Leave Your Message

In today's industrial landscape, ensuring optimal performance of systems that utilize hydraulic and pneumatic mechanisms is paramount. Pilot Operated Relief Valves (PORVs) play a crucial role in maintaining system integrity and preventing overpressure situations. According to a report from the International Society for Automation, nearly 30% of industrial downtime is attributed to equipment failures related to pressure control, highlighting the importance of effective relief solutions. Moreover, the global relief valve market is projected to grow significantly, reaching USD 7.4 billion by 2026, as industries increasingly recognize the vital function of technologies like PORVs in enhancing operational safety and efficiency. By implementing a comprehensive checklist approach to optimize the performance of Pilot Operated Relief Valves, organizations can mitigate risks and enhance reliability, ensuring that their processes run smoothly and safely.

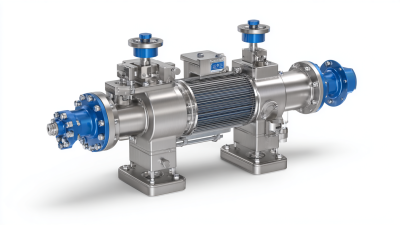

Pilot operated relief valves (PORVs) are critical components in hydraulic systems, designed to ensure safety and regulate pressure effectively. Understanding their basics and benefits can significantly enhance operational efficiency. According to the National Fluid Power Association, proper pressure control mechanisms can improve system reliability by up to 30%, preventing unexpected downtimes and system failures.

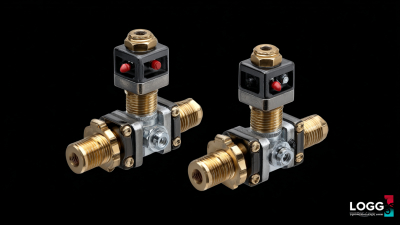

One of the primary advantages of PORVs is their ability to handle high flow rates while maintaining precise pressure regulation. They utilize a small pilot valve to control a larger main valve, which allows for a more responsive and efficient operation. This feature not only minimizes energy consumption but also contributes to safety by preventing over-pressurization. Industry data suggests that implementing advanced relief systems like PORVs can lead to energy savings of approximately 15-20%.

Tip: Regular maintenance and testing of pilot valves are essential to ensure their reliable performance. Inspecting seals and O-rings can help identify wear and avoid leaks that can compromise system integrity. Additionally, calibrating valves periodically will help in maintaining accurate pressure settings, which is vital for the stability of hydraulic systems.

When it comes to optimizing performance with pilot operated relief valves, several key factors play a critical role. Firstly, the selection of the appropriate valve size and type is paramount. A valve that is too large can lead to instability, while one that is too small may not release sufficient pressure, rendering the system inefficient. Additionally, ensuring the valve is designed for the specific application pressure and flow rates improves overall responsiveness and reliability.

Another significant factor affecting performance optimization is the quality of the installation and maintenance routines. Proper installation ensures that the valve operates at the intended pressure settings without leaks or unnecessary wear. Regular maintenance checks, including the inspection of pilot circuits and the calibration of pressure settings, can prevent malfunctions and prolong the lifespan of the valve. Moreover, attention to environmental conditions, such as temperature and corrosion factors, further supports efficient valve operation, ultimately enhancing system safety and performance.

This bar chart illustrates key factors affecting the performance optimization of pilot operated relief valves, showcasing various performance metrics on a scale from 1 to 10.

Pilot operated relief valves (PORVs) are crucial in maintaining safety and efficiency across various industrial applications. To ensure these vital components function optimally, adhering to best practices for maintenance and troubleshooting is essential. Regular inspections and testing can significantly reduce the likelihood of unplanned shutdowns; according to the 2020 Valve Industry Outlook Report, companies that implemented proactive maintenance strategies saw a 25% reduction in valve failure rates.

Proper troubleshooting begins with understanding the symptoms of various issues. Common problems like inconsistent pressure control or leakage can often be traced back to pilot system malfunctions or deposits in the pilot valve. The American Society of Mechanical Engineers (ASME) indicates that performing regular cleaning and calibration of the pilot mechanism can enhance responsiveness and accuracy, leading to improved system reliability.

Additionally, maintaining proper temperature and pressure within recommended limits is vital for prolonging the life of pilot operated valves. The National Institute of Standards and Technology (NIST) underscores the importance of routine checks to ensure compliance with operational standards, which can prevent costly accidents and maintain efficiency. By following these best practices, operators can significantly improve the reliability and performance of pilot operated relief valves in their systems.

Pilot operated relief valves (PORVs) play a crucial role in modern pressure management systems, providing advanced solutions that enhance efficiency and safety. Recent studies indicate that implementing high-performance PORVs can reduce system pressure fluctuations by up to 30%, significantly improving the overall operational reliability. According to a report by the Engineering Equipment and Materials Users Association (EEMUA), optimizing these valves can also lead to energy savings of approximately 15%, translating into considerable cost reductions for industrial operations.

One innovative solution for enhancing efficiency is the integration of advanced diagnostic tools with PORVs. Real-time monitoring systems can provide critical insights into valve performance, allowing for proactive maintenance and reducing unexpected downtime. The American Society of Mechanical Engineers (ASME) emphasizes that such predictive maintenance strategies can extend equipment lifespan by up to 25%. Additionally, employing smart technology can help operators adjust settings dynamically to match changing process conditions, further optimizing performance and ensuring compliance with safety standards while maximizing productivity.

Pilot operated relief valves are critical components in various industrial systems, providing overpressure protection and maintaining operational integrity. Recent case studies have demonstrated successful optimization of these systems, leading to significant improvements in efficiency and safety. For instance, a study conducted by the American Society of Mechanical Engineers (ASME) highlighted that optimizing pilot operated relief valves can reduce system response time by up to 30%, enhancing both operational reliability and safety margins.

In one case study, a chemical processing plant implemented sophisticated simulation software to analyze their existing pilot operated relief systems. By fine-tuning the valve sizing and selecting appropriate spring rates, the plant achieved a 15% reduction in energy costs while also minimizing the risk of system failures. Furthermore, the Engineering and Equipment Institute noted that proper maintenance and calibration of these valves can increase their lifespan by 20%, leading to considerable long-term cost savings for plant operators.

Additionally, another study from the Hydraulic Institute illustrates that integrating advanced diagnostic tools can lead to proactive maintenance strategies, reducing unexpected downtimes by nearly 40%. These findings underscore the importance of continuous improvement practices in pilot operated relief systems, as industries look to optimize performance while ensuring compliance with ever-evolving safety regulations.

| Case Study Title | Industry | Initial Issue | Optimization Solution | Results Achieved |

|---|---|---|---|---|

| Petrochemical Plant Efficiency | Petrochemical | Frequent system trips due to overpressure | Re-calibrated pilot valves and implemented regular maintenance schedule | Reduced trips by 75% and improved system reliability |

| Power Generation Safety | Energy | Inconsistent pressure readings on relief systems | Installed upgraded relief valves with enhanced sensors | Achieved 30% more accuracy in pressure readings |

| Food Processing Streamlining | Food and Beverage | High frequency of valve maintenance | Implemented automatic valve testing and tracking system | Decreased maintenance frequency by 50% |

| Chemical Processing Upgrades | Chemical | Inadequate valve response causing safety concerns | Replaced outdated pilot operated relief valves with modern equivalents | Improved response time by 40% and enhanced safety |

| Hydraulic System Performance | Manufacturing | Frequent pressure fluctuations | Calibrated pressure settings and installed surge protection | Stabilized pressure variance and increased machine uptime by 20% |