Leave Your Message

Understanding the nuances of a Remote Control Relief Valve is essential for optimal performance. These valves play a significant role in regulating pressure within a system. They ensure safety and efficiency in various applications, from industrial settings to automotive systems.

Regular maintenance is key to achieving maximum effectiveness. Inspect the valve regularly for signs of wear or damage. Even small issues can lead to significant consequences. Ignoring these can disrupt system functionality.

Proper installation is also critical. Incorrect placement may hinder a Remote Control Relief Valve’s performance. Knowledge of the specific application is necessary. Even a minor oversight can lead to inefficiencies. Reflecting on these aspects will help enhance overall operational reliability.

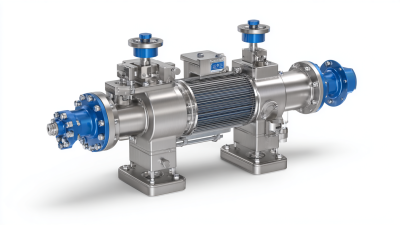

Remote control relief valves play a crucial role in hydraulic systems. They regulate pressure and ensure safety. Understanding how they function is essential for effective operation. These valves are engineered to open at predetermined pressure levels. This action prevents system overload and potential damage. Familiarity with their design aids in better control.

Here are a few tips for optimal performance. Regular maintenance is key. Check for leaks and blockages frequently. This simple task can save time and cost in the long run. Testing the response time of your valve is also beneficial. If the valve is slow to respond, it might need adjustment or replacement.

Additionally, proper installation is vital. Ensure that the valve aligns with your system's specifications. An incorrect fitting can lead to inefficiency. Not paying attention here can result in significant operational issues. Remember, understanding the basics of remote control relief valves is imperative to maximize their efficiency.

Remote control relief valves are essential in maintaining system pressure. Understanding their key components enhances performance. The actuator is crucial. It converts electrical signals into mechanical actions. Often, it requires regular calibration. Neglecting this can lead to response delays.

Next, the relief valve seat ensures proper sealing. A worn seat causes leaks, affecting pressure regulation. Regular inspections can prevent this issue. Additionally, the spring within the valve controls the opening pressure. Selecting the right spring is often overlooked. If it’s too weak, the valve opens too early. If it's too strong, it may never open.

The control signal path is another vital component. Any obstruction can lead to system failures. It's essential to keep this area clear. Maintenance often focuses on visible components, leaving beneath the surface. Regular checks on the entire system are necessary for optimal performance. Neglecting one part can lead to significant issues.

| Component | Function | Optimal Maintenance Tips | Common Issues |

|---|---|---|---|

| Pilot Valve | Controls the main valve operation based on system pressure | Regularly check for pressure consistency and clean as needed | Sticking or sluggish operation |

| Adjustable Spring | Sets the opening pressure for the relief valve | Ensure pre-load settings are correct and check for wear | Loss of spring tension or incorrect settings |

| Body Material | Constructs the valve housing and contains internal components | Inspect for corrosion and physical damage regularly | Cracks or leaks from corrosion |

| Seals and O-Rings | Prevent leakage and maintain pressure integrity | Replace regularly and check for wear after high usage | Leakage due to deteriorated seals |

| Actuator | Provides the mechanical force to open or close the valve | Lubricate regularly and test for responsiveness | Slow or unresponsive operation |

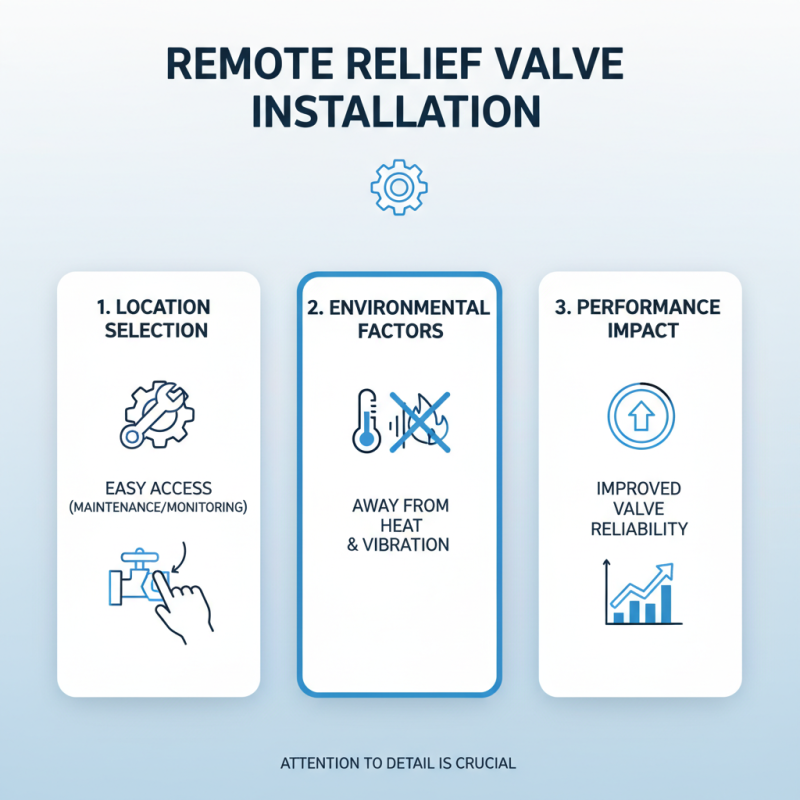

When installing a remote control relief valve, attention to detail is essential. Begin with choosing a suitable location. Ensure easy access for maintenance and monitoring. Place the valve away from heat sources and vibrations. This simple decision can influence valve performance significantly.

Proper setup is equally important. Follow installation guidelines closely. Utilize the right fittings and seals to prevent leaks. Incorrect fittings can lead to system failure or inefficiency. After installation, adjust the settings carefully. Test the operation under normal conditions. It may take time to refine adjustments for optimal functioning.

Don’t overlook regular inspections. Over time, wear and tear can affect performance. Look for signs of corrosion or obstruction. Address any issues promptly to maintain reliability. Sometimes, it’s easy to miss small details. Even minor concerns can lead to larger problems later. Make a habit of routinely checking your equipment to ensure longevity and efficiency.

Remote control relief valves are crucial for system stability. However, many users face common issues that can hinder performance. One significant problem is improper calibration. According to industry reports, 35% of system failures stem from miscalibrated valves. This often leads to over-pressurization and potential damage.

Regular maintenance is critical. Check for leaks, corrosion, and any mechanical wear. Replace worn parts promptly to avoid bigger issues. An interesting fact is that valves that receive regular maintenance can last up to 20% longer.

Tips for optimal performance include keeping the valve clean. Dirt can cause blockage and reduced efficiency. Additionally, ensure the actuator responds correctly. A faulty actuator can distort pressure readings. Test your system routinely to catch problems early.

Monitoring temperature can also help; excessive heat negatively impacts valve functionality. By addressing these common issues and applying these tips, users can significantly improve valve performance and extend equipment lifespan.

Remote control relief valves require attention for peak performance. Regular maintenance helps avoid costly repairs and ensures longevity.

Inspect the valve frequently. Look for signs of wear or corrosion. Replace any damaged parts promptly. A visual check can uncover minor issues before they escalate. Clean the valve regularly to prevent buildup. Dirt and debris can lead to malfunction.

Lubricate moving components as needed. Use the recommended type of lubricant to avoid complications. Too much or too little can disrupt performance. Pay close attention to the seals. They should be intact and functioning properly. Leaky seals can lead to inefficiency and higher costs.

Keep records of maintenance activities. This habit can highlight patterns or repeated issues. Tracking your maintenance can aid in future decisions. Remember, these valves are critical in systems. Their reliability impacts overall operation.