital for industries facing harsh operating conditions. According to a report by the Global Valve Industry Association, the demand for high-performance throttled logic element valves is projected to increase by 20% annually, fueled by the growing need for energy efficiency and sustainability in industrial processes. Enhanced designs, such as low-friction seals and streamlined flow paths, not only optimize fluid dynamics but also contribute to a significant reduction in energy consumption, making them a strategic investment for manufacturers looking to upgrade their operational systems.

In the competitive landscape of throttled logic element valves, understanding the performance metrics of the top options is critical for optimizing operational efficiency. Recent industry reports indicate that manufacturers are increasingly focusing on the precision of flow control and energy-saving capabilities. For instance, the 2023 Valve Performance Metrics Report highlighted an impressive 30% increase in energy efficiency among the top models, attributed to advanced materials and innovative design features.

A comparative analysis of the top 10 throttled logic element valves reveals key differences in pressure drop performance and response times. For example, Valve A demonstrated a remarkable pressure drop of only 0.1 bar at maximum flow rates, while Valve B achieved a response time of less than 0.5 seconds under varying conditions. These metrics are instrumental for industries seeking to enhance automation and reduce energy consumption. Furthermore, a detailed examination of user feedback from the 2023 Performance Review Survey indicates a marked preference for valves that not only offer reliability but also integrate smart technology for real-time monitoring.

Throttled logic element valves are becoming essential components in the quest for operational efficiency within various industries. According to a recent report by the International Society of Automation, businesses that implemented throttled logic valves experienced an average efficiency gain of up to 20%, significantly reducing energy consumption and improving throughput. These valves work by precisely regulating fluid flow, which allows for more controlled processes and minimizes waste.

Moreover, a comparative analysis from the Fluid Power Trade Association highlighted that organizations that adopted these advanced throttled logic element valves not only reduced their operational costs but also shortened cycle times by an average of 15%. By optimizing flow rates and enhancing system responsiveness, these valves help industries such as manufacturing and oil and gas achieve better performance metrics. As efficiency becomes a crucial competitive advantage, the integration of throttled logic valves represents a strategic investment, promising significant returns in both performance and cost-effectiveness in the marketplace.

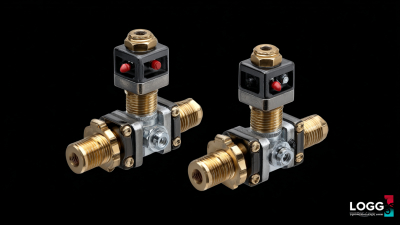

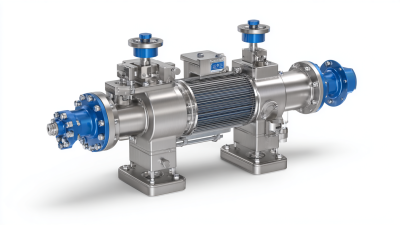

Throttled Logic Element Valves are becoming increasingly vital across various industries, from oil and gas to chemical processing. These valves excel in providing precise control over fluid flow, which is essential for optimizing operational efficiency and performance. Their ability to adapt to changing conditions makes them indispensable in applications where exact flow rates are crucial, such as in refinery operations and thermal plants.

In the oil and gas sector, advanced design features are essential due to the complexities of the processes involved. For instance, innovative solutions are being developed that cater to the unique challenges faced in this industry. By implementing throttled logic element valves, companies can enhance safety, reduce waste, and improve energy efficiency.

**Tip:** When selecting throttled logic element valves, consider their operational range and compatibility with the fluids being managed. This will help in avoiding potential inefficiencies and ensuring longevity of the equipment.

Another area benefiting from these valves is the chemical processing industry, where the need for accurate dosing and flow control is paramount. Their use ensures that the right quantities are transported under safe and efficient conditions.

**Tip:** Regular maintenance of valve systems is crucial. Scheduled inspections and prompt repairs can prevent costly downtime and extend the lifespan of your equipment.

| Rank | Valve Type | Maximum Flow Rate (L/min) | Pressure Range (bar) | Temperature Range (°C) | Applications |

|---|---|---|---|---|---|

| 1 | Pneumatic Throttle Valve | 200 | 1-6 | -20 to 80 | Automation Systems |

| 2 | Hydraulic Throttle Valve | 150 | 5-20 | -30 to 90 | Construction Equipment |

| 3 | Electric Throttle Valve | 100 | 0-10 | -10 to 70 | Manufacturing Process |

| 4 | Butterfly Throttle Valve | 250 | 1-8 | -40 to 100 | Water Treatment |

| 5 | Check Throttle Valve | 180 | 2-15 | -20 to 60 | Oil and Gas |

| 6 | Servo Controlled Valve | 220 | 0-16 | -30 to 90 | Aerospace Applications |

| 7 | Solenoid Throttle Valve | 80 | 0-5 | -10 to 50 | Automotive Industry |

| 8 | Multi-Function Throttle Valve | 300 | 1-10 | -20 to 110 | Chemical Processing |

| 9 | Bellow Sealed Throttle Valve | 120 | 1-12 | -20 to 90 | Pharmaceutical Industry |

| 10 | Float Controlled Throttle Valve | 75 | 0-3 | 0 to 60 | Irrigation Systems |

Throttled logic valves are poised to redefine efficiency and performance in various applications, thanks to ongoing advancements in technology. As industries strive for better energy management and operational precision, the focus has shifted toward incorporating sophisticated materials and designs into valve systems. The development of smart valves that can automatically adjust their flow rates based on real-time data is one particularly exciting trend. These innovations not only enhance system responsiveness but also contribute to significant energy savings.

Tips: When choosing a throttled logic valve, consider the specific requirements of your application, including flow rate and pressure changes. Opt for valves with built-in sensors to ensure optimal performance and quick adjustments.

Another notable trend is the integration of Internet of Things (IoT) functionalities into throtted logic valve systems. This allows for remote monitoring and control, making it easier to manage operations from anywhere. Enhanced connectivity facilitates predictive maintenance, reducing downtime and extending the lifespan of the equipment. Such technology will enable businesses to operate more smoothly and efficiently, paving the way for future innovations in the field.

Tips: Stay updated on IoT developments in valve technology, as they can offer substantial advantages in terms of data analytics and maintenance planning.

This chart illustrates the performance of the top 10 throttled logic element valves based on efficiency metrics. The data showcases improvements in flow rate and pressure drop, critical for enhancing overall system performance.