Leave Your Message

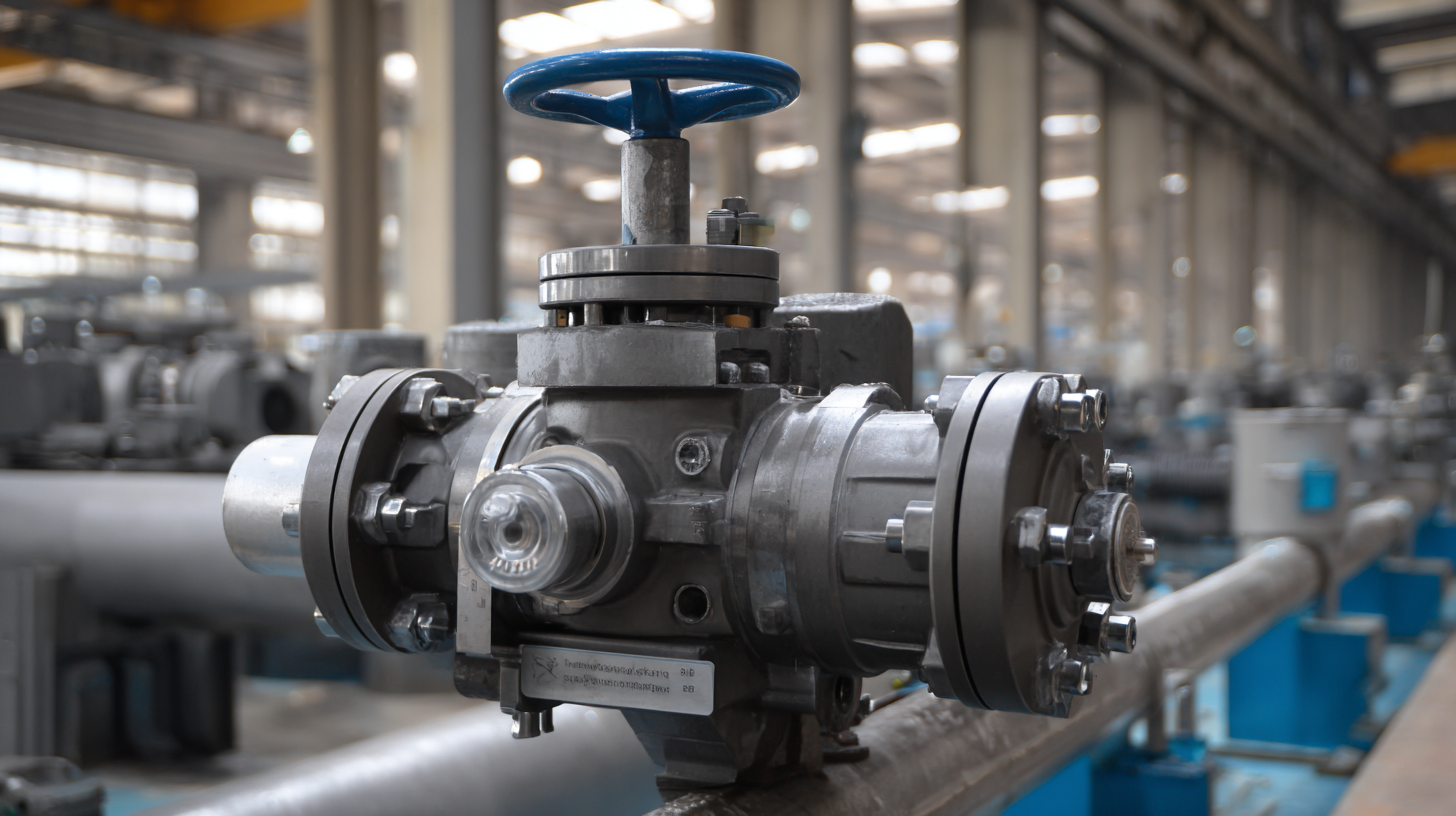

In the realm of industrial applications, the efficiency and reliability of fluid control systems are paramount. Among the various components that contribute to optimal performance, the Pilot Operated Check Valve stands out as a critical element. This innovative valve design not only prevents backflow but also ensures controlled movement of fluids in a system, thereby enhancing operational safety and effectiveness.

The advantages of Pilot Operated Check Valves extend beyond simple functionality; they incorporate automation capabilities that improve responsiveness to system demands, reduce energy consumption, and minimize wear on equipment. As industries strive for improvement in their processes and seek to maintain compliance with stringent regulations, understanding the benefits of integrating Pilot Operated Check Valves becomes essential. This article delves into the unique features and applications of these valves, highlighting why they are a superior choice in modern industrial environments.

The advantages of Pilot Operated Check Valves extend beyond simple functionality; they incorporate automation capabilities that improve responsiveness to system demands, reduce energy consumption, and minimize wear on equipment. As industries strive for improvement in their processes and seek to maintain compliance with stringent regulations, understanding the benefits of integrating Pilot Operated Check Valves becomes essential. This article delves into the unique features and applications of these valves, highlighting why they are a superior choice in modern industrial environments.

Pilot operated check valves (POCVs) offer significant advantages in various industrial applications due to their unique operational mechanisms. One of the core benefits of POCVs is their ability to

prevent backflow while allowing free flow in the intended direction under normal operating conditions. This is especially important in hydraulic systems where

maintaining pressure and flow integrity is crucial for efficient system performance. By utilizing a pilot signal to control the flow, these valves ensure that systems operate

smoothly without the risk of reverse flow, which can lead to equipment damage or operational disruptions.

Another key benefit of pilot operated check valves is their enhanced responsiveness and efficiency in controlling flow rates. The pilot mechanism allows for quicker actuation compared to

conventional check valves, which means that system response times improve significantly. This responsiveness is vital in applications requiring precise fluid control,

such as in manufacturing processes or automated systems. Moreover, POCVs contribute to energy savings, as they reduce the need for additional control devices or systems,

simplifying the overall design and enhancing reliability in industrial settings. The combination of these advantages makes pilot operated check valves a valuable asset

in modern industrial applications.

Pilot operated check valves play a crucial role in various automated systems, enhancing efficiency and safety in industrial applications. One of the key applications is in hydraulic systems, where these valves prevent backflow and maintain pressure during operation. By allowing free flow in one direction while blocking reverse motion, they ensure that actuators and hydraulic cylinders function properly. This capability is essential in environments where precision control of fluid power is necessary, such as in manufacturing and material handling processes.

Another significant application of pilot operated check valves is in mobile equipment like excavators and forklifts. In these systems, they provide reliable control of hydraulic functions, enabling operators to perform tasks with confidence. The valves enhance the responsiveness of the hydraulic machinery by allowing instant release of pressure, which leads to smoother operation and increased productivity. Additionally, the incorporation of these valves contributes to overall system safety by preventing unintended movement, thus protecting both machinery and personnel in dynamic work environments.

This chart illustrates the key advantages of pilot operated check valves in industrial applications, rated out of 10. Notably, pressure maintenance and safety enhancement scored the highest, indicating their critical role in automated systems.

Pilot operated check valves (POCVs) and standard check valves serve crucial roles in regulating fluid flow in industrial systems, but their functionalities and efficiencies differ significantly. A recent industry report by the Fluid Control Association highlights that POCVs can maintain higher operating pressures and lower leakage rates compared to traditional check valves. In applications where precision and reliability are paramount, the ability of POCVs to hold a load while allowing for controlled movement provides a distinct advantage.

Moreover, a comparative analysis conducted by the Valve Manufacturers Association shows that pilot operated check valves can improve system efficiency by up to 25%, particularly in complex hydraulic systems. This enhancement is attributed to their ability to minimize pressure drops and prevent backflow in critical applications. In contrast, standard check valves often struggle under varying pressure conditions, leading to unwanted energy losses and potential system failures. As industries continue to prioritize energy efficiency and system reliability, POCVs are increasingly recognized as a superior option for modern industrial applications.

Pilot Operated Check Valves (POCVs) are essential components in many industrial applications, ensuring fluid flow control and preventing backflow. However, like any mechanical device, they can encounter issues that hinder their performance. Common problems include pilot pressure failure, leakage, and inadequate sealing, which can result in system inefficiencies. According to industry reports, approximately 30% of valve failures are linked to improper installation or maintenance, highlighting the importance of regular checks and servicing protocols.

To troubleshoot these issues effectively, operators should first verify the pilot supply pressure, which must meet the manufacturer's specifications. Additionally, inspecting for any signs of wear or damage on the valve seals and seats can help identify potential leaks. In cases where valves fail to open or close properly, examining the pilot control line for blockages is crucial. A study by the Fluid Power Institute emphasizes that timely maintenance and troubleshooting can extend valve life by up to 40%, leading to significant savings in operational costs while ensuring uninterrupted workflow.

Pilot operated check valves (POCVs) are essential components in many industrial applications, providing reliable flow control while preventing backflow. To maximize their efficiency, implementing best practices is critical. One key aspect is ensuring proper sizing. According to a report by the Hydraulics Institute, valves sized incorrectly can lead to energy losses of up to 30%, impacting overall system performance. Employing flow calculation tools can assist engineers in selecting the right valve size based on application requirements, ensuring optimal operation.

Another best practice involves routine maintenance and testing. A study by the American Society of Mechanical Engineers (ASME) indicates that regular inspection and maintenance can extend valve lifespan by 40%. This involves checking for leaks, ensuring seals are in good condition, and confirming that the pilot control mechanism is functioning correctly. Furthermore, training staff on proper operational techniques enhances reliability and reduces the potential for operational issues, driving efficiency in industrial processes. By implementing these practices, industries can leverage the full advantages of pilot operated check valves, leading to improved reliability and reduced operational costs.