Leave Your Message

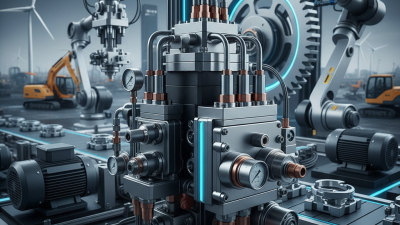

In the world of fluid control, the Hydraulic Lift Valve Manifold stands out as a crucial component that dramatically enhances operational efficiency and accuracy. Designed to manage the flow and pressure of hydraulic fluids, this manifold system enables seamless integration of multiple valves while optimizing space and functionality. By consolidating various control mechanisms into a single unit, the Hydraulic Lift Valve Manifold minimizes potential leaks and reduces the complexity often associated with conventional systems.

Moreover, the efficiency provided by the Hydraulic Lift Valve Manifold is not just about space-saving; it also plays a significant role in improving responsiveness and performance in hydraulic applications. With precise control over fluid distribution, operators can expect improved cycle times and reduced energy consumption, leading to enhanced productivity.

In this article, we will explore the indispensable features and advantages of the Hydraulic Lift Valve Manifold, offering valuable tips on how to incorporate this technology into your fluid control systems for optimal results.

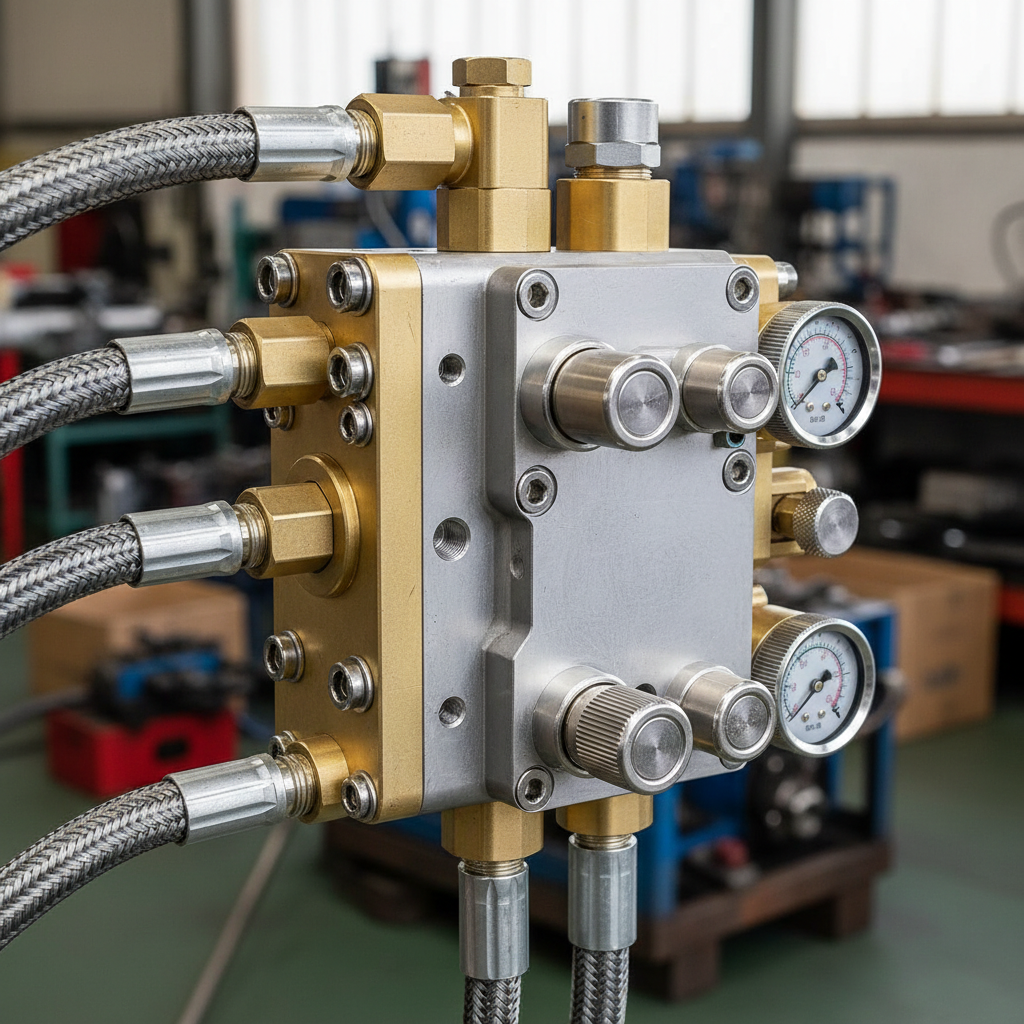

Hydraulic lift valve manifolds play a crucial role in enhancing efficiency within fluid control systems. These systems are integral to a variety of applications, particularly in subsea operations where streamline control over fluid flow is essential. By consolidating multiple hydraulic valves into a compact manifold, these systems not only reduce the complexity of piping but also minimize pressure drops and enhance responsiveness. For example, recent industry reports indicate that effective use of hydraulic manifolds can improve operation efficiency by up to 30%, which is critical in energy transition applications.

Incorporating all-electric systems aligns perfectly with the evolution of hydraulic lift valve manifold technology. Transitioning to all-electric systems enables more precise control of hydraulic functions and, simultaneously, reduces maintenance costs and environmental impact. Tips for optimizing these systems include ensuring regular maintenance checks and employing advanced sensors to monitor performance in real-time.

Ultimately, understanding the basic components and functions of hydraulic lift valve manifolds provides significant advantages in the modern fluid control landscape. As technology continues to advance, innovations such as subsea electrification will further enhance the capabilities of these systems, leading to improved operational efficiencies and reduced downtime.

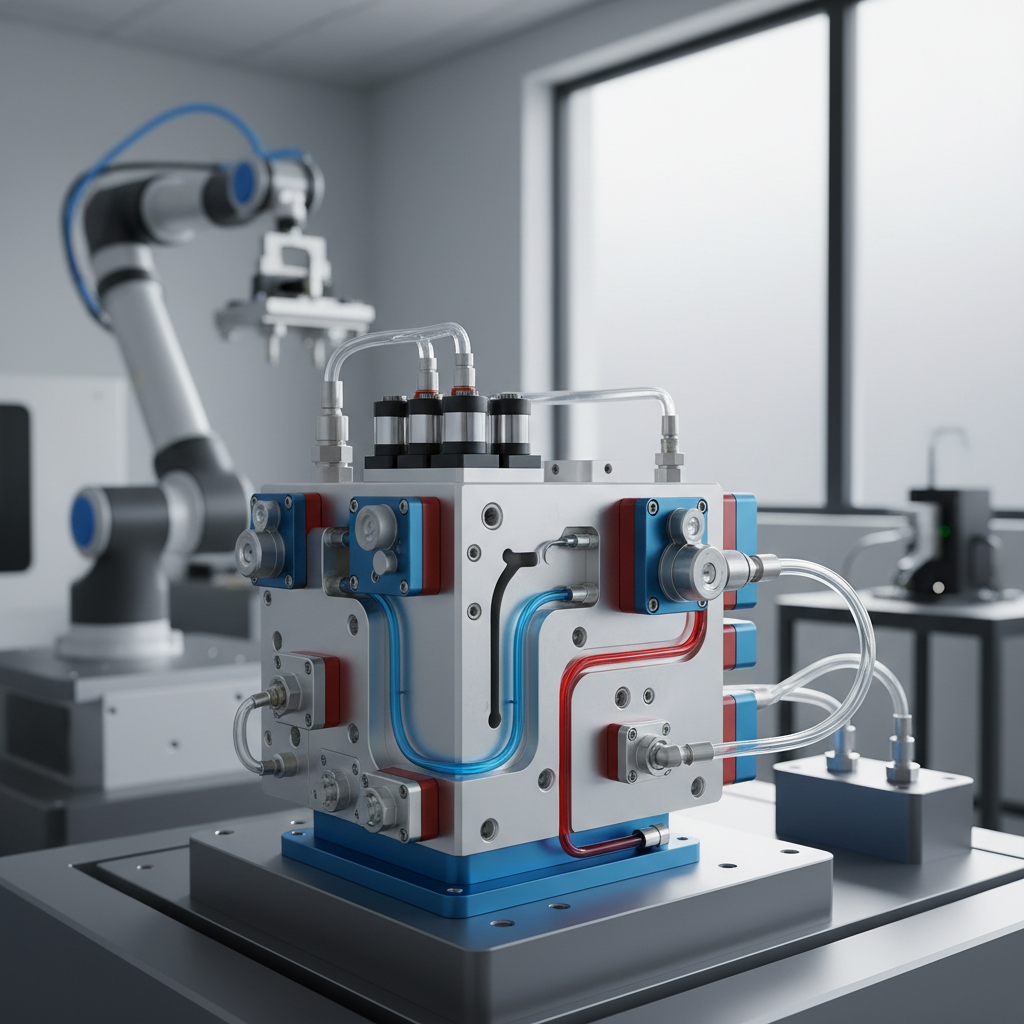

Hydraulic lift valve manifolds play a crucial role in optimizing fluid control systems by integrating key components that enhance efficiency. The primary components include hydraulic valves, which regulate fluid flow, along with filters that prevent contaminants from entering the system. Additionally, actuators are essential as they convert hydraulic energy into mechanical motion, thus facilitating precise control of lifting mechanisms.

According to industry reports, the efficiency of hydraulic systems can improve by over 30% with the proper configuration of manifolds, which balance pressure and flow more effectively during operation.

Tip: Regular maintenance of these components is vital. Inspections should be conducted to ensure that seals are intact and valves are functioning effectively to avoid leaks and improve overall system performance.

Furthermore, the design of a hydraulic lift valve manifold influences not just efficiency but also responsiveness. Advanced manifolds incorporate rapid response valves that enhance the speed of operation, which is critical in applications like construction or subsea operations.

Investing in quality hydraulic lift valve manifolds can significantly reduce downtime and increase productivity.

Tip: Consider the specific requirements of your application when selecting components. Choosing the right valve profiles can lead to more efficient fluid movement and better performance outcomes.

Hydraulic lift valve manifolds play a crucial role in optimizing fluid control systems by improving fluid flow rate and pressure regulation. By integrating multiple valves and controls into a single unit, manifolds facilitate seamless management of hydraulic fluids, allowing for more precise adjustments to flow and pressure. This centralized approach reduces the complexity of piping layouts and minimizes potential leak points, ultimately enhancing system reliability.

Efficiency metrics associated with these manifolds go beyond mere flow rate improvements. They enable quicker response times due to reduced fluid resistance and optimized pathways for fluid movement. Furthermore, pressure regulation can be finely tuned, ensuring that systems operate within desired parameters to prevent issues like cavitation or pump overloads. By utilizing hydraulic lift valve manifolds, industries can achieve significant energy savings and increased operational efficiency, making them an essential component in modern hydraulic systems.

Hydraulic lift valve manifolds play a crucial role in various industries where precise fluid control is essential. In construction, these manifolds enhance the operation of hydraulic excavators and cranes, ensuring that fluid distribution is optimized for lifting heavy loads. In the automotive sector, they are utilized in hydraulic braking systems, providing reliable control over braking pressure, thus increasing safety and performance. Furthermore, in manufacturing processes, hydraulic lift valve manifolds allow for the smooth operation of automated machinery, contributing to more efficient production lines.

Tip: Regular maintenance of hydraulic lift valve manifolds is vital for ensuring their optimal performance. Check for leaks and ensure that seals are in good condition to prevent fluid loss and ensure efficiency.

In aviation, hydraulic lift valve manifolds facilitate the operation of landing gear and flaps, making the function of aircraft more reliable and responsive. Meanwhile, in agriculture, they are employed in tractors and other equipment, helping farmers manage fluid control systems that are essential for various agricultural tasks. By employing hydraulic lift valve manifolds, these industries can significantly enhance their operational efficiency and safety.

Tip: Consider integrating pressure sensors with hydraulic lift valve manifolds to monitor system performance in real time, which can help preemptively address issues before they escalate.

The evolution of hydraulic manifold design is crucial for enhancing operational efficiency in fluid control systems. As industries continually seek more effective ways to manage hydraulic power, innovations such as modular designs and smart technology integration are emerging. These advanced manifolds are designed to reduce pressure drops and improve flow rates, ultimately leading to energy savings and increased productivity. The incorporation of IoT sensors also allows for real-time monitoring of system performance, enabling predictive maintenance and minimizing downtime.

Tips: To optimize the performance of hydraulic systems, regularly assess the condition of your hydraulic manifold. Look for signs of wear or leaks, as these can hinder efficiency. Additionally, consider investing in manifold systems that offer easy configurability to adapt to changing operational needs.

Another trend is the use of lightweight materials that not only reduce the weight of the hydraulic manifold but also improve heat dissipation. This is especially important in heavy-duty applications where overheating can lead to failures. The shift toward environmentally friendly designs is also notable, with manufacturers focusing on creating components that are easier to recycle and have less environmental impact during their lifecycle.

Tips: When selecting components for a hydraulic manifold, prioritize those that have high structural integrity while remaining lightweight. This can significantly enhance overall system efficiency and longevity.