Leave Your Message

In industrial applications, the management of pressure is crucial for ensuring operational safety and efficiency. Pressure Reducing Relief Valves (PRRVs) play a vital role in regulating pressure levels within systems, thereby preventing potential hazards associated with overpressure. According to a report by the International Society of Automation, improper pressure management is responsible for nearly 30% of industrial accidents, highlighting the importance of these valves in maintaining system integrity.

Expert John Smith, a leading authority in the field of pressure regulation technology, emphasizes the significance of PRRVs by stating, "The proper implementation of Pressure Reducing Relief Valves can significantly reduce the risk of catastrophic failures in industrial setups." The ability of PRRVs to adjust and stabilize pressure not only enhances safety but also optimizes operational efficiency, leading to reduced downtime and lower maintenance costs. As industries evolve and demand for safety and efficiency increases, the adoption of advanced pressure control technologies like PRRVs becomes essential for achieving sustainable and reliable operations.

Pressure reducing relief valves are essential components in industrial systems to ensure safety and efficiency. By regulating and reducing excess pressure within pipelines and vessels, these valves prevent potential catastrophes such as equipment failure, leaks, or explosions. Maintaining optimal pressure levels not only extends the lifespan of equipment but also ensures compliance with safety regulations, ultimately safeguarding both personnel and property.

When implementing pressure reducing relief valves, it is crucial to focus on maintenance and regular inspections. Here are some tips to keep in mind:

By integrating these valves effectively, industries can not only enhance safety but also improve operational reliability. The critical role of pressure reducing relief valves in risk mitigation cannot be overstated, making them indispensable in maintaining a safe working environment.

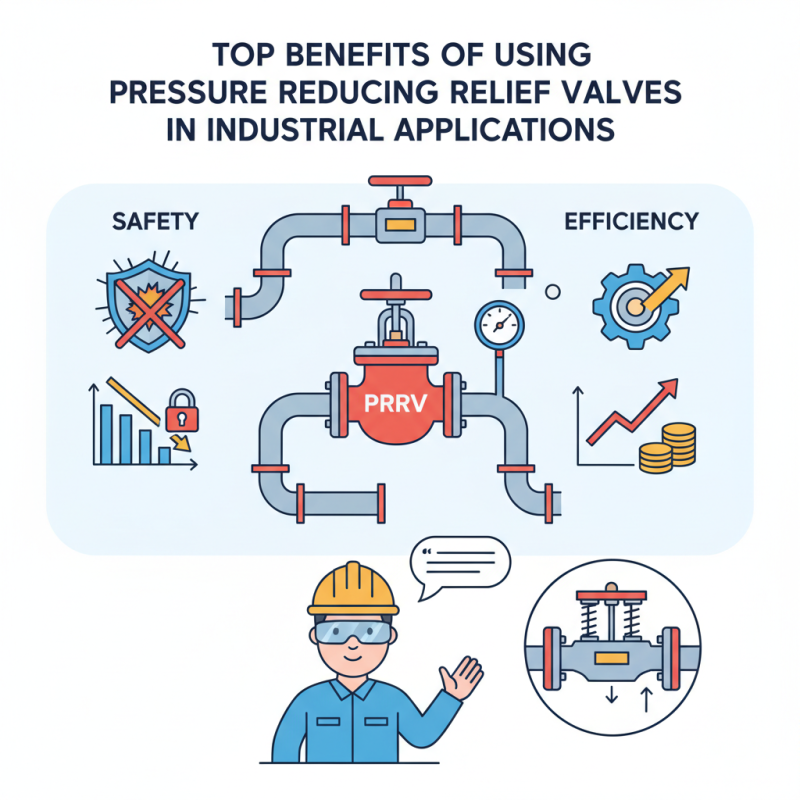

The implementation of pressure reducing relief valves (PRRVs) in industrial applications leads to significant efficiency improvements that optimize operations and enhance safety. By maintaining a consistent pressure level, these valves allow for precise control of fluid flow within various systems. This regulation minimizes pressure fluctuations that can result in equipment wear, leaks, and potential system failures, ultimately extending the lifespan of machinery and reducing maintenance costs.

Moreover, PRRVs play a crucial role in energy conservation. By ensuring that the pressure within systems does not exceed necessary levels, these valves help to prevent energy waste. Equipment can operate under optimal conditions, leading to lower operational costs and improved energy efficiency. Additionally, the ability to divert excess pressure effectively reduces the risk of catastrophic failures, creating safer working environments and allowing companies to focus on productivity rather than crisis management. Overall, the adoption of pressure reducing relief valves not only enhances operational efficiency but also contributes to the overall sustainability of industrial processes.

| Benefit | Description | Impact on Efficiency | Example Industry |

|---|---|---|---|

| Pressure Regulation | Maintains consistent downstream pressure | Reduces energy consumption by preventing over-pressurization | Oil and Gas |

| Safety Enhancement | Prevents sudden pressure spikes | Minimizes risk of equipment damage and failures | Chemical Processing |

| Operational Stability | Ensures steady operation under varying loads | Improves process reliability and reduces downtime | Manufacturing |

| Cost Reduction | Lowers maintenance and replacement costs | Results in long-term savings for facilities | Power Generation |

| Environmental Protection | Reduces emissions from over-pressured systems | Promotes compliance with environmental regulations | Pharmaceuticals |

In industrial applications, the integration of pressure reducing relief valves (PRRVs) significantly contributes to cost savings by minimizing system failures and downtime. According to a report by the International Society of Automation, system failure can lead to an average loss of $260,000 per incident for large operations. By regulating excessive pressure and maintaining system integrity, PRRVs help prevent catastrophic failures, thereby avoiding costly repair fees and production delays.

Moreover, consistent application of PRRVs has been shown to enhance operational efficiency. A study conducted by the International Journal of Pressure Vessel and Piping indicated that companies employing these valves experienced a 25% reduction in maintenance costs over five years due to decreased wear and tear on system components. This longevity not only extends the life of machinery but also diminishes the frequency of scheduled downtimes, aligning seamlessly with just-in-time production strategies.

Tips: To maximize the benefits of PRRVs, regularly assess system pressure levels and valve performance. Implementing routine inspections can help identify potential issues before they escalate, ensuring that your operations remain smooth and economic. Additionally, investing in quality training for personnel handling these valves can lead to better decision-making and proactive measures, ultimately leading to further reductions in costs associated with system failures.

This chart illustrates the various benefits of using pressure reducing relief valves in industrial applications. The percentages indicate the cost savings, reduced downtime, increased efficiency, enhanced safety, and improved equipment lifespan associated with the use of these valves.

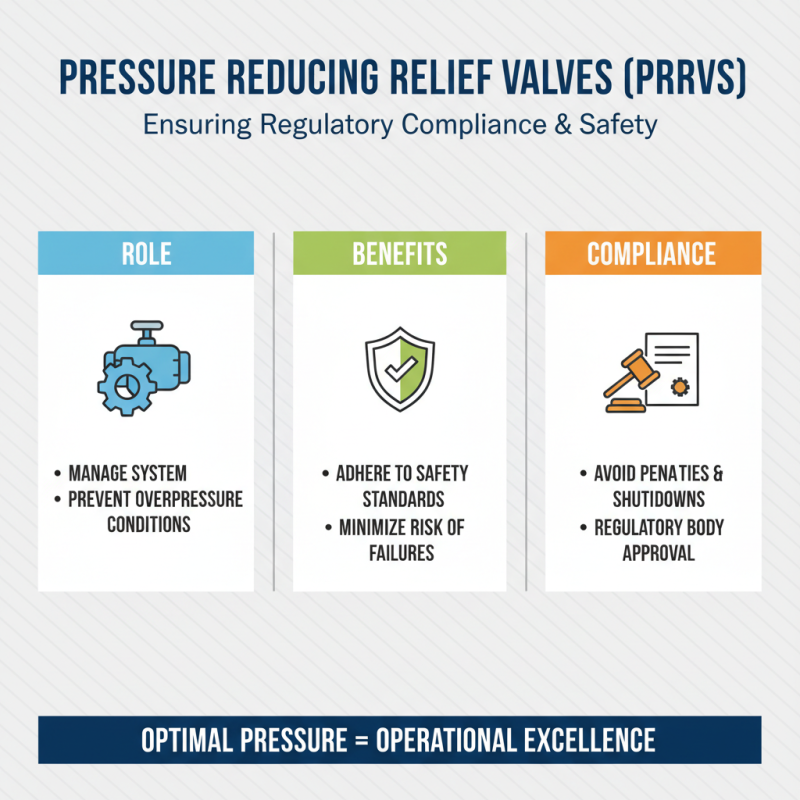

In industrial operations, the use of pressure reducing relief valves (PRRVs) plays a critical role in ensuring regulatory compliance. These valves effectively manage pressure levels within various systems, preventing overpressure conditions that could lead to catastrophic failures or accidents. By maintaining optimal pressure ranges, PRRVs help facilities adhere to safety standards outlined by regulatory bodies, thus minimizing the risk of penalties or shutdowns due to non-compliance.

Furthermore, the implementation of PRRVs contributes to environmental protection regulations by controlling emissions and preventing leaks. With increased scrutiny on industrial operations' environmental impact, companies are increasingly required to demonstrate compliance with legal standards designed to protect the environment. PRRVs not only safeguard the integrity of operational systems but also enable organizations to fulfill legal obligations related to safety and environmental stewardship, ultimately promoting a responsible approach to industrial processes.

In industrial applications, maintaining optimal pressure levels is crucial for the efficiency and reliability of manufacturing systems. Pressure reducing relief valves serve as essential components in achieving enhanced process control and stability. By regulating pressure within a system, these valves help prevent fluctuations that can lead to product inconsistencies or equipment failures. This regulation not only protects sensitive machinery from overpressure but also promotes a steady flow of materials, thereby improving the overall efficiency of production processes.

Furthermore, the implementation of pressure reducing relief valves contributes significantly to system stability. They respond automatically to changes in pressure, ensuring that operations remain within desired parameters. This self-correcting mechanism allows for a smoother operation, reducing the likelihood of unplanned downtime and costly interruptions. With stable pressure conditions, manufacturers can achieve better quality control, leading to increased product reliability and safety in the long run. Overall, the specific advantages offered by these valves are vital in fostering a more controlled and stable environment for various industrial processes.