Leave Your Message

In the realm of industrial applications, the efficiency of systems can dramatically impact operational costs and productivity. A pivotal component in achieving this efficiency is the Pressure Reducing Relief Valve (PRRV), which plays an essential role in maintaining optimal pressure levels within piping systems. According to a report by the Fluid Controls Institute, improperly managed pressure can lead to energy losses of up to 30%, significantly affecting bottom-line performance. Moreover, the use of PRRVs can enhance safety by preventing overpressure scenarios that could jeopardize equipment integrity. Industry studies indicate that effective pressure management can increase system longevity by as much as 25%, emphasizing the critical importance of these valves in process optimization. Therefore, understanding the crucial function and benefits of Pressure Reducing Relief Valves is vital for industries striving to maximize system performance and operational efficiency.

Pressure reducing relief valves (PRRVs) play a critical role in industrial applications by optimizing energy efficiency and ensuring system reliability. These valves regulate the pressure within a system, allowing for a controlled operation that minimizes energy consumption. By maintaining the pressure at desired levels, PRRVs prevent over-pressurization, which can lead to energy waste and increased operational costs. This not only enhances overall efficiency but also extends the lifespan of equipment, reducing maintenance and replacement needs.

**Tips:** Regular maintenance of pressure reducing relief valves is essential for optimal performance. Schedule routine inspections to check for wear and tear and ensure they are functioning as designed. Additionally, consider implementing a monitoring system to track pressure levels and valve performance in real-time, allowing for immediate adjustments and preventing inefficiencies.

Moreover, integrating PRRVs into your facility can lead to significant energy savings. By utilizing these valves, industries can adapt to varying loads without compromising system integrity. This flexibility not only contributes to lower energy bills but also supports sustainability efforts, making your operations greener in the long run.

Pressure reducing relief valves (PRRVs) play a critical role in optimizing system efficiency across various industrial applications. These valves are designed to manage and maintain the appropriate pressure levels within systems, preventing overpressure scenarios that could lead to equipment failure or unsafe conditions. Effective pressure management not only protects assets but also enhances productivity by ensuring systems operate within their designed parameters.

Implementing PRRVs leads to significant cost savings by minimizing energy consumption and reducing wear and tear on machinery. By maintaining optimal pressure, facilities can achieve lower operational costs, extend the lifespan of their equipment, and avoid costly downtime. Keeping pressure levels in check also ensures that products are manufactured consistently and efficiently, which can translate to higher quality and lower waste.

**Tips for Effective Pressure Management:**

- Regularly inspect and maintain your PRRVs to ensure they function correctly, preventing unexpected failures.

- Monitor the pressure levels in your systems using gauges and automation solutions, allowing for quick adjustments when necessary.

- Train staff on the importance of pressure management to foster a culture of efficiency and safety within your facility.

| Application | Pressure Reduction (%) | Cost Savings (Annual) | Energy Efficiency Improvement (%) | Environmental Impact (Reduction in Emissions) |

|---|---|---|---|---|

| Chemical Processing | 30% | $50,000 | 15% | 300 tons/year |

| Oil and Gas | 20% | $75,000 | 10% | 500 tons/year |

| Water Treatment | 25% | $20,000 | 12% | 200 tons/year |

| Power Generation | 15% | $100,000 | 20% | 600 tons/year |

Pressure reducing relief valves (PRVs) play a critical role in safeguarding the longevity of industrial systems. According to a study by the International Journal of Pressure Vessels and Piping, over 40% of industrial equipment failures can be traced back to improper pressure regulation, resulting in costly downtimes and maintenance. By maintaining optimal pressure levels, PRVs mitigate the risk of system fatigue and catastrophic failures, which can significantly reduce maintenance costs. The report highlights that facilities utilizing properly functioning PRVs can experience up to a 30% decrease in unscheduled maintenance events.

Furthermore, the economic impact of PRVs extends beyond immediate maintenance savings. The Valve Manufacturers Association (VMA) indicates that the total cost of ownership, which includes installation, maintenance, and operational costs, can be reduced by up to 20% with the use of efficient pressure reducing relief valves. Keeping systems within their designed pressure range not only prolongs the lifespan of equipment but also enhances overall operational efficiency. As industries seek to optimize their processes and reduce expenses, the integration of PRVs emerges as a fundamental component toward achieving sustainable manufacturing practices.

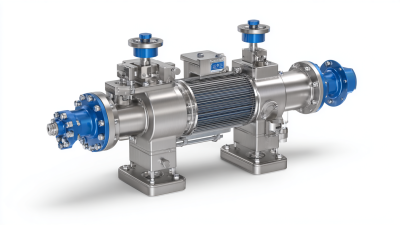

The implementation of pressure reducing relief valves (PRRVs) in various industrial applications has led to significant efficiency gains, as evidenced by numerous case studies. In the petrochemical sector, for instance, the integration of PRRVs in processing systems has been shown to minimize pressure fluctuations, thereby stabilizing operations and reducing energy consumption. Facilities that have adopted these valves reported up to a 20% decrease in operational costs through improved process reliability and reduced downtime.

The implementation of pressure reducing relief valves (PRRVs) in various industrial applications has led to significant efficiency gains, as evidenced by numerous case studies. In the petrochemical sector, for instance, the integration of PRRVs in processing systems has been shown to minimize pressure fluctuations, thereby stabilizing operations and reducing energy consumption. Facilities that have adopted these valves reported up to a 20% decrease in operational costs through improved process reliability and reduced downtime.

Similarly, in the food processing industry, PRRVs play a crucial role in maintaining precise pressure levels during production. In one case study, a dairy manufacturing plant that installed PRRVs observed enhanced product quality and a notable reduction in waste. The ability to control pressure accurately not only ensures that products meet safety standards but also contributes to a more efficient and sustainable manufacturing process. These examples illustrate how the strategic use of relief valves can transform operational efficiency across diverse industrial landscapes.

In the industrial sector, regulatory standards play a pivotal role in the implementation and functionality of pressure reducing relief valves (PRVs). These standards, established by organizations such as the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO), dictate not only the design and manufacturing processes of these valves but also their testing and operational procedures. According to a report by the American National Standards Institute (ANSI), over 70% of industrial facility failures arise from inadequate safety measures, underscoring the importance of adhering to these rigorous standards to prevent hazardous incidents.

Moreover, compliance with regulatory guidelines enhances system reliability and efficiency, ultimately affecting a company's bottom line. A study by the National Safety Council indicates that industries adhering to prescribed safety regulations see a 40% reduction in operational downtime. This highlights how PRVs, when implemented according to industry standards, not only mitigate risks associated with overpressure scenarios but also contribute to overall system performance. In the long run, companies that prioritize adherence to regulatory standards for their pressure relief systems are likely to achieve greater operational efficiency and competitiveness in the market.