Leave Your Message

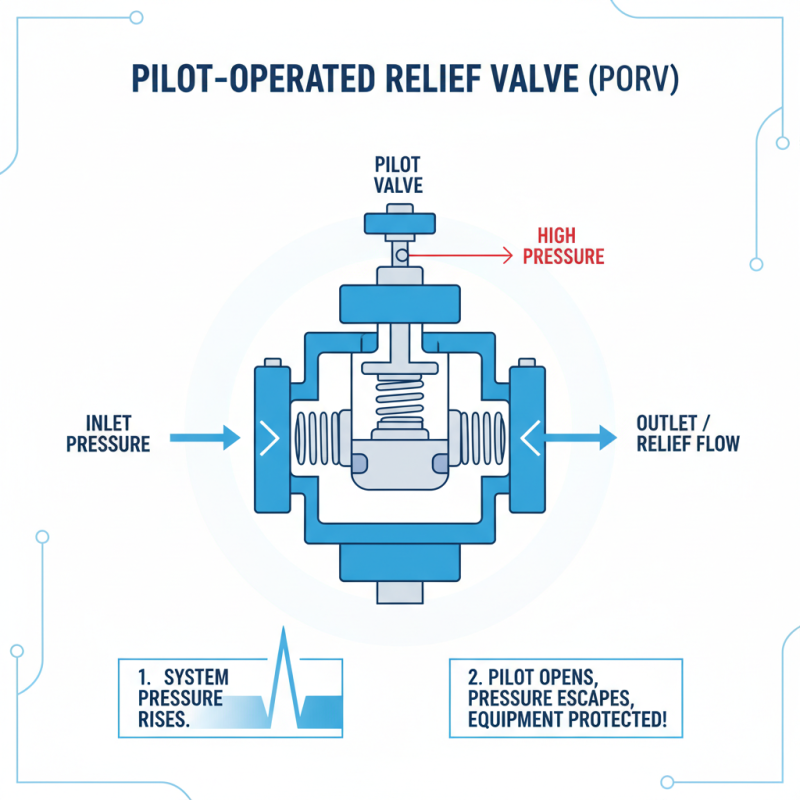

In many industrial applications, system efficiency and safety are paramount. One crucial component that plays a significant role is the Pilot Operated Relief Valve (PORV). According to industry reports, over 25% of pressure system failures can be attributed to inadequate pressure control. A reliable pressure relief valve is essential to prevent catastrophic failures and ensure operational stability.

Pilot Operated Relief Valves are designed to offer enhanced precision in pressure regulation. This technology allows for a quicker response to changes in system pressure, reducing the risk of overpressure situations. A study by the Fluid Power Journal found that systems utilizing PORVs reduce pressure fluctuation by up to 30%. This remarkable efficiency translates to improved system performance and lower maintenance costs over time.

While PORVs have their advantages, they are not without challenges. For instance, the complexity of these valves can lead to misinterpretations during installation and maintenance. Additionally, the requirement for a stable pilot signal might not be feasible for all systems. Evaluating whether a Pilot Operated Relief Valve aligns with your system requirements is crucial for maximizing both safety and productivity.

Pilot operated relief valves are essential components in many systems. They offer a reliable solution to pressure control. Understanding their design and function can improve system safety and efficiency.

These valves utilize a pilot valve to control the main valve. When system pressure exceeds a set limit, the pilot opens. This action allows fluid to flow and relieves excess pressure. The design is compact, which makes installation easier. However, not every system may need this complexity. Some systems may function well with simpler solutions.

The effectiveness of a pilot operated relief valve depends on its sizing and application. Proper selection is crucial to prevent failures. Regular maintenance checks can ensure that the valve performs optimally. Over time, sediment and debris can hinder its operation. Without proper attention, the valve may not open as intended. This can lead to dangerous pressure buildup. Thus, an understanding of their role is key.

When selecting a relief valve for your system, pilot operated relief valves stand out. Their design enhances efficiency by responding quickly to pressure changes. This helps maintain system stability. They often have a larger flow capacity compared to conventional relief valves. This makes them suitable for high-demand applications.

One significant advantage is their ability to provide precise pressure control. They can handle larger variations without sacrificing performance. This can lead to improved safety in your system. However, it’s critical to ensure proper installation. Poor installation can negate these benefits.

**Tip:** Regular maintenance checks can prevent unexpected failures. Monitor the valve performance closely. If you notice fluctuating pressure, it might be time to look deeper into your system’s configuration.

Pilot operated valves can also manage varying fluid characteristics effectively. However, be cautious about the fluid’s temperature and viscosity. These factors can affect valve performance. A mismatch can lead to inefficiencies and higher operational costs.

**Tip:** Keep records of operational data. This can help identify trends and potential issues. Adjustments based on historical performance can enhance reliability.

Pilot operated relief valves (PORVs) are crucial for maintaining system safety. They utilize hydraulic pressure to manage flow. When the pressure exceeds a predetermined limit, the pilot valve opens. This action allows excess pressure to escape. Consequently, it protects downstream equipment from damage.

According to industry reports, PORVs are efficient, with a flow capacity increased by up to 50% compared to standard relief valves. This efficiency results from their unique design. However, not every system benefits equally from this technology. In some cases, improper installation can lead to significant leaks. This reality is a concern for maintenance teams.

Many engineers overlook the need for routine checks on PORVs. In fact, a study indicated that about 30% of relief valves in the field were found to be inoperable. Regular testing can help mitigate this risk. Despite their advantages, complacency can lead to disasters. Understanding how these valves function is essential for safe operation.

Pilot operated relief valves are widely used in various industries due to their efficiency and reliability. These valves are crucial in hydraulic systems, ensuring safe operation under fluctuating pressures. In manufacturing, they help maintain optimal pressure levels in hydraulic presses. This application prevents over-pressurization, which can lead to catastrophic failures.

In the oil and gas sector, pilot operated relief valves are vital. They regulate pressure in pipelines and tanks, preventing leaks and potential explosions. Additionally, these valves are found in water treatment facilities. They manage pressure in water distribution systems, which is essential for maintaining service efficiency.

However, they are not without challenges. Proper selection and installation are crucial, and mistakes can occur. An improperly sized valve can lead to pressure spikes or drops. Regular maintenance is also necessary, as wear and tear can affect performance. Addressing these factors is key for optimal functionality.

Pilot operated relief valves are crucial in many systems. However, maintenance plays a key role in their performance. Regular checks can prevent serious issues. Neglect might lead to valve failure or system damage.

Tips for maintenance: Inspect the valves regularly. Listen for unusual sounds during operation. Check for leaks around seals and connections. A small leak can indicate a larger issue. Ensure the pilot line is clear and free of debris. This is essential for proper function.

In some cases, you may find that the valve opens at an incorrect pressure. This might happen due to dirt buildup. Cleaning the valve regularly can help maintain accuracy. Remember, regular servicing can save time and costs later. It’s an investment in your system’s reliability.

| Dimension | Description | Importance |

|---|---|---|

| Set Pressure | The pressure at which the valve will open to relieve excess pressure. | Critical for system safety and preventing overpressure conditions. |

| Response Time | The time it takes for the valve to respond to overpressure by opening. | Essential for timely pressure relief and protection of equipment. |

| Maintenance Interval | Recommended frequency for inspecting and servicing the valve. | Helps ensure reliable operation and prolongs lifespan of the valve. |

| Material Compatibility | Suitability of valve materials for the fluids being handled. | Prevents corrosion and failure, ensuring safety in operation. |

| Size and Capacity | Physical size of the valve and its flow capacity. | Important for ensuring proper sizing for fluid dynamics in the system. |