Leave Your Message

In the rapidly evolving landscape of industrial automation, Throttled Logic Element Valves play a crucial role in enhancing the efficiency and precision of fluid control systems. According to a recent industry report published by MarketsandMarkets, the global market for industrial valves is projected to reach $85 billion by 2025, driven by the increasing need for automation across various sectors such as oil and gas, water and wastewater management, and manufacturing. Throttled Logic Element Valves, known for their ability to regulate flow rates and pressures with a high degree of accuracy, stand out due to their unique design and functionality.

These valves are integral in applications that demand precise control over fluid dynamics, thereby optimizing operational performance and reliability in complex systems. The versatility of Throttled Logic Element Valves enables their deployment in a wide range of environments, from hydraulic circuits to pneumatic systems, ensuring that industries can maintain optimal performance under varying operational conditions. As organizations increasingly prioritize sustainability and efficiency, the adoption of advanced engineering solutions like Throttled Logic Element Valves is expected to rise, underscoring their importance in modern industrial practices. This article aims to explore the top ten throttled logic element valves, highlighting their key features, applications, and the pivotal role they play in the contemporary valve market.

Throttled Logic Element Valves play a crucial role in various industrial applications by effectively controlling the flow and pressure of fluids. These valves are designed to maintain a specific set of conditions, allowing for greater efficiency and reliability in systems. By using throttling mechanisms, they can reduce fluid speed, manage flow rates, and ensure that systems operate smoothly under varying conditions. Their significance lies in their ability to enhance performance in processes ranging from manufacturing to automotive systems, directly impacting productivity and safety.

When utilizing Throttled Logic Element Valves, it’s essential to understand their key features to maximize effectiveness. Look for valves that offer precision control, easy maintenance, and compatibility with various fluid types. Additionally, consider the specific requirements of your application, such as pressure ratings and environmental conditions, to choose the best valve for your needs.

Tips: Always ensure that the valves are regularly inspected and maintained to prevent potential issues that could disrupt system operations. Utilizing flow simulations can also help in determining the ideal valve settings before implementation, allowing for a smoother integration into existing systems.

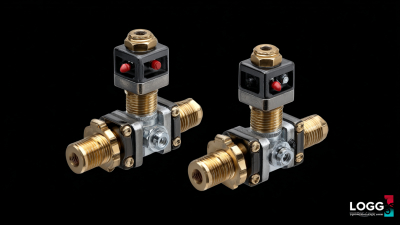

Throttled logic element valves play a crucial role in various industrial applications, primarily due to their ability to control flow and pressure with precision. When considering the key features of these valves, one must focus on their responsiveness and adjustability. A well-designed throttled logic element valve should provide seamless control over the fluid's flow rate, allowing operators to set specific conditions tailored to their system requirements. This adaptability is essential in applications ranging from hydraulic systems to pneumatic controls, where varying operational conditions exist.

Another vital aspect to consider is the valve's durability and maintenance requirements. High-quality throttled logic element valves are typically constructed from robust materials that withstand harsh environments and frequent use. Additionally, features such as ease of maintenance and the availability of replaceable components can significantly reduce downtime in industrial settings. Efficient design not only enhances longevity but also ensures that the valve continues to function optimally over time, making it a critical investment for any operation relying on precise flow management.

Throttled logic element valves play a crucial role in various industries, optimizing fluid dynamics and enhancing system efficiency. These valves are particularly significant in applications like aerospace, automotive, and manufacturing, where precise flow control is essential. According to a recent market report from Transparency Market Research, the global demand for throttled valves is projected to grow at a CAGR of 5.6% through 2028, driven by advancements in automation and process control technologies.

In the aerospace sector, throttled logic element valves are integral for hydraulic systems, helping to manage fluid flow in critical applications such as landing gear and flight control systems. The ability to maintain consistent pressure levels ensures safety and performance. Similarly, in the automotive industry, these valves assist in optimizing engine performance by regulating fuel and coolant flows, thereby enhancing fuel efficiency and reducing emissions.

Tips: When selecting a throttled logic element valve, consider the specific fluid type and pressure requirements of your system. Additionally, ensure compatibility with existing components to maximize performance and reliability. Regular maintenance and monitoring are also essential to prevent potential failures and extend the lifespan of the valve in varied operational conditions. This proactive approach can significantly reduce downtime and improve overall system efficiency.

| Valve Type | Key Features | Applications | Industries |

|---|---|---|---|

| Directional Control Valve | Precision flow control, Compact design | Automated machinery | Manufacturing, Robotics |

| Pressure Control Valve | Maintains set pressure, High accuracy | Hydraulic systems | Construction, Automotive |

| Flow Control Valve | Variable flow rates, Low leakage | Fluid management | Oil & Gas, Water treatment |

| Pneumatic Control Valve | Fast response time, Durable construction | Airflow regulation | Aerospace, Manufacturing |

| Solenoid Valve | Electromechanical operation, Low power consumption | Automated control systems | Food processing, Pharmaceuticals |

| Check Valve | Prevents backflow, Simple design | Fluid systems | Chemical, Water utilities |

| Ball Valve | High flow capacity, Reliable sealing | On-off control | Oil & Gas, HVAC |

| Globe Valve | Flow regulation, Good throttling | Flow adjustment | Power generation, Water treatment |

| Safety Shut-off Valve | Emergency shut-off, Robust design | Emergency situations | Energy, Utilities |

| Throttle Valve | Precise flow control, Adjustable | Flow regulation | Chemical processing, Manufacturing |

In the realm of fluid control systems, throttled logic element valves play a crucial role in regulating flow and ensuring the desired pressure conditions are met. This comparative analysis focuses on the top ten throttled logic element valves, highlighting essential features such as flow rate capacity, pressure rating, and materials of construction. Each valve in this selection is evaluated for its efficiency in varying applications, from industrial automation to hydraulic circuits. The valves differ in design complexity, with some featuring advanced feedback mechanisms that enhance their performance under dynamic conditions.

The applications of throttled logic element valves are diverse, ranging from precise flow control in manufacturing processes to safety systems in hydraulic power units. While analyzing these valves, critical performance metrics such as response time and reliability under extreme conditions were considered. Understanding the nuances between each option allows for better decision-making in selecting the right valve for specific application needs, ensuring operational efficiency and safety. By focusing on technical specifications and performance indicators, this analysis provides valuable insights into the capabilities and limitations of each valve type in modern engineering contexts.

The landscape of throttled logic element valve technology is rapidly evolving, driven by advancements in automation and control systems. Future trends indicate a shift toward smart-valve technologies that incorporate sensors and data analytics, enabling real-time monitoring and adjustments for optimized performance. As industries embrace the Internet of Things (IoT), these valves are expected to integrate seamlessly into digital ecosystems, facilitating better energy management and reducing operational costs.

Additionally, the development of materials and manufacturing techniques is set to enhance the durability and functionality of throttled valves. Innovations such as additive manufacturing and composite materials enable the production of lightweight yet robust components, allowing for more compact designs. This is particularly beneficial in industries such as aerospace and automotive, where space and weight are critical constraints. As environmental regulations become more stringent, the push for eco-friendly valve solutions that minimize waste and emissions will likely gain momentum, leading to a new era of sustainability in valve technology.