Leave Your Message

In the modern industrial landscape, the efficiency and reliability of hydraulic systems are paramount. According to a report by MarketsandMarkets, the global hydraulic valve market is projected to reach USD 25.49 billion by 2023, growing at a CAGR of 5.83% from 2018. A critical component in these systems is the Hydraulic Lift Valve Manifold, which plays an essential role in managing fluid flow across various hydraulic circuits. Selecting the right manifold is crucial for optimizing system performance, reducing maintenance costs, and ensuring safety in operations.

The choice of hydraulic lift valve manifold can significantly impact the overall efficiency and effectiveness of hydraulic applications in industries such as construction, automotive, and manufacturing. A well-designed manifold can minimize energy loss, streamline installation, and enhance durability under extreme operating conditions. As hydraulic systems become increasingly sophisticated, understanding the specifications, pressure ratings, and compatibility of manfolds is vital for engineers and decision-makers aiming to achieve operational excellence while adhering to stringent safety standards.

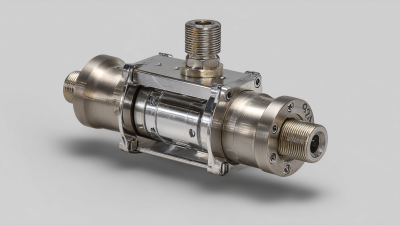

When exploring hydraulic lift valve manifolds, it's essential to first grasp their fundamental components and functions. A hydraulic lift valve manifold acts as a central hub that controls multiple hydraulic valves within a system. It typically comprises several ports that connect to hydraulic cylinders or motors, allowing for the efficient distribution of fluid and enhancing the overall performance of hydraulic systems. Understanding the flow paths and the arrangement of these valves is crucial for optimizing system efficiency and responsiveness.

Moreover, choosing the right manifold requires an understanding of the operational demands of your hydraulic system. Factors such as pressure ratings, flow capacity, and the specific configuration of hydraulic lines must be considered. It's also important to evaluate the manifold's material construction to ensure compatibility with the fluids used in the application. An effective selection will not only improve the functionality of your hydraulic lift system but also enhance reliability and maintenance intervals, ultimately leading to cost savings and improved operational efficiency. Understanding these basics forms the foundation for making informed decisions about hydraulic lift valve manifolds tailored to specific needs.

When selecting a hydraulic lift valve manifold, it is crucial to first identify your hydraulic system requirements. A comprehensive understanding of your application is vital, as improper selection can lead to compromised system efficiency and increased operational costs. According to the International Fluid Power Society, nearly 30% of hydraulic system failures can be traced back to incorrect manifold selection. This highlights the importance of assessing factors such as pressure ratings, flow rates, and the type of hydraulic fluid being utilized.

Understanding the specific needs of your application includes evaluating the load requirements and the cycle frequency of your hydraulic system. For instance, a recent report by the National Fluid Power Association indicated that systems designed for high-cycle applications require more robust components to handle the increased fatigue. Additionally, consider environmental factors such as temperature fluctuations and the presence of contaminants, as they can significantly impact the performance and longevity of the hydraulic manifold. Identifying these parameters can help streamline the selection process, enabling users to choose manifolds that not only fit their current needs but also provide adaptability for future expansions.

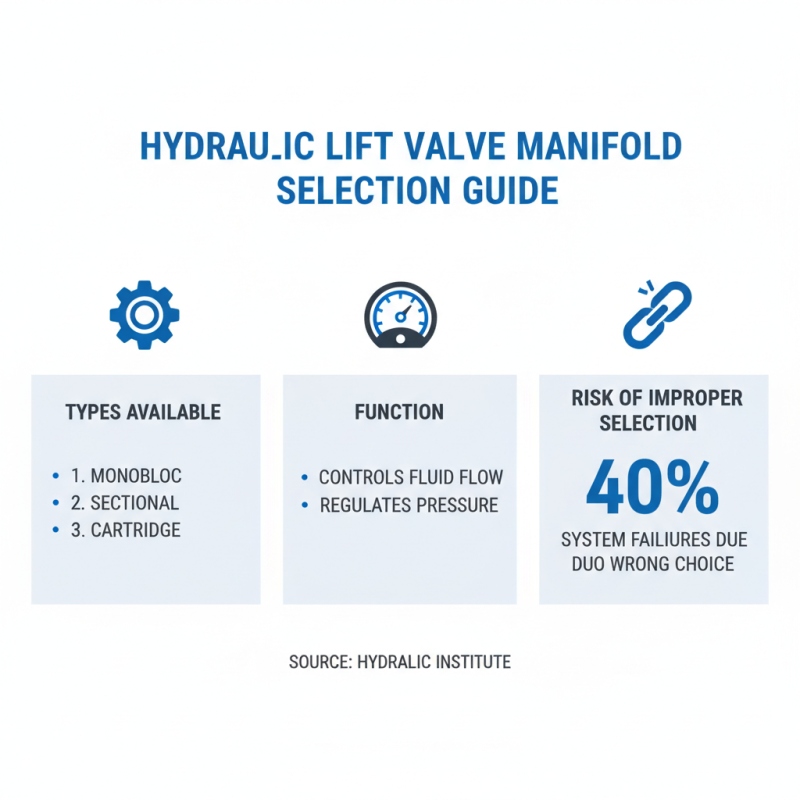

When selecting the right hydraulic lift valve manifold, it is crucial to evaluate the different types available on the market. Hydraulic lift valve manifolds are integral components in various systems, facilitating the control of fluid flow and pressure. According to the Hydraulic Institute, approximately 40% of hydraulic system failures are attributed to improper component selection, underscoring the importance of understanding the manifold types and their specifications.

There are generally three main types of hydraulic lift valve manifolds: subplate-mounted, manifold block, and integrated manifolds. Subplate-mounted manifolds offer flexibility and ease of maintenance, making them suitable for systems requiring frequent adjustments. In contrast, manifold blocks provide a compact design, ideal for space-constrained applications. Integrated manifolds combine multiple functions into a single unit, optimizing performance and reducing potential failure points. Industry reports indicate that integrated manifolds can enhance operational efficiency by up to 30%, making them a popular choice among engineering professionals.

When making a decision, consider factors such as the flow capacity, pressure ratings, and compatibility with existing components. A recent survey conducted by the Fluid Power and Motion Control (FPMC) Association highlights that 65% of businesses prioritize hydraulic manifold efficiency as a key performance indicator. Understanding these dynamics will help you choose a manifold that aligns with both operational needs and long-term reliability goals.

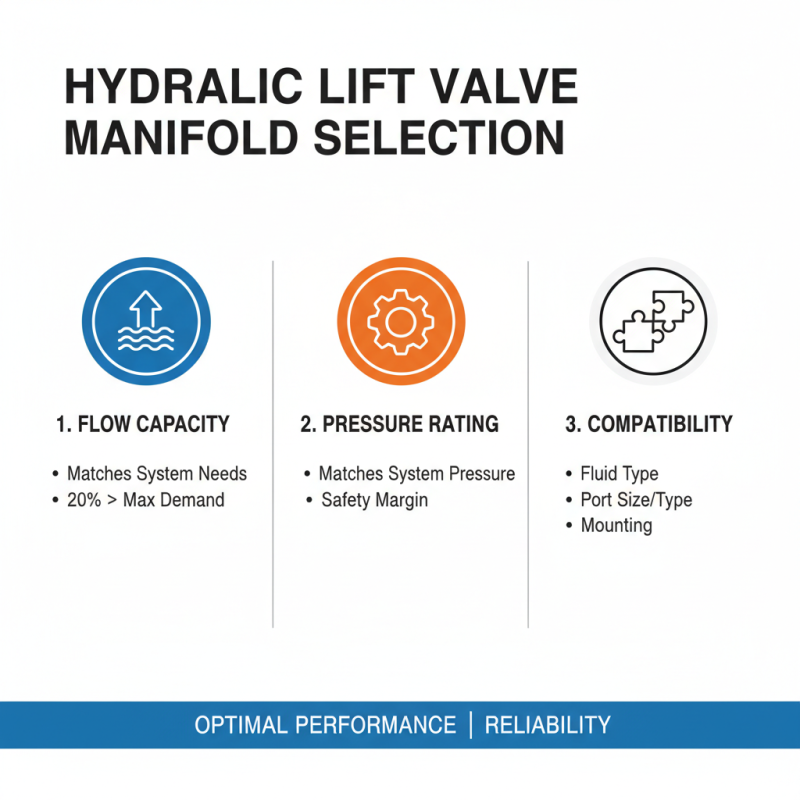

When selecting a hydraulic lift valve manifold, several critical factors must be considered to ensure optimal performance and compatibility within your hydraulic system. First, the flow capacity is paramount. According to industry reports, hydraulic systems require specific flow rates to operate efficiently, so choosing a manifold that can accommodate these rates will prevent bottlenecks and ensure smooth operation. Research indicates that a manifold should ideally have a flow capacity that exceeds the maximum expected demand by at least 20% to provide the necessary headroom for varying conditions.

Additionally, pressure ratings play a crucial role. It is essential to choose a manifold that can sustain the maximum pressure levels experienced in your system without compromising safety or functionality. Most hydraulic systems operate within a range of 3000 to 5000 psi; thus, selecting a manifold with a higher pressure rating can enhance durability and reliability.

**Tips**: When evaluating options, check for compatibility with hose sizes and fittings in your existing system. Understanding connection types and ensuring that they align with your hydraulic components will simplify installation and reduce the risk of leaks. Furthermore, material compatibility is essential; selecting a manifold made from corrosion-resistant materials can significantly extend operational life in hostile environments. Always consult technical specifications or a hydraulic engineer when in doubt, to ensure your choices are sound and well-suited for your unique application.

Hydraulic lift valve manifolds are critical components in various industries, allowing for efficient control of hydraulic systems. Proper maintenance and care of these systems can dramatically extend their lifespan and improve performance. According to industry reports, neglecting regular maintenance can lead to a significant reduction in operational efficiency, often resulting in failures that are costly to resolve.

To ensure optimal performance, it is essential to implement routine checks and maintenance schedules. One key tip is to regularly inspect the manifold for any signs of wear or leakage. This can help identify potential problems early, saving time and resources. It’s also advisable to keep the hydraulic fluid at the recommended level and to change it according to the manufacturer’s guidelines. Dirty or contaminated fluid can lead to wear and tear on the manifold components, thereby reducing their effectiveness.

Another important aspect of care is ensuring that all connections and fittings are tight and secure. Vibration during operation can loosen these connections, leading to inefficient operation or even system failure. Routine tightening and torque checks can prevent such issues. Finally, consider using filtration systems to maintain fluid cleanliness, as contaminants can severely impact the performance and reliability of hydraulic systems. By following these tips, users can optimize the longevity and reliability of their hydraulic lift valve manifolds.