Leave Your Message

Choosing the right Directional Logic Element Valves for your project can be challenging. According to James Smith, an industry expert, "Not all valves are created equal." His insight highlights the importance of understanding specific needs. Directional Logic Element Valves are crucial in directing fluid flow in hydraulic systems.

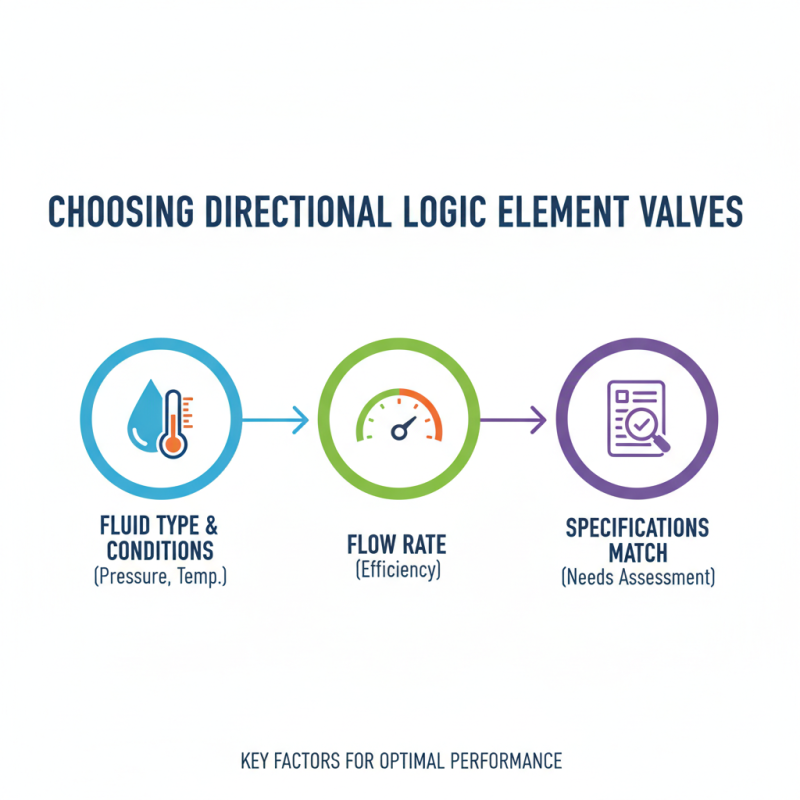

When selecting these valves, consider factors such as pressure ratings, flow capacity, and response time. Sometimes options can overwhelm you, leading to indecision. Each application may require different specifications that are not immediately clear. Understanding the nuances is key.

Many engineers overlook the need for compatibility with existing systems. This oversight can result in costly modifications. Taking time to reflect on your project’s requirements is essential. You want the best performance, and that starts with the right Directional Logic Element Valves. Don’t rush; make an informed choice.

Directional logic element valves play a vital role in various hydraulic and pneumatic systems. Understanding their function is crucial for effective project implementation. These valves control the flow and direction of fluids, impacting efficiency and performance. According to industry reports, proper valve selection can improve system efficiency by up to 30%. Knowledge of valve types and configurations is key to making informed choices.

When selecting directional valves, consider the application requirements. Factors such as pressure, flow rate, and medium type are essential. Each project demands a unique setup, and a one-size-fits-all approach may lead to inefficiencies. An improper valve choice can result in increased energy consumption and maintenance costs. Remember, even small miscalculations can affect performance.

**Tips:** Ensure you evaluate both the operating environment and the required response times. A thorough analysis can prevent costly mistakes. Collaborate with experts to optimize your choices. Additionally, look into maintenance practices from the outset. Regular checks can extend the life of your valves and enhance system reliability.

When choosing directional logic element valves for your project, there are several key factors to keep in mind. Understand the fluid type that will flow through the valve. Different fluids exert various pressures and temperatures. This directly affects valve performance. Also, consider the flow rate required for your application. An incorrect flow rate can lead to inefficiency. Look for specifications that match your needs.

Another important factor is the valve's material. Valves made from different materials perform differently under various conditions. Corrosion resistance can be critical. Think about the environment where the valve will operate. In some cases, a quick installation may be necessary, but this can sometimes lead to oversights. Ensure that all connections are secure to avoid leaks.

Evaluate the control method as well. Valves can be manually operated or automated. Each has its pros and cons. Automation can increase efficiency, but may add complexity. This could lead to maintenance challenges. A clear analysis of your project's requirements will guide your decision-making process and might reveal unexpected needs.

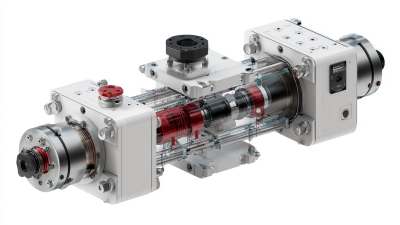

When selecting directional logic element valves, understanding the differences is crucial. There are typically three types: solenoid, pneumatic, and hydraulic valves. Solenoid valves are popular for their ease of use and rapid response times. They require electrical energy to operate, making them suitable for automated systems. However, they may not handle high flow rates as efficiently as other options.

Pneumatic valves, on the other hand, utilize compressed air. They are fast and reliable, ideal for applications requiring quick actuation. However, their performance can suffer in environments with fluctuating air pressure. Hydraulic valves operate using liquid fluids, offering high force capabilities. Yet, they may require more complex systems, leading to potential maintenance issues.

Choosing the right valve involves considering not only the application but also space constraints and environmental factors. A poorly chosen valve can lead to inefficiencies or even system failures. It's essential to evaluate the specific requirements of your project. Each type has its pros and cons, and the best choice might not always be the most obvious one. Reflect on the long-term needs and potential shortcomings of any valve type you consider.

This chart compares different types of directional logic element valves based on their flow rates, pressure ratings, and estimated costs. The data is intended to help you make an informed decision for your project.

Directional logic element valves are crucial in fluid power systems. However, they can face common issues. Understanding these problems helps ensure your project runs smoothly.

One common issue is leaking, which usually indicates worn seals. Inspect the seals regularly to identify potential failures early. Another issue can arise from sticking valves. Contaminants or worn-out parts may lead to this. Regular maintenance is vital. Keep the valve clean and replace parts when needed.

**Tips:**

- Always use the correct fluid. Wrong types can cause damage.

- Store valves properly when not in use. This prevents contamination.

- Test the system after installation to catch mistakes early.

Over time, installation mistakes can become apparent. A valve may seem to work fine initially but fail under pressure. This emphasizes the need for a thorough review of your setup. Take a moment to evaluate every connection and fitting. Errors can be costly later.

| Criteria | Description | Common Issues | Solutions |

|---|---|---|---|

| Valve Type | Choosing the proper valve type (e.g., solenoid, pneumatic) based on the application. | Incorrect valve selection leading to inefficiency. | Evaluate duty requirements and process conditions to ensure compatibility. |

| Flow Rate | Rate of fluid passing through the valve under normal operating conditions. | Low or high flow rate causing system pressure issues. | Calculate required flow rate accurately for optimal performance. |

| Pressure Rating | Maximum pressure the valve can withstand. | Valve failure due to excessive pressure. | Select valves with pressure ratings above maximum system pressure. |

| Material Compatibility | Ensuring materials are resistant to the substances handled. | Corrosion or degradation of valve materials. | Use materials that are chemically compatible with the fluid or gas. |

| Installation Space | Available physical space for valve installation. | Space constraints making installation difficult. | Choose compact designs or install in a way that maximizes space. |

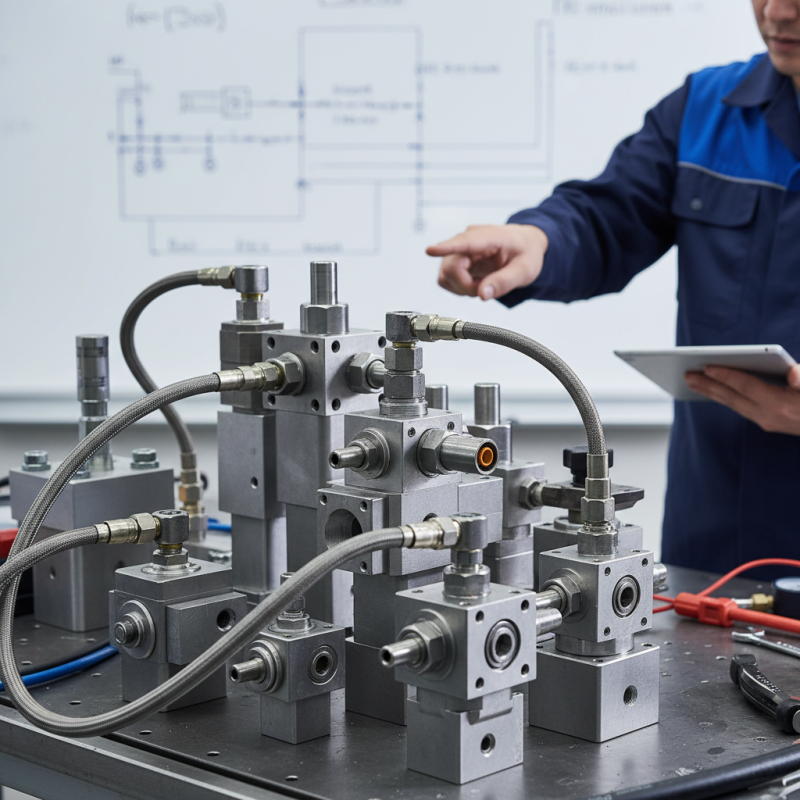

When installing directional logic element valves, attention to detail is crucial. Start with a clean workspace to prevent contamination. Ensure all tools are ready. An overlooked detail can cause issues later. It's wise to follow manufacturer guidelines closely. They provide essential insights specific to the valve type. However, adapt techniques to your unique project needs.

During maintenance, regularly check for leaks and unusual noises. These signs can indicate a problem. A small leak might seem minor, but it can lead to bigger issues. Schedule routine inspections to catch problems early. Keep a log of maintenance activities. This helps identify patterns over time. Reflecting on past maintenance can reveal effective practices. Encourage team members to share their observations.细节 matters.