Leave Your Message

In the rapidly evolving landscape of automation systems, the adoption of advanced fluid control technologies is paramount. Throttled Logic Element Valves have emerged as a pivotal solution, enabling precise regulation of fluid flow with enhanced efficiency. According to a recent report by MarketsandMarkets, the global fluid control systems market is projected to reach USD 35.8 billion by 2025, growing at a CAGR of 4.5%. This growth is largely fueled by the increasing demand for automation across various industries, including manufacturing and chemicals, where the need for reliable and effective fluid management is critical. Throttled Logic Element Valves facilitate improved process control and energy efficiency, making them an essential component in modern automation frameworks. By integrating these innovative valves, businesses can not only achieve operational excellence but also contribute to sustainable practices in fluid management.

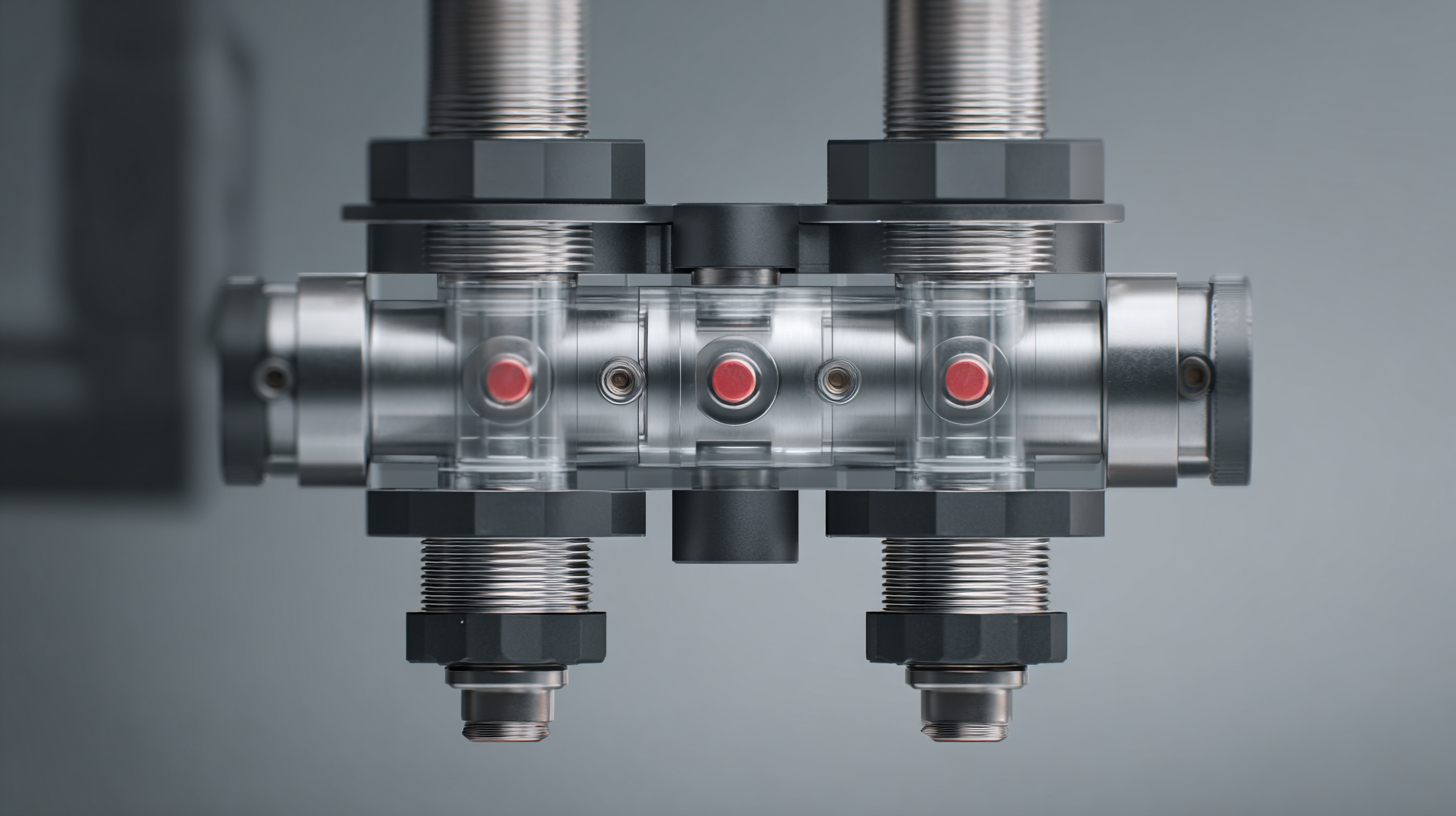

Throttled Logic Element Valves (TLEVs) represent a transformative advancement in fluid control within automation systems. Understanding how these valves operate is crucial for optimizing performance in various applications. Essentially, TLEVs provide a means to manage the flow of fluids by adjusting their resistance based on the system's requirements. They operate on principles akin to electronic components, facilitating accurate flow regulation while responding dynamically to changing conditions.

When implementing TLEVs in an automation system, it’s important to keep a few tips in mind. First, ensure that the selected valve is compatible with the system's pressure and flow requirements. Mismatched components can lead to inefficiencies or even system failures. Additionally, regular maintenance is essential to prevent clogging and ensure consistent performance. Implementing a routine inspection schedule can significantly enhance the longevity and reliability of TLEVs.

Moreover, consider using TLEVs in conjunction with sensors and control algorithms to further enhance their functionality. This integration can lead to more responsive and efficient fluid control, ultimately driving the performance of automation systems to new heights. Employing these strategies can maximize the benefits that throttled logic element valves bring to fluid management.

Throttled Logic Element Valves are rapidly changing the landscape of fluid control in automation systems. These valves offer remarkable efficiency improvements that can significantly enhance operational performance. According to a report from MarketsandMarkets, the global automation market is projected to grow from $175 billion in 2022 to over $260 billion by 2027, indicating an increasing reliance on advanced technologies such as throttled logic elements. The precision these valves provide in modulating fluid flow allows for more responsive and adaptable systems, which is critical in industries like manufacturing, pharmaceuticals, and energy.

One of the key benefits of implementing Throttled Logic Element Valves is their ability to reduce energy consumption and operational costs. A study by the International Society of Automation highlights that companies can achieve up to a 25% reduction in energy costs by optimizing fluid control through these valves. Their integrated design reduces the complexity of piping systems, further minimizing maintenance needs and downtime. Businesses equipped with these valves can expect improved reliability and longevity of their automation systems, leading to considerable savings and enhanced productivity.

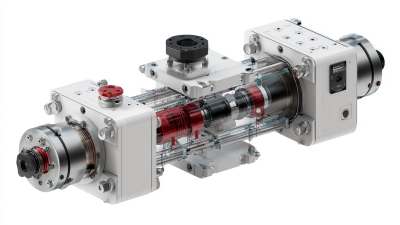

Throttled Logic Element Valves (TLEVs) are poised to outperform traditional valve systems in terms of efficiency and precision in fluid control, particularly within the context of automation systems. Unlike conventional valves that merely act as on/off switches, TLEVs utilize microfluidic technology to dynamically regulate fluid flow based on real-time requirements. This capability is essential in modern applications, where rapid adjustments are necessary to accommodate varying operational demands. Research indicates that the adoption of TLEVs can enhance process efficiency by up to 30%, significantly reducing energy consumption and material waste in automated processes.

The comparative advantages of TLEVs also extend to their integration with advanced digital systems. For instance, the development of integrated digital microfluidic systems supports a more intricate approach to fluid management, allowing for capabilities such as variable zoom in optical applications. This is exemplified in products designed to emulate natural systems, like bionic compound eyes, which rely on precise fluid control to function effectively. As industries increasingly adopt service-dominant logic, understanding the implications of this shift towards TLEVs becomes critical. Furthermore, according to recent studies, companies that incorporate such innovative technologies are likely to see a revival in their market presence, facilitated by the dual advantages of automation and improved consumer responsiveness.

| Feature | Throttled Logic Element Valves | Traditional Valves |

|---|---|---|

| Control Precision | High | Moderate |

| Response Time | Fast | Slow |

| Energy Efficiency | High | Low |

| Maintenance | Low | High |

| Cost | Higher Initial Investment | Lower Initial Cost |

| Application Range | Broad Range | Limited to Specific Applications |

Integrating throttled logic element valves into existing automation systems requires a strategic approach to ensure optimal performance and efficiency. One best practice is to conduct a comprehensive evaluation of the current system's architecture before implementation. This assessment should identify the specific fluid control needs and potential bottlenecks that throttled valves can address. Understanding the flow characteristics and process dynamics is crucial, as it will inform the selection of the appropriate valve specifications and configurations, ultimately leading to smoother operations.

Another key consideration is the training of personnel involved in the system's operation and maintenance. Familiarizing staff with the new throttled logic element valves enhances their ability to troubleshoot issues and optimize performance. Additionally, ensuring that the valves are seamlessly integrated with existing control systems can improve responsiveness and accuracy in fluid management. This might involve updating control algorithms to accommodate the unique response characteristics of throttled valves, thereby achieving enhanced process control and increased overall efficiency.

Throttled Logic Element (TLE) technology is at the forefront of transforming fluid control in automation systems. As industries look for smarter and more efficient ways to manage fluid dynamics, TLE valves are proving to be game-changers. These valves achieve precise flow control through a combination of logic elements and throttling mechanisms, allowing automation systems to respond dynamically to varying operational demands. This advancement is particularly significant as industries seek to improve productivity while simultaneously reducing energy consumption and minimizing waste.

Looking ahead, the future of fluid control will likely see even greater integration of TLE technology with IoT and artificial intelligence. This convergence will empower businesses to leverage real-time data for more informed decision-making processes. Predictive analytics can enhance the performance of automation systems, allowing for preemptive maintenance and optimization of operational parameters. As companies continue to embrace automation, the role of throttled logic element technology will be pivotal in ensuring reliability, efficiency, and sustainability in fluid management, making it an essential focus for future innovations in industrial automation.