Leave Your Message

Stacked Counterbalance Valves play a crucial role in hydraulic systems. They control the movement of a load, ensuring safety and stability. These valves prevent unintended motion, making them essential in many applications.

In a world where hydraulic precision is vital, knowing the top options is helpful. Our exploration of the top 10 Stacked Counterbalance Valves will showcase leading choices in the market. Each valve has unique features and specifications, influencing performance and reliability.

Choosing the right valve can be overwhelming. Some brands might fall flat on promises. Research and understanding are necessary. As we delve into the various models, consider your needs carefully. A perfect fit can significantly enhance efficiency in hydraulic operations.

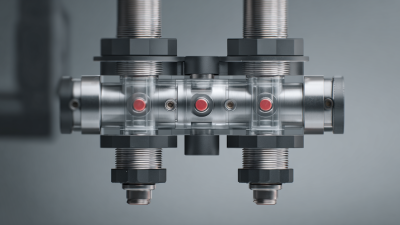

Stacked counterbalance valves play a crucial role in hydraulic systems. They help control load movements, making them essential in many applications. These valves manage descending motion. This prevents unexpected drops and ensures safety. They provide stability under various conditions, which is vital for operators. The design often allows for easy integration into existing systems.

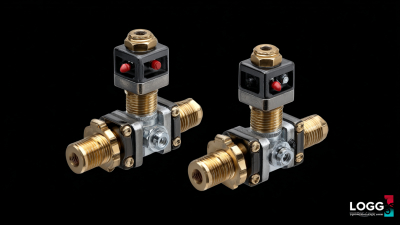

There are several types of stacked counterbalance valves. Each type has unique features and benefits. Their function can vary based on the application. Some are better for heavy loads. Others work well in high-speed scenarios. Users must be aware of their specific needs. Misalignment between the valve type and application can lead to inefficiencies. It's important to choose wisely and evaluate performance.

Potential issues may arise during operation. Pressure settings must be managed carefully to avoid damage. Over time, components may wear out or leak. This can affect the valve's ability to provide counterbalance. Regular maintenance is essential for longevity and performance. Users must remain vigilant to notice early signs of failure. Continuous improvement in understanding these valves can enhance overall system reliability.

This chart illustrates the key features of the top 10 stacked counterbalance valves, showcasing their flow rates (L/min) and pressure ratings (Bar). These metrics are critical for understanding their performance and application suitability.

Stacked counterbalance valves are essential in hydraulic systems. These components manage load holding and provide stability during operation. They prevent uncontrolled movement of machinery, especially in heavy-duty applications. According to a recent industry report, about 60% of hydraulic failures can be traced back to inadequate load management. This highlights the critical role of reliable counterbalance valves.

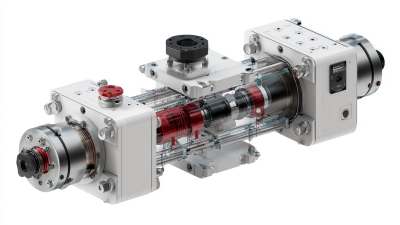

Key features of stacked counterbalance valves include integrated pressure control and efficient flow paths. Their design minimizes pressure losses, resulting in better system efficiency. The valves also adapt quickly to load fluctuations. This adaptability is crucial in applications like construction equipment and aerial lifts, where load dynamics can change rapidly. In fact, effective load control can enhance operational safety by reducing the risk of sudden drops.

While these valves provide significant benefits, there are challenges in their design and operation. For example, heat buildup can decrease valve performance. Furthermore, improper installation can lead to malfunction, risking equipment and personnel safety. Regular maintenance is needed to ensure reliability. This complexity often needs careful consideration from engineers and technicians handling hydraulic systems.

In the realm of hydraulic technology, stacked counterbalance valves play a crucial role. These valves control motion in hydraulic systems. They ensure stability and precision during operations. Many organizations rely on them for seamless performance. Industry reports indicate that the global market for hydraulic valves is poised to grow significantly, expecting a 6% increase over the next five years.

Several manufacturers are leading the charge in stacked counterbalance valve technology. They focus on innovation and efficiency. According to a recent industry analysis, improved designs have led to more compact units. These advances enhance performance in confined spaces. However, it’s crucial to note that not all products meet stringent standards. Some units suffer from reliability issues. Users must research thoroughly before making purchases.

Quality varies widely across manufacturers. Some brands consistently deliver top-notch performance. Others may compromise on key features. A comprehensive understanding of your project's specific needs is essential. Choose wisely; it can impact overall system efficiency significantly. Despite advancements, ongoing challenges remain in achieving universal reliability. Continuous development and feedback are vital for the industry's progress.

| Model | Pressure Rating (psi) | Flow Rate (gpm) | Weight (lbs) | Features |

|---|---|---|---|---|

| Model A | 3000 | 20 | 15 | High Flow Capability |

| Model B | 3500 | 25 | 18 | Compact Design |

| Model C | 4000 | 30 | 20 | Integrated Circuitry |

| Model D | 4500 | 28 | 22 | Easy Maintenance |

| Model E | 5000 | 35 | 25 | Durable Construction |

| Model F | 3200 | 15 | 16 | Variable Speed |

| Model G | 3500 | 22 | 19 | Safety Features |

| Model H | 4200 | 18 | 21 | Low Leakage |

| Model I | 4600 | 29 | 24 | Advanced Modulation |

| Model J | 5000 | 32 | 27 | High Efficiency |

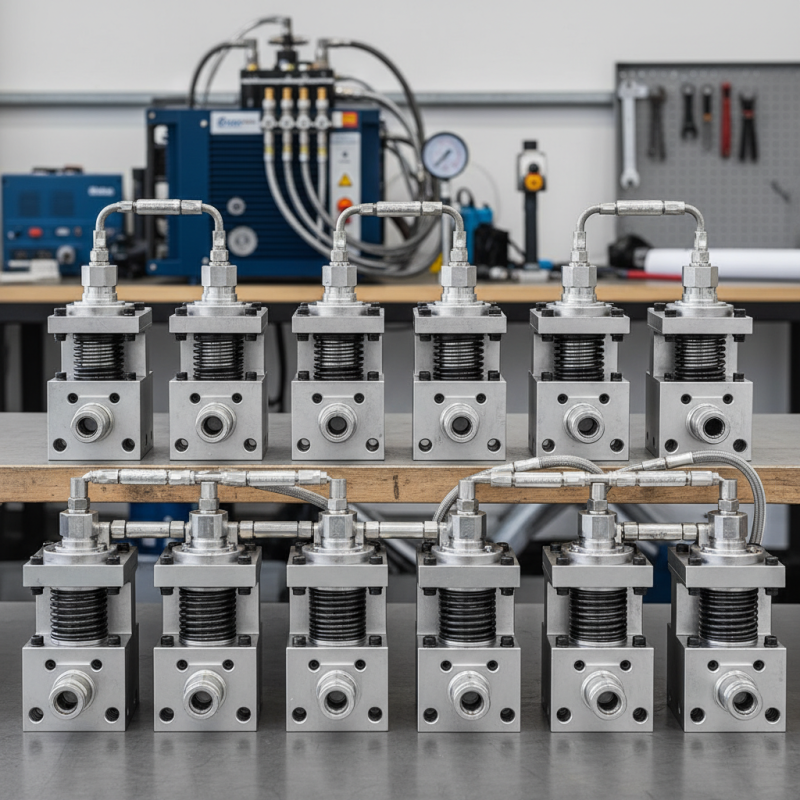

Stacked counterbalance valves are essential in various applications. They ensure that loads remain stable under different conditions. This stability is crucial in mobile equipment, construction machines, and material handling systems.

In a construction site, these valves control hydraulic cylinders. They prevent uncontrolled movements of heavy loads. This adds a layer of safety. Similarly, in automotive applications, they allow for smooth operation of lifts. Yet, improper settings can lead to unexpected issues, like jerky movements or excessive wear.

Marine and industrial environments also benefit from these valves. In cranes and hoists, counterbalance valves help manage loads efficiently. However, users often overlook maintenance. Neglecting small adjustments can lead to inefficiencies. Maintaining the right balance is crucial for optimal performance.

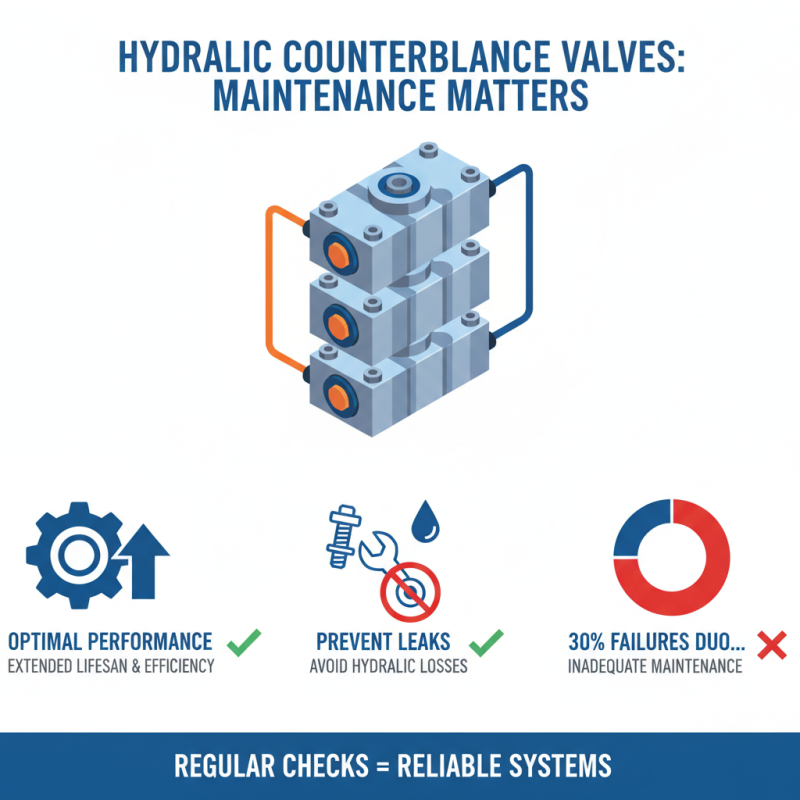

Maintaining stacked counterbalance valves is crucial for ensuring optimal performance. Proper maintenance can extend their lifespan and enhance efficiency. Regularly checking for leaks can prevent significant losses in hydraulic systems. According to industry reports, nearly 30% of hydraulic failures are attributed to inadequate maintenance practices.

Flushing the hydraulic fluid periodically is essential. Contaminants can build up in the system, leading to malfunction. It's recommended to flush the system at least once a year, or more frequently if working in dirty environments. This issue often gets overlooked, yet it can make a sizeable difference in operational efficiency.

Operators must also inspect the seals and O-rings. A simple crack might lead to pressure drops. Industry data show that about 20% of valve issues arise from seal failure. Regular inspections can catch these problems early, saving time and costs in repairs. Maintenance takes effort but is worth it for reliable performance.