Leave Your Message

Load Control Valves (LCVs) play a critical role in enhancing the efficiency and performance of hydraulic systems across various industrial applications. According to a report by the International Journal of Fluid Power, systems employing optimized LCVs can improve energy efficiency by up to 30%, significantly reducing operational costs and environmental impact. Moreover, recent findings from the Hydraulics and Pneumatics Association indicate that effective load control can lead to a 25% increase in system reliability by minimizing shock loads and pressure spikes. As industries increasingly prioritize sustainable practices and energy optimization, understanding the mechanisms and advantages that Load Control Valves provide becomes paramount. This comprehensive guide explores the functionalities of LCVs, their impact on system dynamics, and best practices to implement for achieving maximum performance and efficiency.

Load control valves play a crucial role in optimizing system performance, particularly in complex energy systems. As hybrid interconnected power systems evolve, the need for advanced control mechanisms becomes increasingly apparent. Load control valves contribute significantly to maintaining stability and efficiency, enabling precise regulation of fluid flow and energy distribution. This is particularly vital in modern applications where the integration of renewable energy sources adds layers of complexity to system operations.

In the context of emerging technologies, innovations such as mobile valves and automated control systems further enhance the efficacy of load control valves. These advancements not only improve hydraulic efficiency but also support dynamic load adjustments in response to varying demand. By utilizing intelligent control strategies, systems can effectively manage heat output and energy consumption, leading to better overall performance. As the landscape of power generation evolves, the optimization of load control valves remains a key focus for enhancing energy efficiency and sustainability.

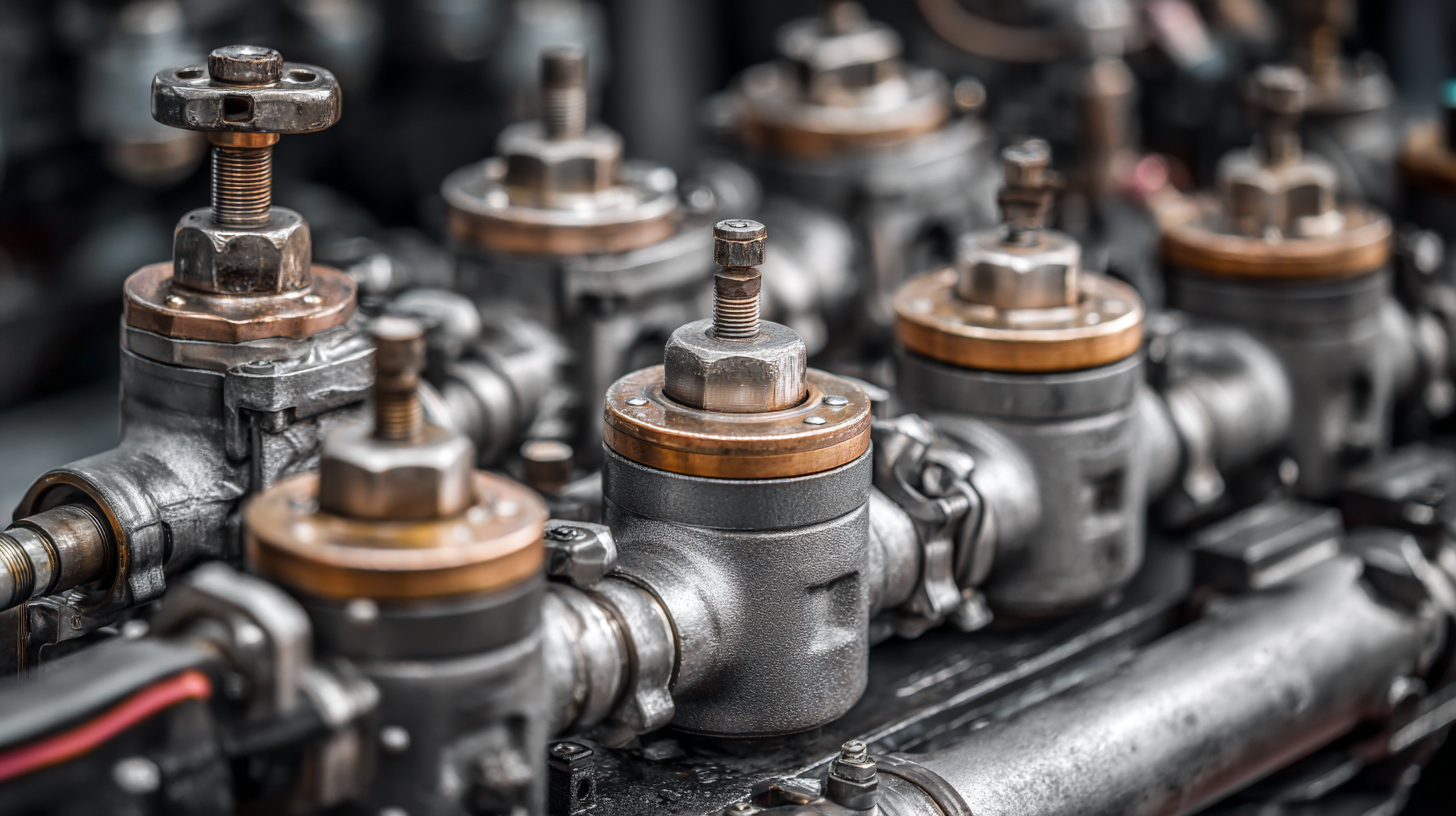

Load control valves play a crucial role in enhancing energy efficiency within hydraulic systems. By regulating the flow and pressure of fluid based on real-time demands, these valves ensure that the system operates only at the required levels. This not only minimizes energy wastage but also extends the longevity of system components. The mechanics behind load control valves involve sophisticated feedback mechanisms that adjust flow rates dynamically, aligning with varying operational conditions.

Tips: Regular maintenance of load control valves is essential. Check for leaks and ensure proper calibration to guarantee peak performance. Furthermore, consider incorporating sensors that can provide data on fluid conditions, allowing for real-time adjustments.

Tips: Implementing a monitoring system for load control valves can help track their performance and detect issues early, ensuring your system runs at optimum efficiency.

Load control valves play a crucial role in enhancing system efficiency and performance across various applications. By implementing these valves, systems can achieve dynamic balancing and efficient flow regulation, resulting in significant energy savings. For instance, hydronic systems have evolved from constant to variable volume systems, benefitting from technologies that allow for rapid response to changes in demand, thereby optimizing energy consumption and increasing overall system functionality.

Recent advancements in valve technology have focused on improving operational strategies in complex setups, such as steam turbine generators integrated with energy storage systems. By replacing traditional components with load control valves, operators can streamline processes and reduce operational costs, especially in scenarios where the system must rapidly adapt to varying load conditions. Additionally, studies highlighting the performance of motor-controlled versus valve-controlled systems indicate that load control valves can lead to more efficient energy usage, confirming their value in modern engineering solutions.

Load control valves play a vital role in enhancing system efficiency and performance across various applications. In real-world scenarios, integrating these valves can lead to significant improvements in energy consumption and operational effectiveness. For instance, a comparative study on knuckle boom crane operations evaluated the energy usage between motor-controlled and valve-controlled systems. The results highlighted that systems utilizing load control valves could optimize energy consumption while maintaining performance levels, indicating their potential to reduce overall operational costs.

Tips: When considering the integration of load control valves, assess the specific requirements of your system to determine the appropriate valve type. Regular maintenance and monitoring can further enhance the efficiency of these valves, ensuring optimal performance over time. Implementing intelligent systems alongside load control valves can also lead to better decision-making and increased adaptability to varying loads.

Furthermore, recent studies on automatic generation control (AGC) in power systems demonstrate the importance of optimizing load management under real-world variations. The integration of load control valves within power systems can potentially fortify resilience against fluctuating demands, thereby improving overall system reliability. Investing in such technologies not only enhances performance but also contributes to sustainability efforts in energy management.

Future trends in load control valve technology are poised to revolutionize the efficiency of various systems across multiple industries. One significant advancement is the integration of smart technologies, enabling real-time monitoring and adaptive responses to changing load conditions. These intelligent systems utilize data analytics and machine learning algorithms to optimize valve performance and system responsiveness, thereby reducing energy consumption and improving overall efficiency. As industries increasingly prioritize sustainability, the demand for energy-efficient load control solutions will drive further innovations in valve design and operation.

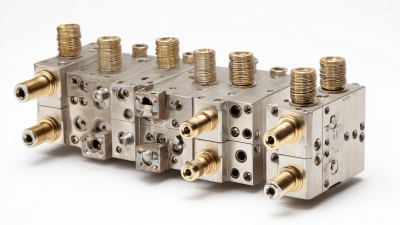

In addition to smart technologies, the move towards modular and customizable load control valve systems allows for greater flexibility and scalability. By enabling the easy integration of different components, these systems can be tailored to meet specific operational requirements, leading to enhanced performance and reduced downtimes. Furthermore, advancements in materials technology are paving the way for more durable and resilient valve designs, minimizing maintenance costs and extending lifecycle. As these trends continue to develop, they will significantly impact system optimization strategies, empowering industries to achieve heightened performance while adhering to stringent environmental standards.

This chart illustrates the impact of load control valves on system efficiency, showing a significant increase in efficiency when load control valves are utilized in the system.