Leave Your Message

Choosing the right unidirectional throttle valves is crucial for optimal system performance. These valves control the flow of fluids in one direction, ensuring efficiency and preventing backflow. When selecting a unidirectional throttle valve, consider various factors. Each application may have unique requirements, and it's essential to match the valve specifications to those needs.

The size, material, and pressure rating of unidirectional throttle valves can greatly affect their functionality. Often, users overlook the importance of these details. It’s not just about installation; understanding the environment and operating conditions is equally vital. A mismatch can lead to leaks or malfunctions, causing unexpected costs and downtime.

Moreover, evaluating the quality of the valve is vital. Not all valves are created equal, and some may not perform as expected. User feedback and trusted brands often provide good insights. Think about the potential for failure and how it affects your system. Each decision can have lasting impacts. Take your time, do the research, and ensure that the selected unidirectional throttle valves meet your specific needs.

Unidirectional throttle valves are crucial in controlling fluid flow in various applications. They allow flow in one direction while preventing backflow. This is essential in numerous industries, including automotive, aerospace, and chemical processing. According to recent industry reports, the global market for throttle valves is expected to grow at a CAGR of 4.5% from 2023 to 2030. This growth indicates a rising demand for effective fluid control solutions.

Understanding the specific applications of unidirectional throttle valves is key. For instance, in hydraulic systems, these valves prevent fluid from returning to the pump, ensuring system efficiency. In the automotive sector, these valves help manage air intake for engines. However, not all throttle valves are equal. Factors like size, material composition, and pressure ratings play significant roles in their performance. A mismatch can lead to inefficiencies or even system failures.

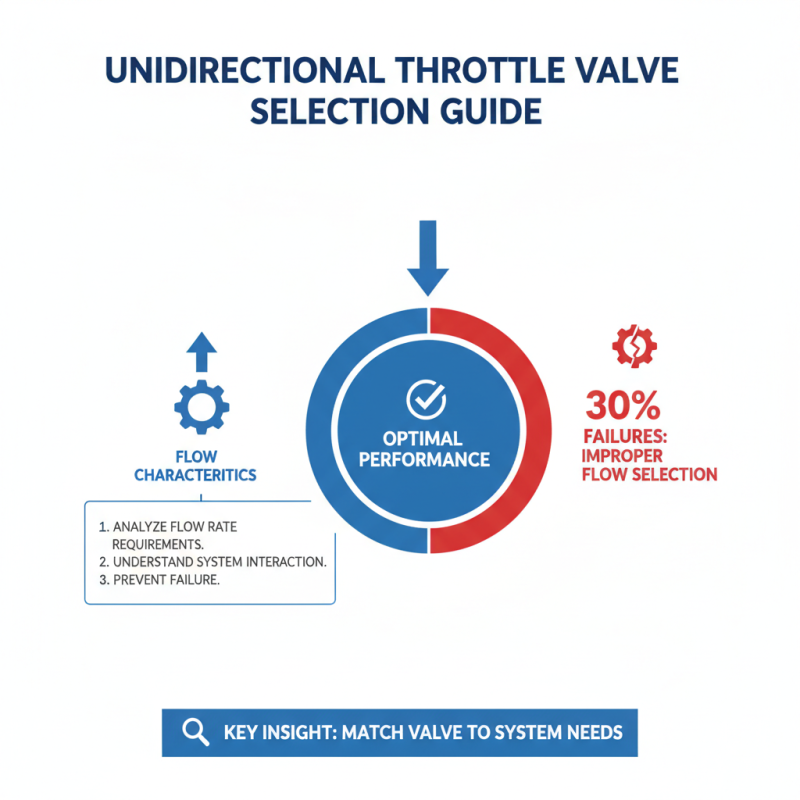

It's important to critically assess the actual needs before choosing a valve. Too often, engineers focus solely on specifications, neglecting installation and maintenance aspects. Reports show that improper valve selection can result in up to 30% energy loss in industrial systems. Such data highlights the need for thoughtful decision-making when selecting unidirectional throttle valves for specific applications. Understanding the flow characteristics and environmental conditions can enhance system reliability and performance.

This chart compares the flow rates of different types of unidirectional throttle valves. It is essential to analyze these metrics when selecting the right throttle valve for specific applications.

When selecting unidirectional throttle valves, consider the flow characteristics. It is crucial to analyze the flow rate requirements of the application. For example, industry reports indicate that 30% of throttle valve failures are due to improper flow rate selection. An adequate understanding of how the valve will interact with the system is vital for optimal performance.

Next, examine the material compatibility. Valve body materials must withstand environmental factors and fluid types. A report from the Fluid Control industry states that 25% of valve failures arise from corrosion, emphasizing the need for durable materials. Leaks can cause significant downtime. The choice of seals and gaskets also plays a role in maintaining integrity under pressure.

Finally, assess the size and pressure ratings. Oversized valves can lead to inefficient operation. In contrast, undersized valves may not handle the system’s demands. The right size can reduce energy consumption by up to 20%, according to recent studies. Evaluating pressure ratings is equally important, as many valves are rated for specific pressure ranges, and exceeding them can lead to failures and costly repairs.

When selecting unidirectional throttle valves, material choice is crucial. Different materials can significantly affect the valve's performance and durability. For instance, stainless steel offers excellent corrosion resistance and strength. According to industry data, valves made from stainless steel can last up to 50% longer than those made from plastics in corrosive environments. However, the cost may be a concern.

On the other hand, materials like PVC are lightweight and cost-effective for specific applications. They perform well in non-corrosive systems but may deform under high-pressure conditions. Reports suggest that PVC valves may require replacement every 3 to 5 years, depending on the usage. Evaluating the specific environment and operational conditions is necessary.

Some manufacturers still use materials that might not withstand extreme temperatures. This could lead to failures that are costly and time-consuming to address. Choosing a suitable material involves balancing cost, performance, and expected lifespan. Understanding these factors will help in making a more informed decision. It's an ongoing challenge that requires careful consideration.

| Material Type | Durability Rating | Temperature Resistance (°C) | Corrosion Resistance | Weight (kg) |

|---|---|---|---|---|

| Stainless Steel | High | 200 | Excellent | 5.0 |

| Aluminum | Moderate | 150 | Good | 3.0 |

| Bronze | High | 180 | Very Good | 4.5 |

| Plastic | Low | 100 | Fair | 1.5 |

| Carbon Steel | Moderate | 220 | Good | 6.0 |

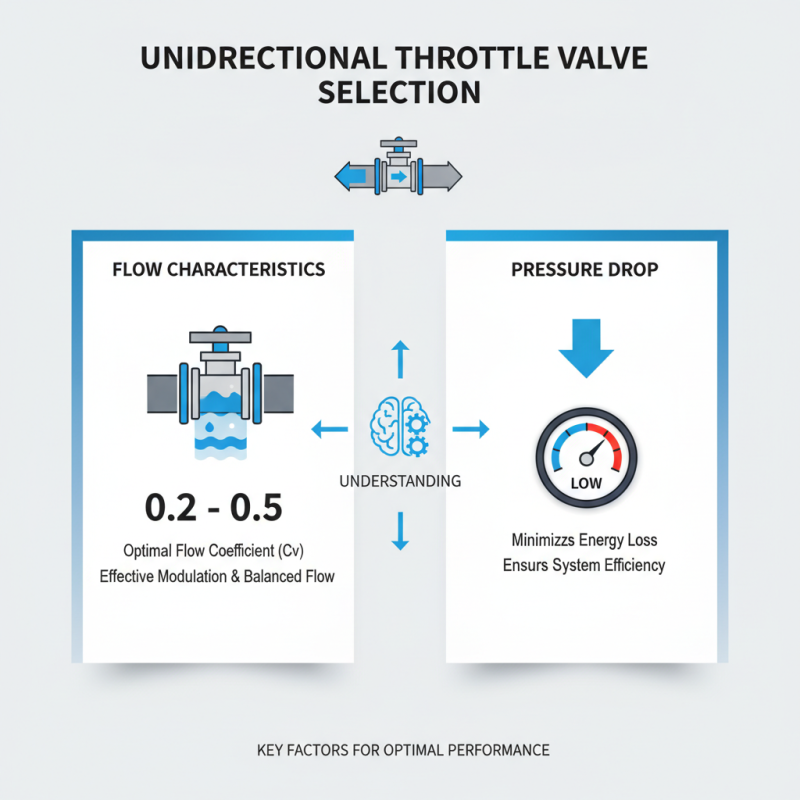

Choosing the right unidirectional throttle valve involves understanding flow characteristics and pressure drop. Flow characteristics are critical when selecting a valve, as they impact efficiency. According to a recent industry report, the optimal flow coefficient (Cv) for valves typically ranges from 0.2 to 0.5. This range allows for effective modulation while maintaining a balanced flow rate.

Pressure drop is another key factor. A valve that reduces pressure too much can lead to energy inefficiency. The American Mechanical Engineers Association notes that a pressure drop exceeding 10% across the valve can significantly hinder performance. Maintaining a low-pressure drop can enhance system reliability, yet achieving this balance often proves challenging.

Real-world applications show that oversizing valves leads to unnecessary complexities. A valve that is too large may create turbulence, counteracting its intended purpose. Users should, therefore, analyze system needs carefully. They need to consider both average and peak flow rates to find a suitable valve size. As experts suggest, a deep dive into the hydraulics of each system ensures better outcomes.

Proper installation and maintenance of unidirectional throttle valves are crucial for ensuring their optimal performance. According to industry reports, improperly installed valves can lead to a 20% loss in efficiency. Accurate alignment during installation is essential. Incorrect positioning can cause wear and tear, leading to premature failure. Verification of specifications and compatibility with piping systems is vital. A misaligned valve affects flow rates and can damage your system over time.

Regular maintenance is equally important. A study published in the Journal of Valve Engineering indicates that routine checks can extend a valve's lifespan by up to 30%. Inspect for leaks, corrosion, or debris buildup. Cleaning the valve regularly helps prevent performance degradation. Marked maintenance intervals should be established based on usage and operating conditions. Many overlook routine service, which leads to unexpected breakdowns. Users must develop a disciplined maintenance schedule to ensure longevity and reliability.

Monitoring performance can help detect issues early. Keep track of pressure drops and flow variations. These signs may indicate valve malfunction or blockage. Addressing these concerns promptly is critical. Failure to respond can escalate minor problems into costly repairs. Emphasizing proactive maintenance practices significantly impacts overall system performance.