Leave Your Message

In today's competitive industrial landscape, maintaining optimal system performance is pivotal, and a crucial component in achieving this is the Bidirectional Relief Valve (BRV). According to a recent report by the Hydraulic Institute, improper pressure regulation can lead to operational inefficiencies costing businesses up to 30% of their overall productivity. The BRV plays a vital role in hydraulic and pneumatic systems by allowing controlled fluid movement in both directions, preventing potential operational hazards and enhancing safety protocols.

With the global hydraulic valve market projected to reach $11 billion by 2025, understanding the intricacies of Bidirectional Relief Valves is not merely beneficial but essential for engineers and system designers. This guide delves deep into the mechanics, applications, and advantages of BRVs, ensuring you can harness their full potential for superior system performance.

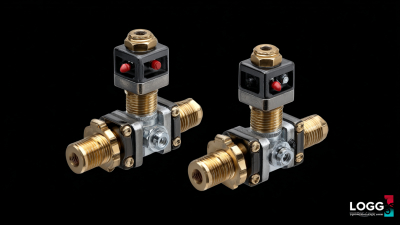

Bidirectional relief valves are essential components in hydraulic and pneumatic systems, designed to maintain optimal pressure levels and ensure system safety. One of the key features of these valves is their ability to provide pressure relief in both directions. This characteristic allows for greater system flexibility, accommodating fluctuations in flow and pressure that can occur in complex operational scenarios. By preventing pressure build-up in either direction, these valves not only protect equipment from potential damage but also enhance overall system reliability.

Another significant feature is the precision engineering involved in the design of bidirectional relief valves. Advanced materials and manufacturing techniques contribute to their durability and responsiveness. Many models come equipped with adjustable settings, allowing operators to fine-tune pressure levels according to specific operational requirements. Additionally, the integrated design often includes features like built-in dampening mechanisms, which help reduce noise and vibrations during operation. This attention to detail not only improves system performance but also extends the lifespan of other components within the system.

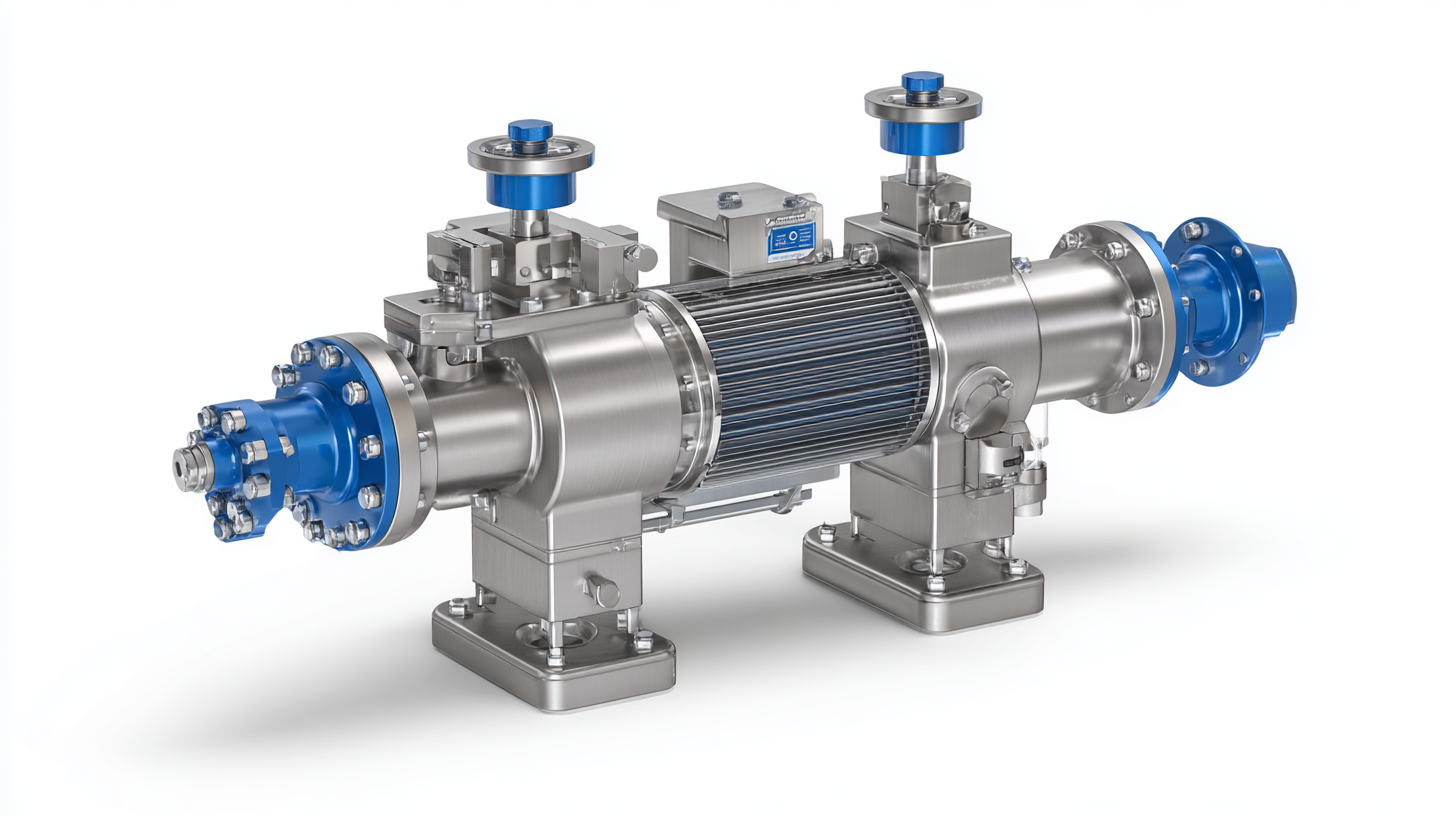

Bidirectional relief valves play a pivotal role in various fluid systems, ensuring optimal performance by managing excess pressure in both directions. These valves are widely utilized in sectors such as hydraulics, oil and gas, and water treatment. According to a report by MarketsandMarkets, the global market for relief valves is projected to reach $4.2 billion by 2026, primarily driven by growing industrialization and the increasing need for safety in fluid handling systems.

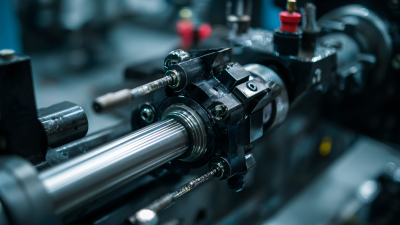

In hydraulic systems, bidirectional relief valves are critical for preventing damage due to overpressure, particularly in applications involving heavy machinery and equipment. The ability of these valves to discharge fluid in both directions allows for improved pressure regulation, significantly enhancing system efficiency. Furthermore, the International Fluid Power Society indicates that proper valve selection and placement can increase system reliability by up to 30%, reflecting the importance of these components in maintaining operational integrity.

Moreover, in the oil and gas industry, bidirectional relief valves are essential for managing pressure fluctuations during extraction and transportation. A study from the American Society of Mechanical Engineers (ASME) highlights that the implementation of advanced relief valves can reduce incidents related to pressure surge by 40%, ultimately promoting safer and more efficient operations. This underscores the importance of integrating high-quality bidirectional relief valves into fluid systems for optimal performance and safety.

Bidirectional relief valves play a crucial role in maintaining optimal system performance by preventing overpressure scenarios in hydraulic and pneumatic systems. Proper installation and maintenance of these valves are essential to ensure their reliable operation. According to a recent industry report from the Fluid Power Society, nearly 20% of equipment failures can be traced back to improperly installed or maintained relief valves. Consequently, following the manufacturer's guidelines during installation is imperative.

To achieve optimal performance, it's recommended to regularly inspect relief valve settings and functionality. The American Society of Mechanical Engineers (ASME) suggests that pressure relief valves should undergo functional testing at least once a year. This ensures that the valves will open at the designated pressure, thus preventing system failures. Additionally, keeping the valve clean and free from contaminants significantly extends its lifespan, which is a crucial aspect highlighted in industry maintenance manuals. By adhering to these practices, operators can minimize downtime and enhance the efficiency of their systems, ultimately leading to superior performance and reliability.

| Parameter | Description | Importance | Maintenance Tips |

|---|---|---|---|

| Pressure Rating | The maximum pressure that the valve can withstand | Ensures the system operates safely within limits | Regularly check for leaks and pressure anomalies |

| Flow Rate | The amount of fluid that can pass through the valve | Critical for system efficiency and performance | Inspect for blockages and clean regularly |

| Temperature Tolerance | The range of temperatures the valve can operate under | Prevents valve malfunction due to thermal expansion | Monitor temperature and replace if necessary |

| Material | The substance from which the valve is made | Affects durability and corrosion resistance | Inspect for signs of wear and replace aging materials |

| Type of Actuation | Manual, pneumatic, or electric actuation method | Determines responsiveness and control precision | Regularly test actuation mechanism functionality |

When selecting the right bidirectional relief valve for your system needs, it is essential to begin with a clear understanding of your system's specific requirements. The operating pressure range will significantly influence your choice; ensure the valve can handle both the maximum system pressure and any potential surges. Additionally, consider the type of fluid being used, as compatibility is crucial for maintaining valve integrity and ensuring optimal functionality.

When selecting the right bidirectional relief valve for your system needs, it is essential to begin with a clear understanding of your system's specific requirements. The operating pressure range will significantly influence your choice; ensure the valve can handle both the maximum system pressure and any potential surges. Additionally, consider the type of fluid being used, as compatibility is crucial for maintaining valve integrity and ensuring optimal functionality.

Another important factor is the valve's response time and flow capacity. A valve that opens too slowly may not adequately protect your system from pressure spikes, while one that is too large may introduce inefficiencies. Review the manufacturer's specifications to determine the ideal size and performance characteristics tailored to your application. Finally, you should assess installation and maintenance needs; some valves come with features that simplify these processes, ultimately contributing to improved system reliability and performance. By keeping these considerations in mind, you can confidently select a bidirectional relief valve that optimizes your system’s operation.

Bidirectional relief valves play a crucial role in managing pressure within fluid systems. Understanding their functionality is essential for optimizing operational efficiency and preventing system failures. These valves are designed to open and relieve pressure in both directions, ensuring that excess pressure is controlled effectively. By maintaining balanced pressure levels, they help mitigate risks associated with pressure surges that could potentially damage equipment or lead to undesirable operation conditions.

The efficiency of bidirectional relief valves is primarily determined by their design and the materials used in construction. Factors such as response time, flow capacity, and the ability to seal properly all contribute to how effectively a valve can manage pressure control. Insights into the mechanics of these valves reveal that a well-calibrated relief valve can significantly enhance system performance by reducing energy losses and ensuring that critical components operate under optimal conditions. Thus, selecting the right bidirectional relief valve becomes pivotal for achieving long-term reliability and efficiency in any pressure-controlled system.