Leave Your Message

In the intricate world of hydraulic systems, the selection and effective utilization of a Bidirectional Relief Valve is crucial. As renowned industry expert Dr. Emily Choi, a leading fluid dynamics researcher, states, “Understanding the specific requirements of your system is essential when integrating a Bidirectional Relief Valve—its efficiency can significantly enhance system performance.” This underscores the importance of not only choosing the right component but also ensuring it works harmoniously within the overall system design.

A Bidirectional Relief Valve serves as a vital component in preventing over-pressurization, allowing for safe operation in both directions of fluid flow. Its ability to accommodate varying pressures ensures that hydraulic systems function efficiently while safeguarding against potential damage. However, selecting the appropriate valve requires a thorough understanding of the system’s operational parameters, including pressure ratings, flow characteristics, and installation requirements.

In this context, this article aims to provide a comprehensive guide on how to best choose and use a Bidirectional Relief Valve in your system, highlighting key factors to consider during the selection process and offering practical tips for optimal installation and maintenance. By following these guidelines, engineers and technicians can enhance the reliability and efficiency of their hydraulic systems, ultimately leading to superior operational outcomes.

Bidirectional relief valves play a crucial role in systems requiring pressure regulation, particularly in hydraulic and pneumatic applications. These valves are designed to allow fluid to flow in both directions while providing a reliable means to relieve excess pressure, preventing potential damage to the system. According to a report by the International Hydraulics Association, nearly 30% of system failures can be traced back to inadequate pressure control, underscoring the importance of selecting the right relief valve for efficient operation.

Utilizing a bidirectional relief valve effectively requires a solid understanding of its functionality and the conditions under which it operates. These valves are engineered to handle backpressure while ensuring that the system remains stable during variations in pressure loads. When installing a bidirectional relief valve, consider the specific flow rate requirements and the maximum allowable pressure in the system, as these factors can significantly impact performance.

Tips: When choosing a bidirectional relief valve, always consult system specifications to ensure compatibility. Additionally, routine maintenance checks are recommended to avoid any performance issues. Monitoring pressure fluctuations and maintaining the valve's operational integrity can lead to improved system efficiency and reduced downtime, as highlighted in recent industry analysis reports.

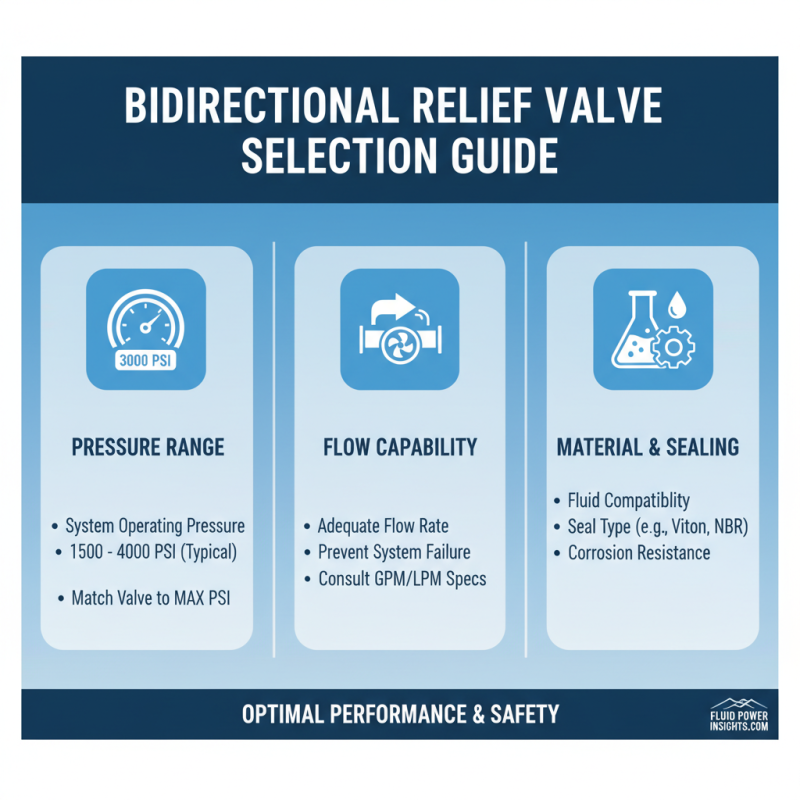

When selecting a bidirectional relief valve for your system, several key factors must be taken into account to ensure optimal performance and safety. First and foremost, understanding the pressure range of your system is critical. According to a report by the Fluid Power Distributors Association, the majority of hydraulic systems operate between 1500 to 4000 PSI. Therefore, selecting a valve that can handle the maximum expected pressure while providing adequate flow capability is essential for preventing system failures.

Another important consideration is the valve's material and size. Industry standards indicate that materials must be compatible with the fluids being handled, particularly in high-corrosion environments, where stainless steel or specialized alloys may be required. Additionally, the sizing of the valve is crucial; it must match the flow requirements of your system to avoid cavitation or inadequate flow, which can compromise functionality. A sizing guideline published in the Journal of Hydraulic Engineering suggests consulting flow charts to properly match valve sizes with system demands for efficiency and reliability.

Lastly, it's important to assess the installation and maintenance requirements of the relief valve. A comprehensive study conducted by the International Fluid Power Society indicates that improper installation can lead to up to 30% reduction in valve performance. Regular maintenance checks and ease of access can also prolong the life of the valve, ensuring that the system operates smoothly and safely over time.

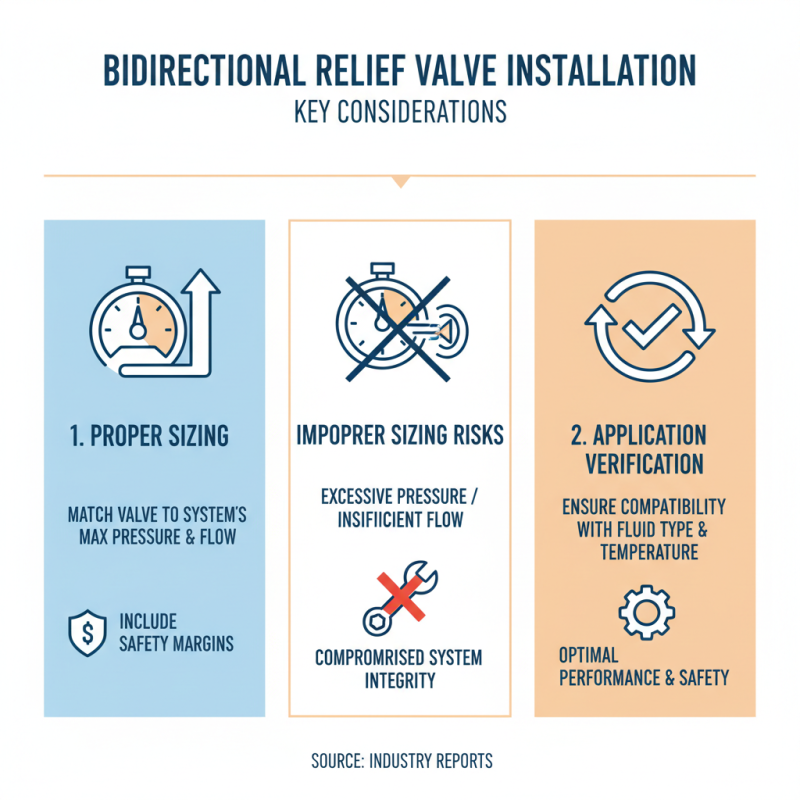

When installing a bidirectional relief valve in your system, several key factors should be considered to ensure optimal performance and safety. One of the primary guidelines is to verify that the valve is adequately sized for your application. According to industry reports, improper sizing can lead to either excessive pressure buildup or insufficient flow capacity, which can compromise system integrity. The relief valve should be selected based on the system's maximum expected pressure and flow, taking into account safety margins to accommodate any potential pressure surges.

Additionally, the installation location is critical. The bidirectional relief valve should be positioned in a way that minimizes the chances of fluid entrapment and ensures it can operate effectively when required. This often means installing the valve at the highest point in the system or in a location where backpressure is minimal. According to a study by the Fluid Power Society, improper installation can lead to operational failures in up to 25% of hydraulic systems. Proper orientation and securing the valve can also prevent leakage and ensure it operates within the intended pressure range, contributing to overall system reliability.

Maintaining and testing bidirectional relief valves is crucial to ensure the safety and efficiency of hydraulic systems. Regular maintenance should begin with visual inspections to check for any signs of leakage, corrosion, or physical damage. It's essential to clean the valves periodically, as contaminants can lead to malfunction.

Operators should also verify that the valve operates smoothly and responds appropriately to changes in pressure. A well-maintained valve not only prolongs its lifespan but also enhances the overall reliability of the system.

Testing bidirectional relief valves involves both functional and performance checks. A pressure test should be conducted to confirm that the valve opens at the specified set pressure and shuts properly. Additionally, operators should assess the relief capacity to ensure it meets system requirements.

Utilizing hydrostatic testing can be beneficial in identifying any weaknesses that may not be visually detectable. By documenting test results and maintenance activities, operators can better track the performance of the valves and anticipate future maintenance needs. Regular testing and thorough documentation are key practices that ensure optimal operation and system safety.

Bidirectional relief valves play a crucial role in various industries, providing crucial protection for systems operating under pressure. In hydraulic systems, for instance, these valves are employed to manage excess pressure from two directions, ensuring that operations remain safe and efficient. According to a recent report by the International Society for Automation, over 30% of hydraulic system failures can be attributed to pressure imbalances, highlighting the importance of integrating bidirectional relief valves into system designs to prevent costly downtime.

In the oil and gas industry, bidirectional relief valves are essential for managing pressure during drilling and production operations. Their application minimizes the risk of blowouts, which can be both dangerous and financially damaging. A study by the American Petroleum Institute indicates that effective pressure management through the use of relief valves can reduce operational risks by as much as 25%. Furthermore, they are commonly used in pharmaceutical manufacturing where maintaining precise pressure levels is vital for product integrity and compliance with safety standards. These valves help ensure that excess pressure is safely redirected, thereby safeguarding both the systems and the products being developed.

Overall, the adoption of bidirectional relief valves across various sectors not only enhances operational security but also contributes to long-term cost savings and regulatory compliance. The versatility and reliability of these components make them indispensable in safeguarding high-pressure systems against potential hazards.