Leave Your Message

In the evolving landscape of industrial automation and hydraulics, the significance of selecting the right Pilot Operated Check Valve (POCV) cannot be overstated. According to a recent report by MarketsandMarkets, the global check valves market is projected to reach USD 10.1 billion by 2025, driven by the increasing demand for efficient fluid control systems across various industries, including oil and gas, water treatment, and manufacturing.

Pilot Operated Check Valves are particularly vital due to their ability to maintain flow in hydraulic systems while preventing backflow, thereby enhancing safety and efficiency. As industries continue to embrace automation, understanding the nuances of choosing the optimal POCV is essential for maximizing operational reliability and minimizing maintenance costs.

In this blog, we will explore seven essential tips to help you navigate the selection process and align it with your specific industrial needs.

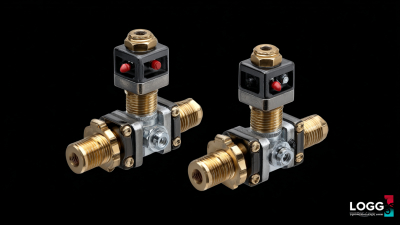

When it comes to selecting pilot operated check valves for industrial applications, understanding the various types available is crucial. These valves ensure unidirectional flow while allowing for easy flow reversal upon demand. Generally, there are two main types of pilot operated check valves:

integral types and external types.

Integral pilot operated check valves feature an internal pilot mechanism, which allows them to be more compact and efficient. On the other hand, external pilot operated check valves connect to an external pilot line, offering more flexibility in certain applications.

In addition to the design differences, it's also essential to consider the materials used in the construction of these valves. For instances in aggressive environments, materials such as stainless steel or specialized polymers may provide enhanced durability and resistance to corrosion. Additionally, understanding the flow rate and pressure requirements of your system can guide you in choosing the right type of valve. Knowing whether your application involves hydraulic or pneumatic systems can further influence this decision. By familiarizing yourself with these key aspects, you can ensure that you select the most suitable pilot operated check valve to meet your industrial needs efficiently.

Pilot operated check valves (POCVs) are crucial components in hydraulic systems, offering significant advantages over traditional check valves. One of the most notable benefits is their ability to prevent backflow while allowing for controlled flow during operation. According to a report by Research and Markets, the hydraulic valve market is projected to reach $12.9 billion by 2026, with pilot operated check valves accounting for a substantial portion of this growth due to their efficiency and reliability.

These valves enhance system performance by reducing pressure drops and minimizing energy loss. A study conducted by the National Fluid Power Association (NFPA) indicates that incorporating POCVs can improve hydraulic system efficiency by approximately 20-30%, making them a cost-effective choice for industries such as manufacturing, construction, and agriculture. Furthermore, POCVs can easily integrate into existing systems, providing a straightforward solution for upgrading hydraulic performance while ensuring safety and operational integrity. As industries strive for sustainability and reduced operational costs, the role of pilot operated check valves becomes increasingly vital.

When selecting a pilot operated check valve for industrial applications, it's crucial to evaluate key performance metrics such as flow rate and pressure ratings. According to a report by the Fluid Control Systems Journal, an optimal flow rate is pivotal in maintaining system efficiency, and valves should ideally support a flow rate compatible with the specific demands of your operation—often in the range of 100 GPM to 600 GPM for standard industrial settings. Additionally, understanding the pressure rating is essential; many valves are rated between 150 psi and 350 psi, which affects their suitability for high-pressure applications.

When selecting a pilot operated check valve for industrial applications, it's crucial to evaluate key performance metrics such as flow rate and pressure ratings. According to a report by the Fluid Control Systems Journal, an optimal flow rate is pivotal in maintaining system efficiency, and valves should ideally support a flow rate compatible with the specific demands of your operation—often in the range of 100 GPM to 600 GPM for standard industrial settings. Additionally, understanding the pressure rating is essential; many valves are rated between 150 psi and 350 psi, which affects their suitability for high-pressure applications.

Tip 1: Always match the valve's flow rate with your system's requirements to prevent performance bottlenecks. A valve with inadequate flow capacity can lead to excessive pressure drops, causing further complications downstream.

Tip 2: Pay close attention to the maximum pressure rating. Selecting a valve with insufficient pressure tolerance can compromise system integrity and lead to costly repairs. Industry experts recommend conducting thorough pressure tolerance tests to ensure operational safety and efficiency under varying conditions.

When choosing a pilot operated check valve, understanding the factors that influence its longevity and maintenance is crucial. The durability of these valves is often tied to the materials used in their construction and the operating conditions they endure. For instance, valves exposed to corrosive environments or fluctuating pressures may require special materials or coatings to resist wear and tear. Regular inspections and timely maintenance can significantly extend the functional life of these valves, ensuring they operate optimally under varying industrial demands.

Moreover, just as in mitral valve surgeries, where repair rates can vary dramatically based on surgical volume and expertise, the performance of pilot operated check valves can similarly depend on the manufacturer's reliability and the installation's adherence to best practices. A thorough evaluation of the valve's design and the specific application it will serve is essential. It's critical to establish a maintenance schedule that includes routine checks to identify potential issues before they lead to failures, allowing for a more reliable and cost-effective operation over time. Your choice in check valve can significantly impact your system's efficiency and safety, making informed decision-making a priority.

| Tip | Factors to Consider | Impact on Longevity | Maintenance Requirements |

|---|---|---|---|

| 1. Understand Service Conditions | Pressure and Temperature Range | Proper limits prevent early failure | Regular checks on operational conditions |

| 2. Select the Right Material | Corrosion Resistance, Temperature Tolerance | Material fatigue can shorten lifespan | Inspection for wear and tear |

| 3. Check Flow Direction | Correct installation is crucial | Reversing flow can damage valve | Monitor for unusual sounds |

| 4. Evaluate Size Requirements | Connection Size and Flow Rate | Correct sizing maximizes efficiency | Clean filters and expand checks |

| 5. Consider Back Pressure | System Design and Requirements | Influences valve opening and closing | Daily evaluation of pressure levels |

| 6. Research Actuation Methods | Pilot Pressure Types and Sources | Direct impact on valve response | Regularly assess actuation performance |

| 7. Focus on Installation Quality | Alignment and Support | Improper installation leads to failure | Post-installation inspection |

Pilot operated check valves (POCVs) are gaining traction in industrial manufacturing due to their ability to provide reliable flow control and enhance safety mechanisms. One notable case study involves a leading automotive manufacturer that experienced frequent downtime due to hydraulic system failures. By integrating POCVs into their hydraulic circuits, they achieved a significant reduction in equipment malfunctions. The POCVs allowed for controlled flow regardless of pressure fluctuations, resulting in more stable operations and shorter production lead times.

Pilot operated check valves (POCVs) are gaining traction in industrial manufacturing due to their ability to provide reliable flow control and enhance safety mechanisms. One notable case study involves a leading automotive manufacturer that experienced frequent downtime due to hydraulic system failures. By integrating POCVs into their hydraulic circuits, they achieved a significant reduction in equipment malfunctions. The POCVs allowed for controlled flow regardless of pressure fluctuations, resulting in more stable operations and shorter production lead times.

Another compelling example can be found in a chemical processing plant that faced challenges with fluid backflow and system pressure spikes. The installation of pilot operated check valves not only mitigated these issues but also improved energy efficiency across the system. By maintaining appropriate flow rates and preventing backpressure, the facility reported lower operational costs and enhanced equipment lifespan. These case studies illustrate that the strategic implementation of POCVs can lead to improved overall system performance and substantial cost savings in various industrial applications.