Leave Your Message

In industrial applications, choosing the right Flow Control Valves is crucial. According to a recent report by the Global Valve Market Research, the demand for Flow Control Valves is projected to reach $18 billion by 2026. This highlights their importance across various sectors, including oil and gas, water treatment, and manufacturing.

John Smith, an expert in fluid dynamics, stated, "Selecting the correct Flow Control Valves can significantly enhance operational efficiency." His insights emphasize that the right valve can prevent leaks and reduce energy consumption, proving vital for cost management. Many operations overlook valve specifications, risking performance failures.

Valves come in various designs and materials, each with unique attributes. For instance, ball valves are known for their durability, while globe valves offer fine-tuning abilities. The diversity makes the selection process complex. Often, users focus only on cost or availability, neglecting compatibility and performance. Reflection on common mistakes is necessary to make informed decisions. Choosing the wrong valve impacts productivity and may lead to catastrophic failures.

Flow control valves play a crucial role in managing fluid flow in various applications. Understanding the basics helps in making informed choices. These valves regulate the flow rate and pressure of liquids and gases. They can be classified into several types, including needle valves, ball valves, and gate valves. Each type has its specific function and suitability for different scenarios.

When choosing a valve, consider the application requirements. The material of the valve is critical, as it affects durability and compatibility with fluids. Accurate sizing is also essential. An incorrectly sized valve can lead to inefficiencies or failures. It's important to evaluate the working conditions, such as temperature and pressure.

However, even with proper knowledge, errors can still occur. A common mistake is ignoring the maintenance needs of flow control valves. Regular inspection and upkeep are necessary for optimal performance. Users often overlook this aspect, leading to unexpected breakdowns. Reflecting on these mistakes can lead to better decision-making in the future.

When selecting flow control valves, several key factors come into play. Understanding your application is crucial. Consider the type of fluid flowing through the system. Liquids behave differently than gases. Viscosity and temperature also matter. These factors influence the valve's performance.

Tip: Always check the specifications! Look at compatibility with media. This can prevent costly failures later.

Another important factor is the flow rate. It’s the amount of fluid passing through the valve. Be realistic about your needs. Oversizing or undersizing can lead to inefficiencies. Also, review pressure ratings carefully.

Tip: Calculate your system’s requirements! It will help you narrow down your choices. Testing different valves before finalizing can reveal unexpected results. Consider how the valve will be installed as well. Accessibility for maintenance should not be overlooked.

In the end, balancing these factors helps in making a wise decision. Remember, what works for one setup might not suit another. Analyze your specific requirements thoroughly.

When it comes to flow control valves, understanding flow rate requirements is essential. Different applications have unique needs. For example, industrial processes may require high flow rates for efficient operation. In contrast, precision applications demand much lower rates to avoid damaging sensitive components. Considering these aspects is crucial for selecting the right valve.

Evaluating the flow rate begins with assessing the system requirements. Gather data about the maximum and minimum flow rates needed. A valve that accommodates these variations can greatly enhance performance. Pay attention to the fluid characteristics, such as viscosity and temperature. These factors can influence how the fluid flows through the valve.

It's also important to consider the potential for mistakes. A valve selected for a specific flow rate might not perform well under different conditions. Constant monitoring is necessary to ensure optimal performance. Adjustments may be needed as the system operates and conditions change. Reflecting on these points will lead to better choices in valve selection.

Selecting the right flow control valves involves understanding material compatibility. Different environments require different materials. Stainless steel, plastic, and brass are common choices. Each material reacts differently to various fluids, temperatures, and pressures. For example, stainless steel resists corrosion but can be costly. Plastic may be more affordable but has limitations on temperature.

Incompatible materials may lead to leaks or failures. It is crucial to analyze the application's specific conditions. Fluids may include water, chemicals, or gases. Each has unique characteristics. Testing is necessary to ensure durability. Overlooking this step can result in significant problems.

Consider the environment where the valve will operate. Factors like temperature, pressure, and fluid type play a vital role. If a valve is subjected to extreme conditions, the choice of material can make or break its performance. Sometimes, standard materials aren't enough. Custom solutions might be necessary, which could complicate the selection process. Balancing cost with performance is often challenging. Careful analysis is essential to avoid mishaps.

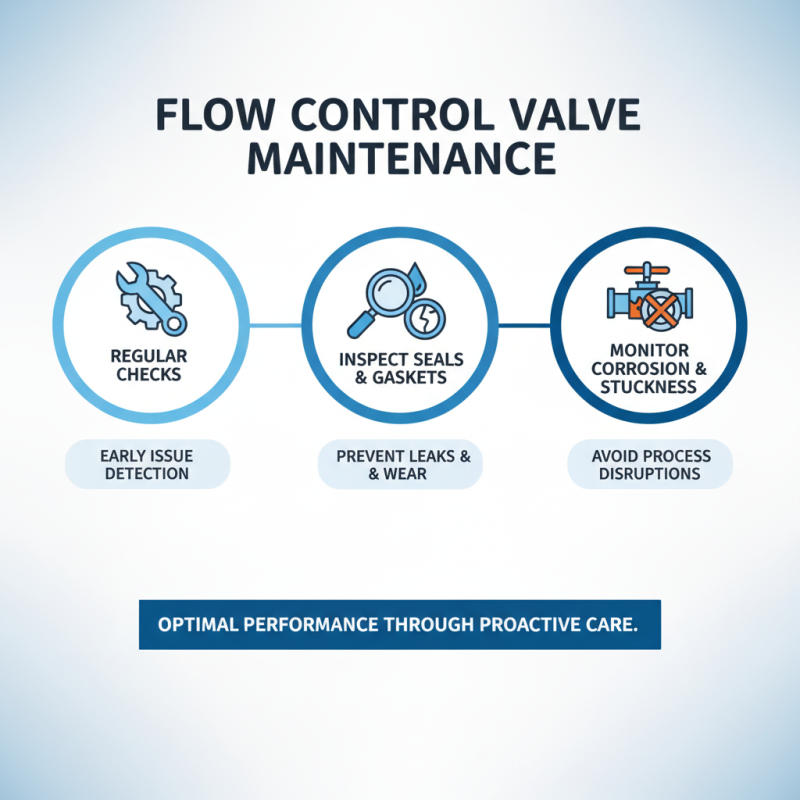

Maintaining flow control valves is crucial for optimal performance. Regular checks help identify issues early. For instance, inspect seals and gaskets for wear or leakage. Corrosion can affect function. A quick visual assessment can be revealing. Imagine a valve stuck open. This can cause significant process disruptions.

The operational environment plays a key role in valve maintenance. High temperatures or pressure fluctuations might accelerate wear. Adjusting operational parameters can sometimes help reduce stress on the valves. Keeping records of maintenance activities is essential, too. You might forget what you did last month. A log can provide insights and track recurring problems.

Consider conducting periodic tests to evaluate valve performance. Flow rates and response times can reveal hidden issues. Remember, not all problems are visible at first glance. Sometimes, it takes time to notice changes. Gathering feedback from operators can uncover challenges they face. Engaging them fosters a culture of continuous improvement.