Leave Your Message

In today's global market, understanding the intricacies of various hydraulic components is essential for buyers looking to optimize their operations. Among these components, Pipe Counterbalance Valves play a crucial role in ensuring the stability and safety of hydraulic systems. These valves provide essential support by counteracting gravitational forces, especially in applications where load handling is involved. In this ultimate guide, we will dive deep into the different types of Pipe Counterbalance Valves available in the market. We will explore their unique features, advantages, and potential drawbacks, equipping global buyers with comprehensive insights to make informed purchasing decisions. By comparing various designs and functionalities, this guide aims to illuminate the best options tailored to specific industry needs and operational requirements. Join us as we navigate the complexities of Pipe Counterbalance Valves to enhance your knowledge and facilitate better procurement choices.

Pipe counterbalance valves are essential components in hydraulic systems, providing stability and control in various applications. When considering these valves, there are several key features that every buyer should be aware of. First and foremost, the valve’s flow capacity is critical. A valve with the appropriate flow capacity ensures that the system can manage the required fluid volumes without causing pressure drops that can lead to inefficiency or system malfunctions.

Another important feature is the adjustment mechanism. Many pipe counterbalance valves come with adjustable settings that allow operators to tailor the valve's response to specific system demands. This adaptability is particularly valuable in applications where load variations are frequent. Additionally, buyers should look for valves that have robust construction materials to ensure durability and resistance to wear in demanding environments. This resilience not only prolongs the lifespan of the components but also reduces the frequency of maintenance and replacement, leading to lower operational costs in the long run.

| Feature | Description | Importance |

|---|---|---|

| Load Holding | Maintains load position under pressure | Ensures safety and stability during operation |

| Flow Direction | Controls the direction of hydraulic fluid | Crucial for the correct functioning of hydraulic systems |

| Pressure Settings | Adjustable pressure thresholds for different applications | Allows customization for various load conditions |

| Response Time | Speed at which the valve reacts to changes | Directly impacts the efficiency of the system |

| Size and Compatibility | Variety in sizes to fit different pipes and connectors | Essential for integration into existing systems |

| Material Quality | Durable materials to withstand pressure and corrosion | Enhances longevity and reduces maintenance needs |

Pipe counterbalance valves play a crucial role in fluid control systems by providing essential benefits that enhance the efficiency and safety of hydraulic operations. According to a report by MarketsandMarkets, the global hydraulic valve market is expected to reach USD 24.22 billion by 2026, underscoring the growing importance of effective fluid control solutions.

One of the standout benefits of using pipe counterbalance valves is their ability to maintain system stability by preventing unintended movement of hydraulic loads. This feature enhances operational safety, particularly in environments with heavy machinery, where sudden shifts can lead to accidents and equipment damage.

Additionally, pipe counterbalance valves contribute to energy efficiency in fluid control systems. A study published in the Journal of Hydraulic Engineering found that integrating counterbalance valves can reduce energy consumption by up to 15% in hydraulic systems by minimizing pressure fluctuations and maintaining consistent flow rates. This not only leads to lower operational costs but also supports sustainability initiatives within industries increasingly focused on reducing their carbon footprint.

The advantages offered by pipe counterbalance valves make them an essential component in modern fluid control systems, addressing both safety and efficiency needs in various applications worldwide.

When it comes to choosing the right pipe counterbalance valve, understanding your specific needs is essential. Start by identifying the system requirements, such as pressure ratings, flow rates, and installation space. A comprehensive assessment of your hydraulic system will guide you toward selecting a valve that can operate effectively under the conditions it will face. Proper selection not only enhances the efficiency of your system but also prolongs the longevity of your equipment.

Another crucial consideration is the design and functionality of the valve. Different types of pipe counterbalance valves have distinct features, such as load-holding capabilities and responsiveness to hydraulic pressure changes. Make sure to evaluate these functionalities based on the application they are intended for—whether it’s for lifting loads, controlling speed, or providing safety measures in your industry. Consulting with experts and leveraging detailed technical specifications can significantly aid in making an informed decision that meets operational demands while ensuring reliable performance.

When purchasing pipe counterbalance valves, it’s crucial to be aware of common mistakes that can lead to costly errors. One key mistake is underestimating the importance of selecting the correct pressure rating. Valves with insufficient ratings can fail under high pressure, causing safety hazards and equipment damage. Always refer to the manufacturer's specifications to ensure that the valve can handle the pressures it will encounter in your specific application.

Another frequent oversight is overlooking compatibility with existing systems. Buyers often assume that all valves will fit seamlessly into their setups, but differences in size, connection types, and flow rates can result in inefficiencies or, worse, system failures. It’s essential to take the time to verify that the counterbalance valves align with the requirements of your system, including materials that are compatible with the fluids being handled. By avoiding these common pitfalls, buyers can make more informed decisions, ensuring both safety and operational efficiency in their applications.

This chart illustrates the frequency of common mistakes global buyers make when purchasing pipe counterbalance valves. Understanding these pitfalls can help enhance decision-making and procurement strategies.

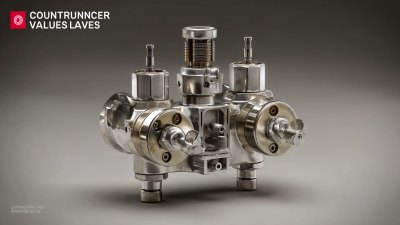

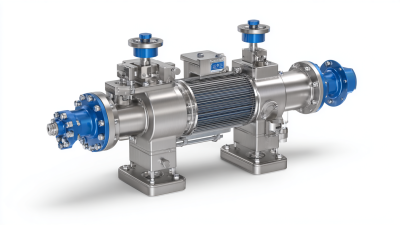

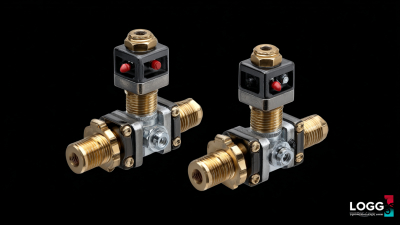

When it comes to selecting pipe counterbalance valves, understanding the leading brands and their distinct models is crucial for buyers across the globe. These valves play a vital role in maintaining system stability, especially in hydraulic applications. Each brand offers various models tailored to specific operational requirements, making it essential to conduct a comparative analysis. Evaluating factors like material composition, pressure ratings, and flow direction can significantly impact performance, especially when manufacturers use advanced engineering techniques to enhance durability and efficiency.

Additionally, as seen with recent product innovations across various industries, companies continuously strive to balance functionality with user experience. Notably, brands working on counterbalance valves are also focused on integrating modern technologies, similar to how other industries aim for a perfect blend of performance and design. This evolution aligns with the needs of today’s buyers who seek reliable products without compromising on quality or ease of use. Therefore, exploring the landscape of pipe counterbalance valves ensures buyers can identify the best options to meet their specific operational demands.