Leave Your Message

In the realm of hydraulic systems, ensuring optimal performance and reliability is vital for various industrial applications. Among the critical components that contribute to this efficiency is the Pressure Compensated Priority Valve. According to a report by the National Fluid Power Association, implementing advanced hydraulic solutions, including pressure compensated valves, can increase system efficiency by up to 30%. These valves play an essential role in prioritizing hydraulic flow to critical functions, thereby preventing system overload and allowing for smoother operation under fluctuating load conditions.

With the increasing demand for higher productivity and energy efficiency in industries such as construction, agriculture, and manufacturing, understanding the functionality and benefits of Pressure Compensated Priority Valves becomes imperative for engineers and technicians alike. As we delve into the specifics of these vital components, we will uncover how they enhance system performance while reducing energy consumption and wear on hydraulic systems.

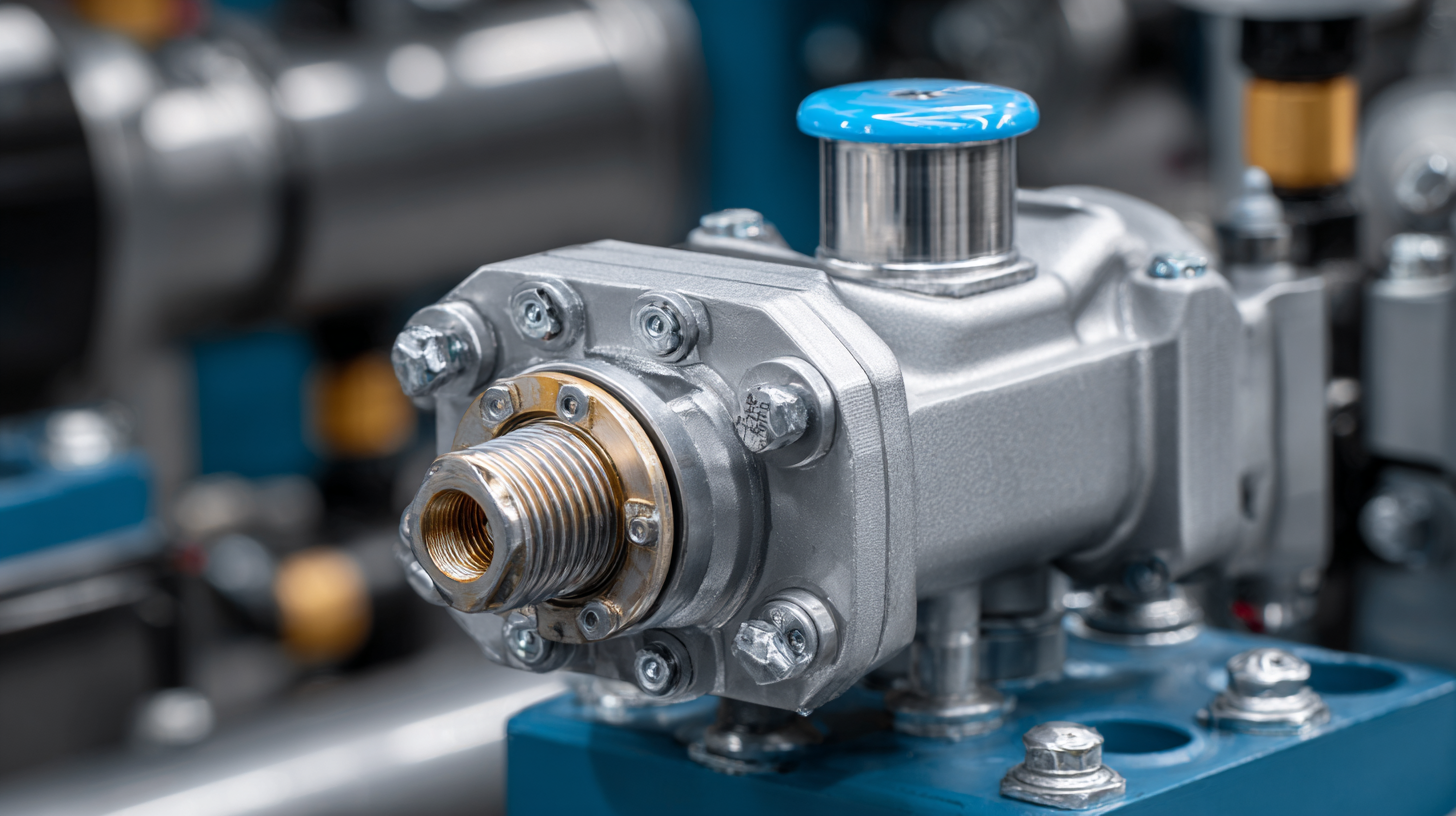

Pressure compensated priority valves are crucial components in hydraulic systems, designed to manage flow and pressure effectively. These valves ensure that primary functions receive adequate hydraulic fluid, even under varying load conditions. By maintaining a consistent pressure differential, they allow secondary functions to operate efficiently without compromising the main application's performance. This is particularly important in systems where multiple actuators depend on the same hydraulic supply.

The operation of pressure compensated priority valves relies on a sensing mechanism that adjusts the flow according to the demand of the primary circuit. When the pressure in the primary circuit drops, the valve compensates by altering its opening, which helps maintain the necessary flow rate. This adaptability is what makes these valves essential for dynamic hydraulic operations, where conditions frequently change.

Ultimately, understanding the principles behind pressure compensated priority valves not only enhances the efficiency of hydraulic systems but also optimizes their overall reliability.

Pressure compensated priority valves play a crucial role in hydraulic systems by ensuring that the hydraulic pressure is maintained at optimal levels, even under varying load conditions. This pressure compensation is essential for managing the efficiency and responsiveness of hydraulic actuators. For instance, recent advancements in hydraulic system designs for mobile applications highlight the importance of balancing pressure and flow dynamically, allowing for improved performance in tasks ranging from loader cranes to automated robotic systems. According to industry reports, systems utilizing pressure compensated valves can reduce energy consumption by up to 30%, showcasing their significance in energy-efficient hydraulic applications.

Moreover, the integration of advanced control strategies, such as adaptive neural controllers combined with pressure compensated systems, can enhance overall system performance further. For instance, studies indicate that employing these technologies in injection molding machines leads to more precise control and quicker response times, directly influencing productivity metrics. As electro-hydraulic solutions continue to redefine functionality and efficiency across various sectors, understanding the pivotal role of pressure compensation is fundamental for engineers and operators striving to optimize hydraulic system designs.

This chart illustrates the key functions of pressure compensated priority valves in hydraulic systems. The data highlights four critical metrics: flow rate, pressure, efficiency, and response time, which are essential for understanding the performance and effectiveness of these valves in hydraulic applications.

Pressure compensated priority valves play a crucial role in enhancing hydraulic system performance, particularly in machinery like excavators. These valves ensure that essential functions receive priority hydraulic flow, allowing operators to control multiple functions simultaneously without sacrificing efficiency. By delivering a consistent flow to critical components, pressure compensated priority valves minimize the risk of power loss and equipment strain, which is especially beneficial in demanding environments.

The recent introduction of new excavator models highlights the growing need for advanced hydraulic systems that can manage increasing operational demands. The integration of priority valves in these machines enables optimal performance by ensuring that vital operations, such as arm movement and excavation, have the necessary hydraulic support without compromising other functions. This results in improved efficiency, better fuel economy, and enhanced overall productivity, demonstrating the advantages of incorporating pressure compensated priority valves in modern hydraulic machinery.

Installing pressure compensated priority valves in hydraulic systems is a critical task that can significantly enhance the performance and efficiency of the system. To successfully install these valves, start by ensuring you have all the necessary tools and components ready. Familiarize yourself with the schematic of your hydraulic system to locate the appropriate mounting positions for the valves. A clean work environment is essential to prevent contamination, which can adversely affect the system's functionality.

Once you have identified the correct placement, carefully mount the priority valves following the manufacturer's specifications. Make sure to connect the hydraulic lines securely to avoid leaks. After the installation, it's important to test the system under various load conditions to ensure proper operation.

Monitor the pressure readings throughout this process to confirm that the valves are compensating for fluctuations effectively. By following these steps, you can ensure your hydraulic system operates smoothly and efficiently with the added benefits of pressure compensated priority valves.

Pressure compensated priority valves are crucial in hydraulic systems, ensuring that priority circuits receive appropriate flow while allowing non-priority circuits to function without compromising performance. Despite their reliability, these valves can face operational issues that impact system efficiency. Common problems include erratic flow, pressure drops, and response delays, which can often be traced back to contamination, incorrect adjustment, or wear and tear.

When troubleshooting these valves, the first step is to check for fluid contamination, as foreign particles can obstruct flow paths. Industry reports indicate that up to 70% of hydraulic system failures can be attributed to dirty fluids. Regular fluid analysis and filtration maintenance are vital in preventing this issue. Additionally, ensuring that the valve is correctly set for the specific application is essential; improper adjustments may result in inadequate pressure compensation, leading to inadequate system performance. Keeping an eye on operational parameters and conducting routine inspections can help in identifying early signs of wear and prevent catastrophic failures.