Leave Your Message

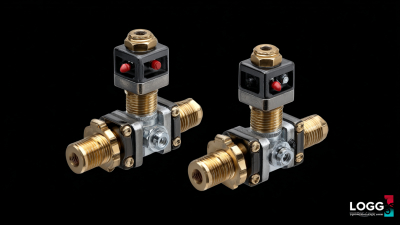

In today's competitive industrial landscape, optimizing system performance is critical for enhancing productivity and reducing operational costs. One of the key components in achieving this optimization is the integration of Directional Logic Element Valves, which play a vital role in fluid power systems. According to a recent report by the International Fluid Power Association, systems employing advanced directional control technology can improve efficiency by up to 25%, leading to significant energy savings and reduced wear on components. Moreover, the growing emphasis on sustainability and energy efficiency in manufacturing processes further underscores the importance of utilizing Directional Logic Element Valves. By strategically implementing these valves, industries can not only streamline operations but also align with global standards for environmental performance, ultimately pushing the boundaries of operational excellence.

Directional Logic Element Valves play a crucial role in optimizing systems across various industrial applications. These valves manage the flow of fluids and direct pressure, ensuring that the operation runs smoothly and efficiently. According to industry reports, the use of such valves can reduce energy consumption by up to 30%, making them an essential component for maximizing system efficiency. By precisely controlling the direction and flow of hydraulic fluids, organizations enhance their operational capabilities while minimizing waste.

Moreover, when integrated with pneumatic control mechanisms, the advantages become even more pronounced. Pneumatics offers a safe and cost-effective method to manage hydraulic systems, leading to increased reliability and performance. A study from a recent market analysis indicated that systems employing pneumatic control alongside directional logic element valves experience a 20% improvement in response time and a significant reduction in mechanical wear. As industries strive for sustainability and operational excellence, investing in these advanced control systems is pivotal for long-term success and resource optimization.

This bar chart illustrates the efficiency percentages of various Directional Logic Element Valves. Analyzing these efficiencies can help you choose the optimal valve for enhancing system performance.

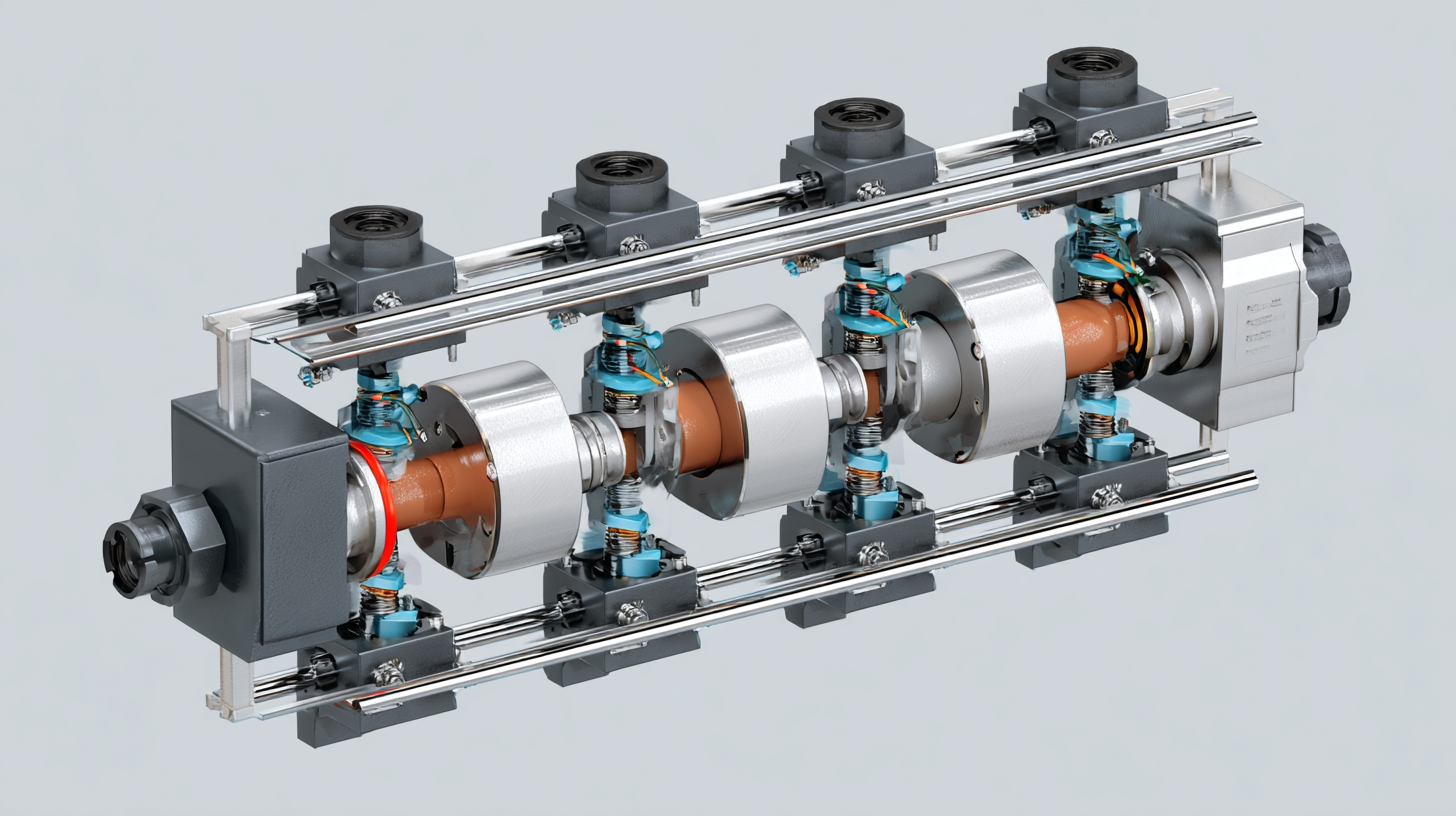

Directional Logic Element Valves are crucial for enhancing system efficiency, particularly in

off-road hydraulics where energy consumption and pollutant emissions are significant concerns. These valves optimize the flow and direction of hydraulic fluids, thereby ensuring that machines operate at peak performance levels. By implementing directional logic element valves, you can

reduce energy loss and improve the overall effectiveness of your hydraulic systems.

Directional Logic Element Valves are crucial for enhancing system efficiency, particularly in

off-road hydraulics where energy consumption and pollutant emissions are significant concerns. These valves optimize the flow and direction of hydraulic fluids, thereby ensuring that machines operate at peak performance levels. By implementing directional logic element valves, you can

reduce energy loss and improve the overall effectiveness of your hydraulic systems.

Tips: To maximize the benefits of directional logic element valves, consider integrating them into a well-structured energy management system. Regular maintenance is vital; ensure that the valves are inspected routinely to prevent leaks and inefficiencies. Additionally, training your operators on the proper usage of these valves can lead to better performance and longevity of your machinery.

Another critical aspect is the design of user-friendly interfaces that allow operators to adjust settings quickly and efficiently. This not only helps in real-time optimization but also empowers the workforce to contribute to energy-saving efforts actively. By focusing on these key areas, you can unlock the full potential of directional logic element valves and significantly enhance the efficiency of your hydraulic systems.

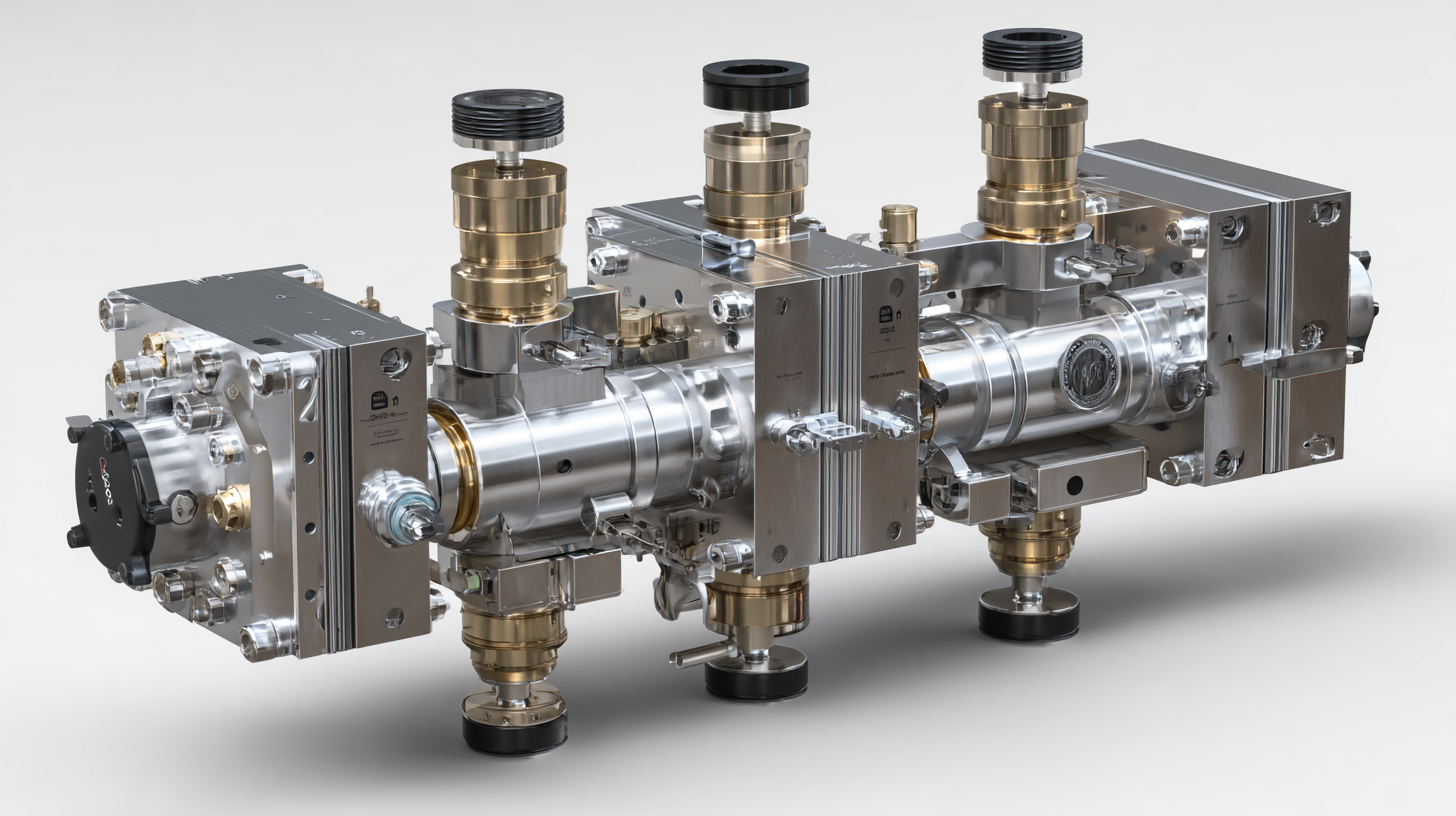

When selecting a directional logic element valve, the first step is to assess the specific requirements of your system. Consider factors such as flow rate, pressure, and the types of media your system will handle. Understanding these parameters helps in selecting a valve that aligns with the operational demands and enhances overall efficiency.

Tip: Always opt for valves that offer flexibility in configuration. Modular designs allow for easy upgrades or modifications in the future, meaning the valve can adapt to changing operational conditions without necessitating a complete system overhaul.

Additionally, evaluate the materials used in the valve construction. Choosing valves made from corrosion-resistant materials or those that can withstand extreme temperatures will significantly impact the longevity and reliability of the system.

Tip: Consult with manufacturers regarding the predicted lifespan of their products. This information can guide you in selecting a valve that not only meets your current needs but will also endure over time, thereby reducing maintenance costs.

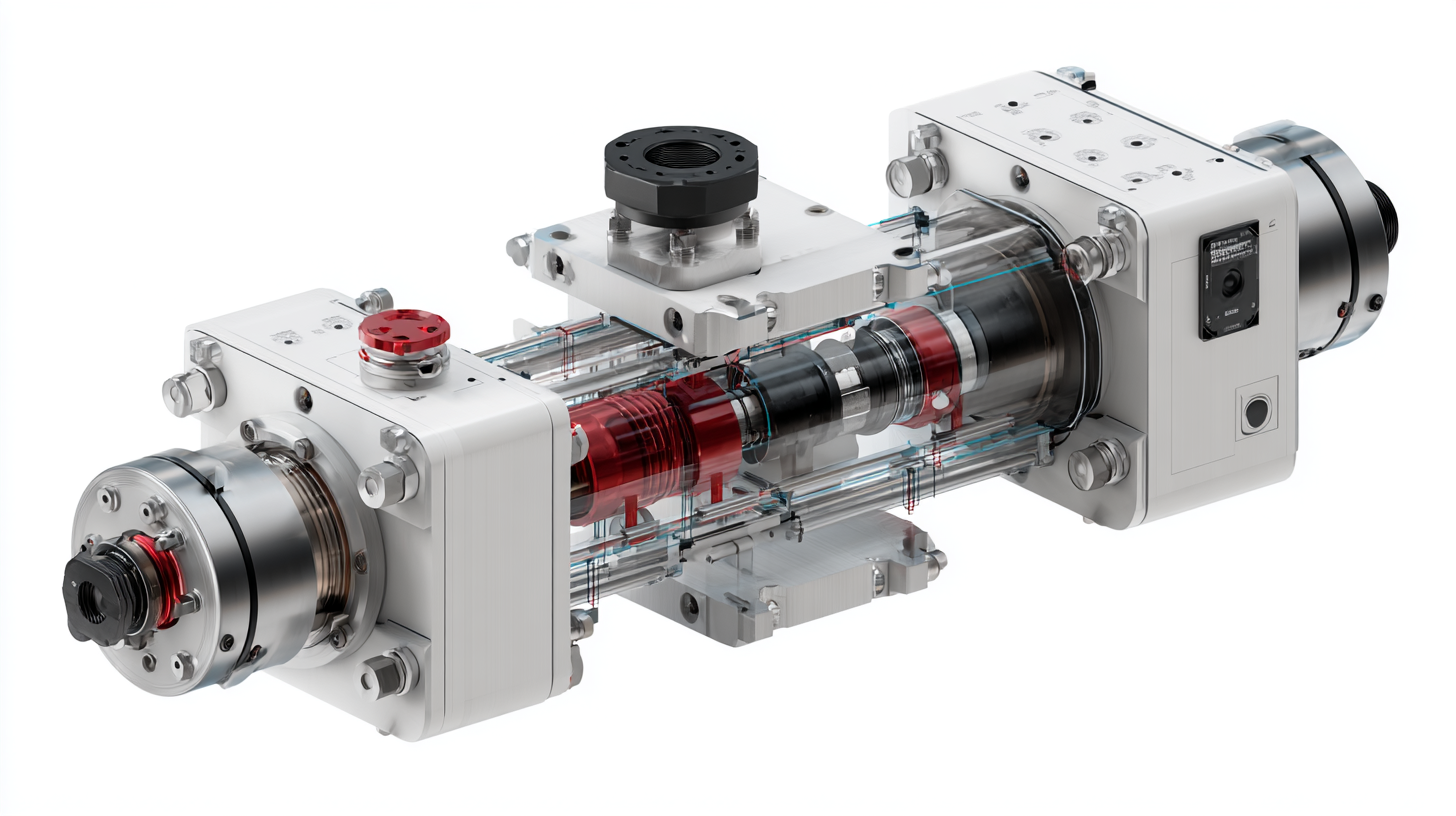

Integrating Directional Logic Element Valves into existing systems can significantly enhance operational efficiency. The first step involves a thorough assessment of your current setup to identify how these valves can fit. Start by mapping out the existing flow paths and control sequences, which will allow you to pinpoint areas where directional logic can streamline processes, reduce energy consumption, or increase throughput. Understanding the specific requirements of your system—such as pressure ratings and flow rates—is essential to determine the appropriate valve sizes and types for optimal performance.

Once you have identified the integration points, the next phase is designing a control strategy that takes full advantage of the directional logic capabilities. Implement smart sensors and controllers that can dynamically adjust valve positions based on real-time data, enhancing responsiveness and reducing manual intervention. Additionally, training staff on the new system dynamics and maintenance protocols will ensure a smooth transition. By fostering collaboration between engineering and operations teams, you can create a feedback loop that continuously optimizes the system as it adapts to the newly integrated directional logic element valves.

| Parameter | Value | Notes |

|---|---|---|

| Flow Rate (L/min) | 50 | Optimal for moderate applications |

| Pressure (bar) | 10 | Recommended working pressure |

| Temperature (°C) | 25 | Ideal for valve operation |

| Voltage (V) | 24 | Common control voltage |

| Response Time (ms) | 30 | Fast switching response |

| Life Cycle (cycles) | 1,000,000 | Durable for long-term use |

| Integration Difficulty | Medium | Requires some adjustments |

When implementing directional logic element valves, several common challenges can arise, particularly in applications requiring split-range control. One major issue is the difficulty in achieving accurate flow control due to the valve's complexity. In many cases, functional flow throttling can hinder performance, leading to inefficiencies. To address this, it’s essential to focus on optimizing the control system to enhance responsiveness and precision.

Tip: Consider using advanced positioning systems that allow for faster adjustments, reducing lag in the responsiveness of the valve. This can lead to improved overall system performance and reduced energy waste.

Another challenge lies in ensuring compatibility with existing hydraulic systems, especially in off-road applications. Many systems may not be designed to accommodate the needs of directional logic element valves, which could result in increased wear and tear or suboptimal operation. A robust analysis of existing systems can reveal potential integration issues.

Tip: Conduct a thorough assessment of the hydraulic system prior to implementation, identifying areas where enhancements can be made. Upgrading components that are susceptible to wear can significantly lengthen the lifespan of the new valves and improve efficiency.