Leave Your Message

Selecting the right flow control valves can significantly impact system performance. Expert engineer Dr. Sam Johnson emphasizes, “Choosing the right valves is key to efficient fluid management.” This statement encapsulates the importance of understanding various flow control valves and their applications.

Flow control valves regulate fluid flow, pressure, and direction in a system. They come in several types, including globe, ball, and gate valves. Each type serves distinct functions and has unique advantages. Making the correct choice requires careful consideration of your project's specific needs and operational conditions. However, many overlook essential factors like material compatibility, pressure ratings, and flow characteristics.

There are no one-size-fits-all solutions in the world of flow control valves. Improper selections can lead to inefficient operation and costly downtime. For instance, a valve with the wrong flow rate might not provide adequate performance. Therefore, it’s vital to analyze each application's requirements meticulously. Taking the time to understand these nuances can help ensure optimal performance of flow control valves in any system.

Flow control valves are essential in various industries. They manage fluid flow, ensuring processes run smoothly. Different types of valves fit different applications. Knowing these types is crucial for selecting the right one.

One common type is the globe valve. These valves regulate flow through a spherical body. They work well for throttling service. Another type is the ball valve. With a simple quarter-turn motion, they offer quick shut-off. They are ideal for on-off applications. However, sometimes users may underestimate their effectiveness in throttling.

Pressure relief valves are also important. They provide safety by preventing excessive pressure build-up. Yet, some systems might not require them for specific applications. This oversight can lead to failures. Each valve type has distinct features. Understanding these is vital for optimal performance. Take the time to analyze your system's needs before choosing a valve.

This chart illustrates the performance of different types of flow control valves based on their application efficiency and flow rate capacities. The data represents commonly used valve types: Needle Valve, Ball Valve, Gate Valve, and Butterfly Valve.

Selecting the right flow control valves for industrial applications can be a complex task. Key factors to consider include the type of fluid, flow rate, and pressure conditions. According to recent industry reports, over 40% of valve failures result from improper selection. This statistic highlights the need for thorough analysis and understanding of fluid dynamics in specific applications.

Another important aspect is the valve's material compatibility with the fluid being controlled. Corrosion and wear can significantly impair performance. A study found that 30% of valve issues stemmed from material degradation. It's crucial to select materials that withstand the operational environment to enhance longevity.

Attention must also be given to the valve's sizing. An undersized valve can lead to unwanted pressure drops. Conversely, oversized valves may lead to inefficiencies. Data shows that incorrect sizing can waste up to 20% of energy in a system. This inefficiency can translate to substantial costs over time. Proper evaluation and understanding of the system's requirements can mitigate these risks.

When selecting flow control valves, size and capacity play critical roles in ensuring optimal performance. Valves must match the flow requirements of a system. A valve that is too small can lead to pressure build-up. Conversely, an oversized valve can cause flow instability. Striking a balance is essential for efficiency.

Always consider the specific application. For instance, a high-viscosity fluid may require a different valve size than a low-viscosity one. Conduct thorough calculations to find the right size for your needs. Running simulations can also help avoid miscalculations. Keep in mind that installation impacts performance too. Misaligned valves can lead to leaks and reduced efficiency.

Tips: Keep it simple. Regular maintenance checks can help identify issues early. Don’t overlook the importance of proper training for staff handling these valves. They should understand the implications of size and capacity. Lastly, size isn't everything. It’s crucial to evaluate other factors such as pressure drop and flow rate. Test various configurations to find what works best for your system.

Material selection plays a crucial role in the performance of flow control valves. The right material can enhance durability. It can also improve resistance to corrosion and wear. Common materials include stainless steel, brass, and thermoplastics. Each offers unique benefits and limitations.

Stainless steel is known for its strength. However, it may not be suitable for all fluids. Brass is often used for its machinability and natural anti-corrosive properties. Yet, it may degrade under certain conditions. Thermoplastics are lightweight and resistant to chemicals. Their flexibility can be advantageous but may limit pressure ratings.

Choosing the right material requires careful consideration. Think about fluid types and environmental conditions. Reflect on how different materials may affect long-term performance. Each option has trade-offs. The ideal choice often lies in balancing these factors effectively. Selecting materials isn’t just about cost. It’s about ensuring reliability and functionality in real-world applications.

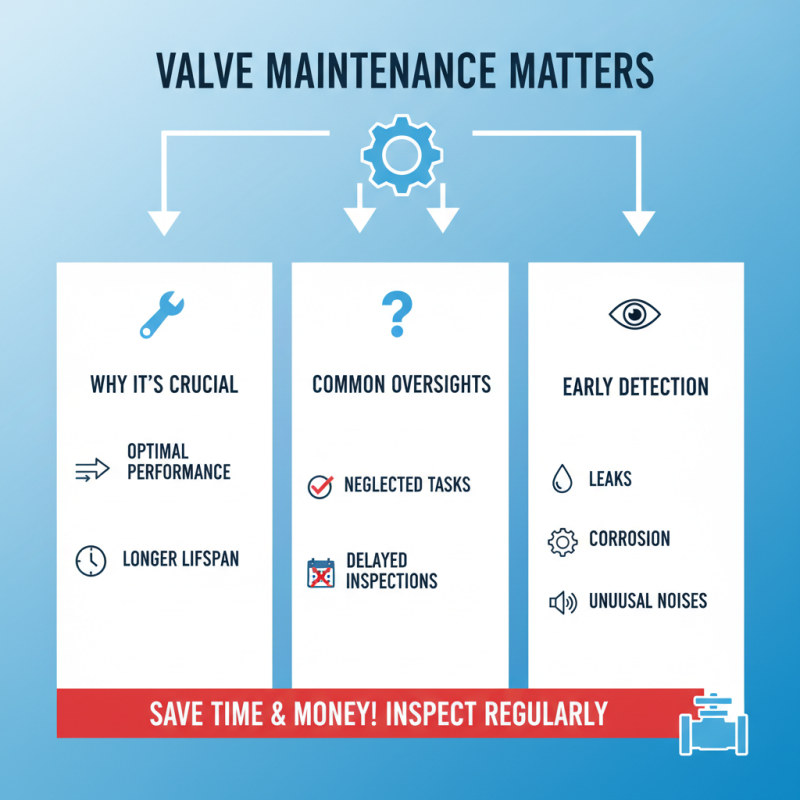

Regular maintenance is crucial for valve functionality. Often, users overlook simple tasks. This can lead to performance issues. Inspecting flow control valves regularly helps identify problems early. Look for leaks, corrosion, and unusual noises. These signs often hint at underlying issues.

Cleaning is another essential aspect. Dirt buildup can impede performance. Use appropriate cleaning solutions to keep valves in optimal condition. Sometimes, users are reluctant to replace old parts. This may save money, but it can compromise efficiency. Regularly check fittings and seals for wear. They may need replacement sooner than expected.

Testing valves under different conditions is beneficial. Observe how they respond to changes. This can uncover flaws that routine checks might miss. Documenting performance over time also helps spot trends. Don't hesitate to revisit malfunctioning valves. Sometimes, a fresh perspective reveals what has been overlooked. Adjustments may be necessary. Waiting too long can lead to bigger issues down the road.