Leave Your Message

In the realm of hydraulic systems, Load Control Valves play a pivotal role in enhancing operational efficiency and ensuring optimal performance. According to industry reports, improperly adjusted load control valves can lead to significant energy losses, estimated at up to 30% in various applications. Moreover, failing to optimize these components may result in increased wear and tear on machinery, driving maintenance costs upwards by 25%.

To combat these inefficiencies, it is essential for engineers and operators to implement targeted strategies that maximize the performance of Load Control Valves. By adopting best practices in their deployment and maintenance, organizations can achieve not only better energy consumption rates but also improved system reliability and longevity. This article presents five essential tips designed to optimize Load Control Valves, paving the way for enhanced efficiency in hydraulic system operations.

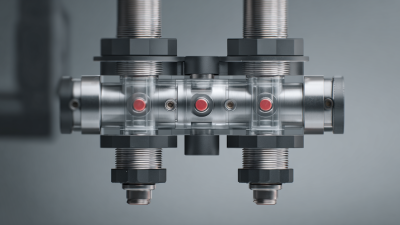

Load control valves play a pivotal role in enhancing process efficiency across various industrial applications. These components regulate the flow of fluids, ensuring that systems operate within optimal parameters. Understanding their functionality is crucial for maximizing their potential. By maintaining appropriate pressure differentials and flow rates, load control valves help prevent energy wastage, reduce operating costs, and improve overall system performance.

Effective optimization of load control valves involves a comprehensive understanding of the specific processes they serve. This includes assessing the flow characteristics and identifying the ideal valve size and configuration for the application. Furthermore, regular maintenance and timely adjustments are essential to ensure that these valves are operating efficiently over time. By paying close attention to these factors, industries can achieve significant improvements in productivity and energy efficiency, highlighting the integral role of load control valves in modern process management.

This chart illustrates the efficiency improvements associated with five essential tips for optimizing load control valves.

When it comes to optimizing valve sizing for load control valves, achieving ideal flow rates is crucial for enhanced performance. The first step in this process is to accurately assess the system's requirements, including the fluid type, temperature, and pressure ranges. By understanding these variables, engineers can select valves that are appropriately sized to minimize pressure drops while maximizing flow efficiency. This careful consideration ensures that the valve operates within its optimal range, reducing wear and tear and prolonging its lifespan.

When it comes to optimizing valve sizing for load control valves, achieving ideal flow rates is crucial for enhanced performance. The first step in this process is to accurately assess the system's requirements, including the fluid type, temperature, and pressure ranges. By understanding these variables, engineers can select valves that are appropriately sized to minimize pressure drops while maximizing flow efficiency. This careful consideration ensures that the valve operates within its optimal range, reducing wear and tear and prolonging its lifespan.

Additionally, maintaining accurate flow rates can significantly impact the overall system's efficiency. Utilizing flow measurement tools in conjunction with the chosen valves can provide real-time feedback, allowing for adjustments as necessary. Regular maintenance and inspection of the valves also contribute to consistent performance, ensuring that they remain in good working condition. By prioritizing these factors, organizations can enhance their operational efficiency and reduce energy waste, ultimately leading to a more sustainable and cost-effective system.

Regular maintenance practices are crucial for load control valves to minimize downtime and extend their lifespan. According to industry reports, maintenance strategies that prioritize proactive planning and advanced diagnostics can significantly reduce equipment failure rates. For instance, implementing a routine check-up schedule based on operating hours and load conditions not only enhances performance but also ensures that any potential issues are identified before they escalate.

Additionally, insights from the energy sector reveal that predictive maintenance can lead to up to a 30% reduction in maintenance costs, highlighting the importance of data-driven approaches in maintenance protocols. By integrating predictive analytics, operators can forecast failure points and optimize service schedules accordingly. This approach not only maximizes uptime but also allows for better resource allocation, aligning closely with the emerging trends in effective load control valve management.

Implementing these practices will undoubtedly enhance the efficiency of operations while extending the service life of critical components.

Optimizing load control valves is vital for enhancing operational efficiency in various industrial applications. One key strategy lies in leveraging data analytics to monitor performance continuously. Industry reports indicate that organizations utilizing advanced data analytics can achieve up to a 15% increase in operational efficiency through real-time performance tracking. This empowers maintenance teams to identify potential issues before they escalate, ensuring that valves operate within their optimal parameters.

To effectively utilize data analytics, consider implementing these tips: First, establish a baseline performance metric to monitor changes over time. This allows you to quickly identify deviations that may indicate inefficiencies. Second, use predictive maintenance tools that analyze historical performance data to forecast potential failures, which can lead to significant cost savings. According to a recent survey by the International Society of Automation, companies that adopted predictive maintenance strategies reported a 20% reduction in downtime, drastically improving productivity.

Lastly, ensure that your data collection methods are robust and comprehensive. Incorporating IoT devices can provide granular insights into the functioning of load control valves. By continuously collecting and analyzing this data, businesses can adapt their operations in real-time, resulting in sustained efficiency and reduced operational costs.

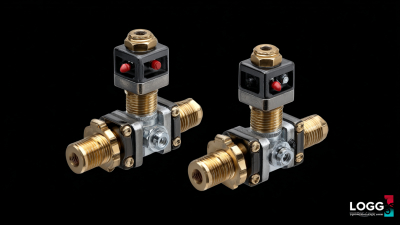

Innovative technologies are revolutionizing the management of load control valves, enabling more effective real-time load management. By integrating smart systems, operators can monitor and adjust valve settings dynamically based on current operational demands. This not only enhances efficiency but also allows for predictive maintenance, reducing downtime and improving overall system reliability. Real-time data analytics play a crucial role in this integration, providing actionable insights that empower engineers to make informed decisions.

The implementation of IoT (Internet of Things) devices further enhances load control capabilities. With sensors and connected devices, operators gain access to live monitoring, enabling them to respond swiftly to fluctuations in load conditions. This proactive approach minimizes energy waste and optimizes resource allocation. Additionally, machine learning algorithms can analyze historical performance data, leading to continuous improvement in the optimization strategies used for load control valves. Embracing these innovative technologies leads to a more sustainable and efficient operational environment.