Leave Your Message

Counterbalance valves play a crucial role in optimizing hydraulic system performance, ensuring both efficiency and safety during operation. These valves are designed to control the motion of hydraulic actuators, particularly in applications where load conditions can vary significantly. By maintaining system pressure and counteracting the effects of gravity, counterbalance valves prevent uncontrolled descent of loads, thereby protecting both the machinery and the operator.

With the increasing complexity of hydraulic systems in various industries, the need for reliable and effective control mechanisms like counterbalance valves has become more important than ever. Their ability to regulate fluid flow and maintain hydraulic pressure under dynamic conditions enhances the overall stability and responsiveness of the system. As we explore the functionalities and benefits of counterbalance valves, it becomes evident that they are not merely components but essential elements for achieving optimal hydraulic system performance.

Hydraulic systems are integral to a multitude of industrial and mobile applications, offering incredible force and precision. At the heart of these systems lie various essential components, each playing a pivotal role in overall performance. Among these components, the counterbalance valve stands out due to its ability to provide stability and control. According to the Hydraulic Institute, an estimated 15% of all hydraulic system failures can be attributed to inadequate hydraulic control mechanisms, highlighting the critical impact that proper valve functionality has on system integrity.

Counterbalance valves are specifically designed to manage load-induced pressure and prevent unwanted movement, thereby enhancing operational safety and efficiency. When a heavy load is present, the valve maintains necessary system pressure, ensuring that the actuator operates smoothly and predictably. The 2021 Fluid Power Trends report indicates that implementing advanced hydraulic control components, including counterbalance valves, can improve energy efficiency by up to 20%, showcasing their significance in reducing operational costs while maintaining performance reliability.

Moreover, understanding the operational principles of hydraulic systems and their components further emphasizes the indispensable nature of counterbalance valves. The ability to control motion under varying loads is crucial; without these valves, systems become prone to erratic behavior and potential failures. A comprehensive knowledge of hydraulic components empowers engineers and technicians to design more robust systems, effectively extending their lifespan and enhancing productivity across various industries.

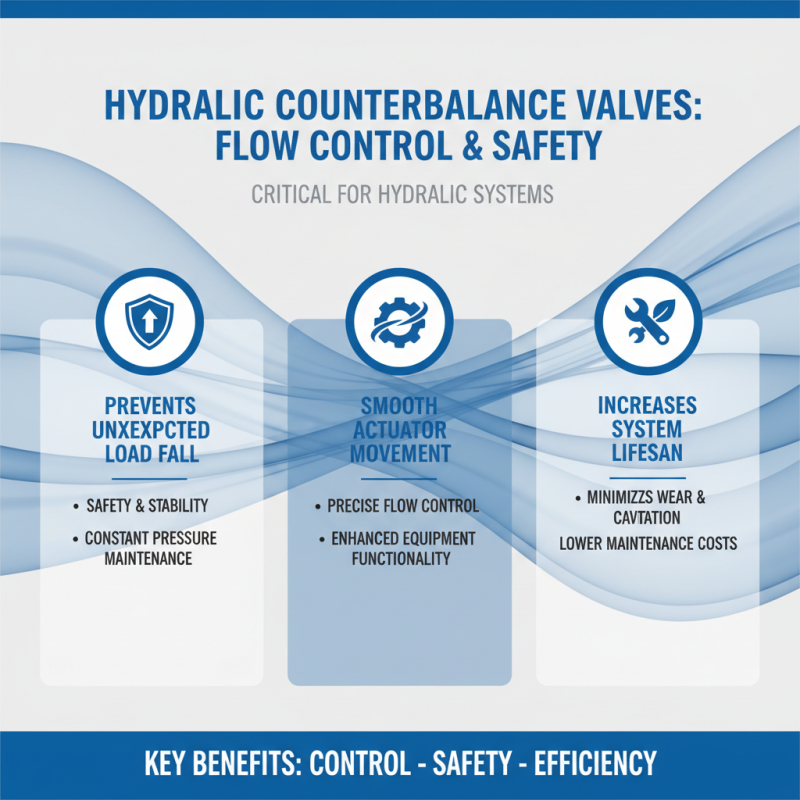

Counterbalance valves are critical components in hydraulic systems, particularly when it comes to effective flow control. They play a pivotal role in ensuring that the load does not fall unexpectedly, providing safety and stability during operations. By maintaining a constant pressure in the system, these valves allow for smooth movement of hydraulic actuators, which enhances the overall functionality and efficiency of equipment. This precise control over flow prevents cavitation and minimizes wear on system components, ultimately leading to longer service life and lower maintenance costs.

Tips for optimizing the use of counterbalance valves include regular maintenance and monitoring of pressure settings. Keeping the valves clean and adjusting them according to the specific needs of the application can significantly improve performance. Additionally, understanding the dynamics of your hydraulic system and load characteristics can help in selecting the appropriate specifications for counterbalance valves, ensuring they function effectively without creating unnecessary resistance.

Furthermore, it's essential to consider the placement of counterbalance valves within the hydraulic circuit. Proper positioning can enhance their effectiveness in flow control, allowing for quicker response times and greater system reliability. By strategically integrating these valves into your hydraulic setup, you can achieve better control over movements, thereby increasing productivity and safety in operations.

Counterbalance valves play a critical role in enhancing the performance and safety of hydraulic systems. One of the primary benefits they provide is the ability to maintain load control during operations, particularly in applications involving lifting and lowering heavy loads. According to a report by the International Fluid Power Society, properly integrated counterbalance valves can reduce potential load drops by up to 50%, significantly minimizing the risk of accidents and damage to equipment. This control is essential for maintaining operational efficiency and worker safety in industries such as construction, manufacturing, and transportation.

In addition to safety benefits, counterbalance valves contribute to overall system efficiency. They manage the flow of hydraulic fluid, ensuring that the system responds promptly to changes in load conditions. A study from the Hydraulic Institute indicates that systems equipped with counterbalance valves can experience up to a 30% increase in energy efficiency compared to those without. This improvement not only reduces operational costs but also lessens the environmental impact of hydraulic operations by minimizing energy consumption. As hydraulic systems become more integral to automated processes, the significance of counterbalance valves in optimizing performance cannot be overlooked.

Counterbalance valves play a critical role in various industrial machinery applications by ensuring stability and control during operation. They are primarily used in systems where load-bearing components are involved, such as hydraulic lifts, excavators, and cranes.

By allowing fluid to flow in one direction while preventing backflow under load, these valves maintain the position of a load and enhance safety. In situations where precise movement and control are crucial, counterbalance valves effectively manage the hydraulic pressure and prevent unintended descent of heavy loads, which is essential for operator safety.

In addition to their safety features, counterbalance valves contribute to the efficiency of hydraulic systems. By minimizing the risk of uncontrolled movement, they enable smoother and more precise operation of machinery. This results in reduced wear and tear on components, leading to longer equipment life and lower maintenance costs.

Industries such as construction, manufacturing, and material handling leverage counterbalance valves to optimize performance in machinery like telehandlers, industrial forklifts, and material conveyors. Ultimately, their implementation not only improves operational safety but also enhances productivity in various industrial settings.

Counterbalance valves play a crucial role in maintaining stability and controlling motion within hydraulic systems. However, several common issues can arise with these components, potentially compromising the performance and safety of the entire system. One prevalent issue is the lack of proper adjustment during installation, which can lead to erratic or sluggish machine movement. According to industry reports, nearly 30% of hydraulic system failures are attributed to poorly calibrated components, including counterbalance valves. Regular maintenance and precise adjustments are essential for optimizing the flow and pressure, ensuring seamless operation.

Another common problem involves contamination in the hydraulic fluid, which can obstruct the valve’s operational efficiency. Particulate matter and water can deteriorate the seals and create sticking issues, ultimately leading to failures in load holding and control. Research indicates that up to 70% of hydraulic failures can be traced back to fluid contamination. Solutions to this issue include implementing effective filtration systems and conducting regular fluid checks to maintain cleanliness and performance. By addressing these common issues proactively, operators can enhance the reliability and longevity of their hydraulic systems, maximizing productivity and minimizing downtime.

| Dimension | Details |

|---|---|

| Function | Maintain load stability and control motion in hydraulic systems. |

| Common Issue | Leakage due to wear or damage of seals. |

| Solution | Regular maintenance and timely replacement of seals. |

| Pressure Control | Prevention of hydraulic shocks and maintaining system integrity. |

| Testing | Routine pressure and flow testing to ensure proper function. |

| Installation Factors | Correct placement and orientation affecting performance. |

| Response Time | Critical for applications requiring precise control. |