Leave Your Message

In the realm of hydraulic systems, the selection of Stacked Counterbalance Valves is crucial for optimizing performance and ensuring system efficiency. As the demand for advanced hydraulic solutions increases, industry reports indicate that the global market for counterbalance valves is projected to grow at a CAGR of 5.8% from 2023 to 2028. This growth underscores the necessity for engineers and manufacturers to make informed choices to meet their operational needs effectively.

According to renowned hydraulic systems expert, Dr. John Smith, “Choosing the right Stacked Counterbalance Valves can significantly impact system stability and efficiency.” Dr. Smith's insights highlight the importance of understanding the specific applications and requirements when selecting these valves. The right valve not only enhances safety but also contributes to longer equipment life and reduced maintenance costs.

As we dive into the intricacies of Stacked Counterbalance Valves, this guide will provide essential tips and considerations to help professionals navigate the selection process. By leveraging industry data and expert opinions, we aim to equip you with the knowledge necessary to make the best decisions tailored to your unique needs.

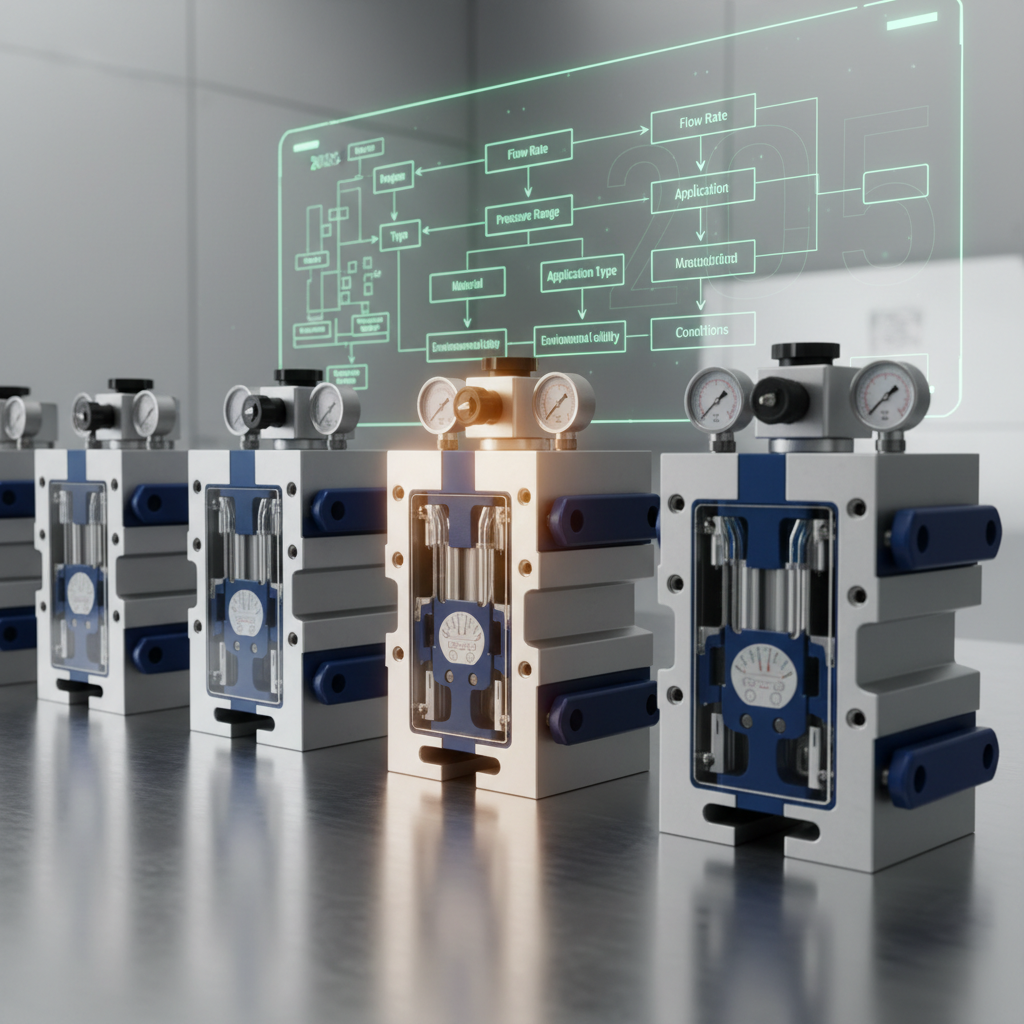

When selecting stacked counterbalance valves, several key considerations can significantly impact performance and efficiency. According to the International Journal of Fluid Power, the design and quality of counterbalance valves are critical in managing load control and preventing uncontrolled motion in hydraulic systems. An optimal valve must seamlessly integrate with existing hydraulic circuitry, ensuring minimal pressure drops and voltage fluctuations. Studies indicate that improperly selected valves can lead to a decrease in system efficiency by up to 30%, emphasizing the importance of selecting valves with appropriate flow rates and response times for specific applications.

Another vital aspect is compatibility with the hydraulic fluid and temperature ranges. For instance, reports from the Hydraulic Institute suggest that counterbalance valves must withstand various environmental conditions to ensure longevity and reliability. It is essential to assess the maximum operating pressure and flow characteristics of both the valve and the overall hydraulic setup. Evaluating these parameters helps prevent premature wear and failure. Industry experts recommend selecting valves from reputable manufacturers that provide data on product performance, thereby enhancing the reliability and efficiency of hydraulic systems in diverse applications.

| Parameter | Description | Importance | Recommended Value |

|---|---|---|---|

| Flow Capacity | Maximum flow rate that can be handled by the valve. | High | 20-100 L/min |

| Pressure Rating | Maximum pressure that the valve can withstand without failure. | High | 70-350 bar |

| Response Time | Time taken for the valve to respond to input signals. | Medium | <1 ms |

| Temperature Range | Operating temperature range of the valve. | Medium | -20°C to 80°C |

| Mounting Type | Type of mounting compatible with the valve. | Low | Stacked, Inline |

| Weight | Total weight of the valve assembly. | Low | 5-10 kg |

When selecting the best stacked counterbalance valves for specific applications, understanding the different types available is crucial. Stacked counterbalance valves are designed to control the motion of hydraulic cylinders effectively, preventing uncontrolled descent and ensuring stability. A notable report from the International Fluid Power Society (IFPS) indicates that over 60% of hydraulic system failures can be traced back to improper valve selection, highlighting the importance of choosing the right type for optimal performance.

There are primarily two types of stacked counterbalance valves: pilot-operated and direct-acting valves. Pilot-operated valves are typically used in high-flow applications where precise control is paramount. They utilize a pilot pressure to assist in opening the main flow path, allowing for smoother operation under varying load conditions.

On the other hand, direct-acting valves are advantageous in low-flow or static applications, where they offer quicker response times and lower manufacturing costs. According to hydraulic industry analysis by the National Fluid Power Association (NFPA), the preference for pilot-operated valves has increased by 25% in the last five years, driven by advancements in automation and the rise of more sophisticated hydraulic systems.

Understanding the specific demands of your hydraulic system will guide you in selecting the most suitable type of stacked counterbalance valve.

When choosing the best stacked counterbalance valves for your needs, it's crucial to evaluate the flow and pressure ratings specific to your application. These ratings not only influence the performance of hydraulic systems but also ensure safety and efficiency under varying operating conditions. Recent industry reports indicate that improperly rated valves can lead to significant performance failures, costing companies both time and money. Therefore, understanding your application's requirements is essential in making an informed decision.

Tips: Always refer to the specific flow requirements for your machinery. For instance, a typical hydraulic system might require a flow rate of 10 to 30 liters per minute, while high-performance systems can exceed these figures. Ensuring your valve can handle the maximum pressure required—often around 200 bar or more for industrial applications—will help mitigate risks.

Additionally, consider that the temperature range of your application can affect valve performance. Many valves are rated for temperatures between -20°C and 80°C, but extreme cases may require specialized products. Investing time in understanding these parameters will greatly enhance your system's reliability and longevity.

When selecting the best stacked counterbalance valves for your needs, it is crucial to evaluate the features offered by different manufacturers. Each manufacturer brings unique innovations and technologies that can significantly impact performance and efficiency. For instance, some brands may provide advanced pressure modulation capabilities, while others might excel in response times or hydraulic fluid compatibility. Understanding these features allows you to align product specifications with your operational requirements.

Equally important is assessing the product reliability of various manufacturers. A reliable counterbalance valve not only minimizes downtime but also enhances the overall safety and performance of your hydraulic systems. Investigating customer reviews, case studies, and warranty offerings can provide insights into the durability and long-term performance of the valves. Choosing a manufacturer with a proven track record in reliability ensures that you invest in a product that meets your expectations and withstands the rigors of everyday use. By carefully comparing these elements, you can make a well-informed decision that suits your specific needs in hydraulic applications.

When considering stacked counterbalance valves, budget is often a primary concern. Understanding the cost differences between budget-friendly options and premium choices is crucial for making the right decision.

Budget-friendly valves typically offer basic features and durability, making them suitable for applications with lower pressures and lighter loads. These options can be a sensible choice for small businesses or projects with limited financial resources, helping to keep costs down while still providing necessary functionality.

On the other hand, premium options generally come equipped with advanced features such as improved flow control, enhanced materials, and superior engineering. These valves are designed to withstand higher pressures and heavier loads, making them ideal for more demanding industrial applications. Although the initial investment is higher, choosing a premium stacked counterbalance valve can lead to long-term savings through increased efficiency and reduced maintenance costs. It is essential to evaluate the specific requirements of your applications and consider both short-term costs and long-term benefits before making a decision.