Leave Your Message

In the realm of hydraulic systems, the importance of effective load control cannot be overstated. One of the standout solutions to address this need is the Stacked Counterbalance Valves, which are gaining traction in various industrial applications. According to a recent market research report from Technavio, the global hydraulic valves market is projected to grow at a CAGR of over 4% from 2022 to 2026, reflecting the increasing reliance on sophisticated hydraulic systems in sectors such as construction, agriculture, and manufacturing. These valves offer unique features that enhance machinery safety and efficiency by preventing uncontrolled movement of loads.

This blog will delve into the key benefits and innovative applications of Stacked Counterbalance Valves, showcasing why they are an essential component in modern engineering projects.

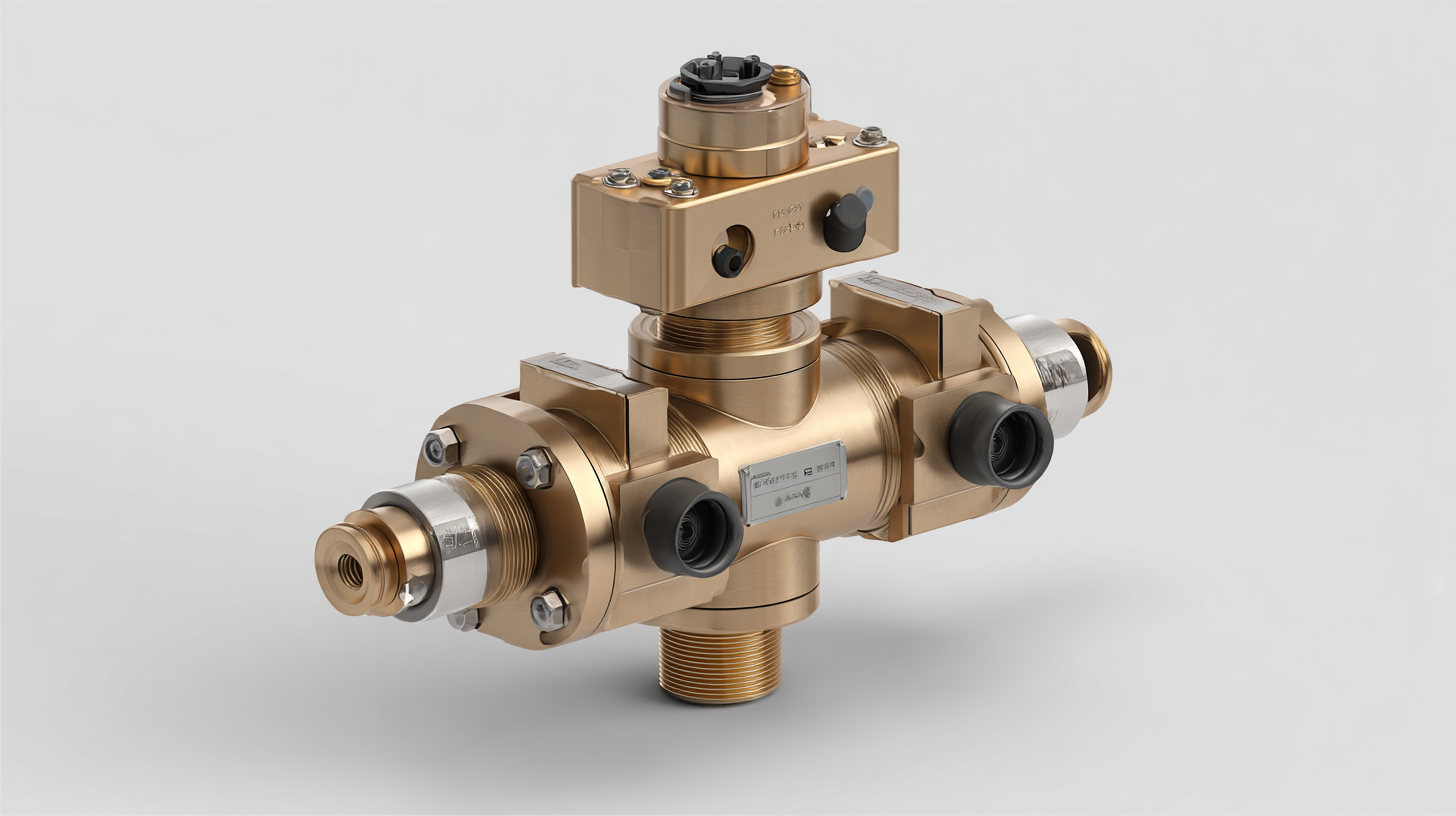

When working on hydraulic systems, understanding the key characteristics of stacked counterbalance valves is essential for optimizing performance while ensuring safety. These valves are designed to control the motion of loads, offering excellent system stability and preventing uncontrolled movements. One notable feature is their integrated design, which allows multiple valves to be stacked together, reducing the overall footprint of the hydraulic system. This not only simplifies installation but also enhances efficiency by minimizing the number of connections and potential leak points.

Another important characteristic is their ability to provide precise control over load dynamics. Top-tier stacked counterbalance valves can maintain a constant pressure differential, ensuring that loads descend smoothly and safely. This precision is crucial in applications where load stability is vital, such as in cranes or material handling equipment. Additionally, many modern designs include adjustable settings, allowing users to fine-tune the valve response to suit specific project needs. Understanding these features can significantly influence the selection of the right valve, enhancing the overall effectiveness of your hydraulic system in diverse applications.

| Valve Model | Max Flow Rate (L/min) | Pressure Rating (bar) | Port Size | Weight (kg) | Key Features |

|---|---|---|---|---|---|

| Model A | 50 | 350 | 1/2" | 1.2 | Compact design, low leakage |

| Model B | 75 | 400 | 3/4" | 1.5 | High response time, adjustable settings |

| Model C | 100 | 500 | 1" | 2.0 | Integrated check valve, high durability |

| Model D | 120 | 600 | 1" | 2.5 | Modular design, easy maintenance |

Stacked counterbalance valves are pivotal components in various industrial applications. They play a crucial role in providing load control and stability in hydraulic systems, making them essential for machinery used in construction, manufacturing, and material handling. By preventing unintended movement of loads, these valves contribute to the safety and efficiency of operations, ensuring that heavy loads can be managed smoothly without risk of tipping or uncontrolled descent.

In industries such as construction, stacked counterbalance valves enable precise control of heavy equipment, allowing operators to perform tasks with increased accuracy. In manufacturing environments, they help maintain consistent pressure and flow, which is vital for automated processes. Furthermore, they are utilized in mobile applications like forklifts and aerial work platforms, where load stability is necessary to ensure the safety of operators and the integrity of materials being handled.

Tips for selecting the right stacked counterbalance valve for your project include assessing the specific load requirements and considering the working environment. It's essential to choose a valve that matches the system's pressure ratings and flow requirements to optimize performance. Additionally, consulting with industry experts can help in understanding the nuances of different valve designs and their suitability for particular applications, ensuring the best fit for your operational needs.

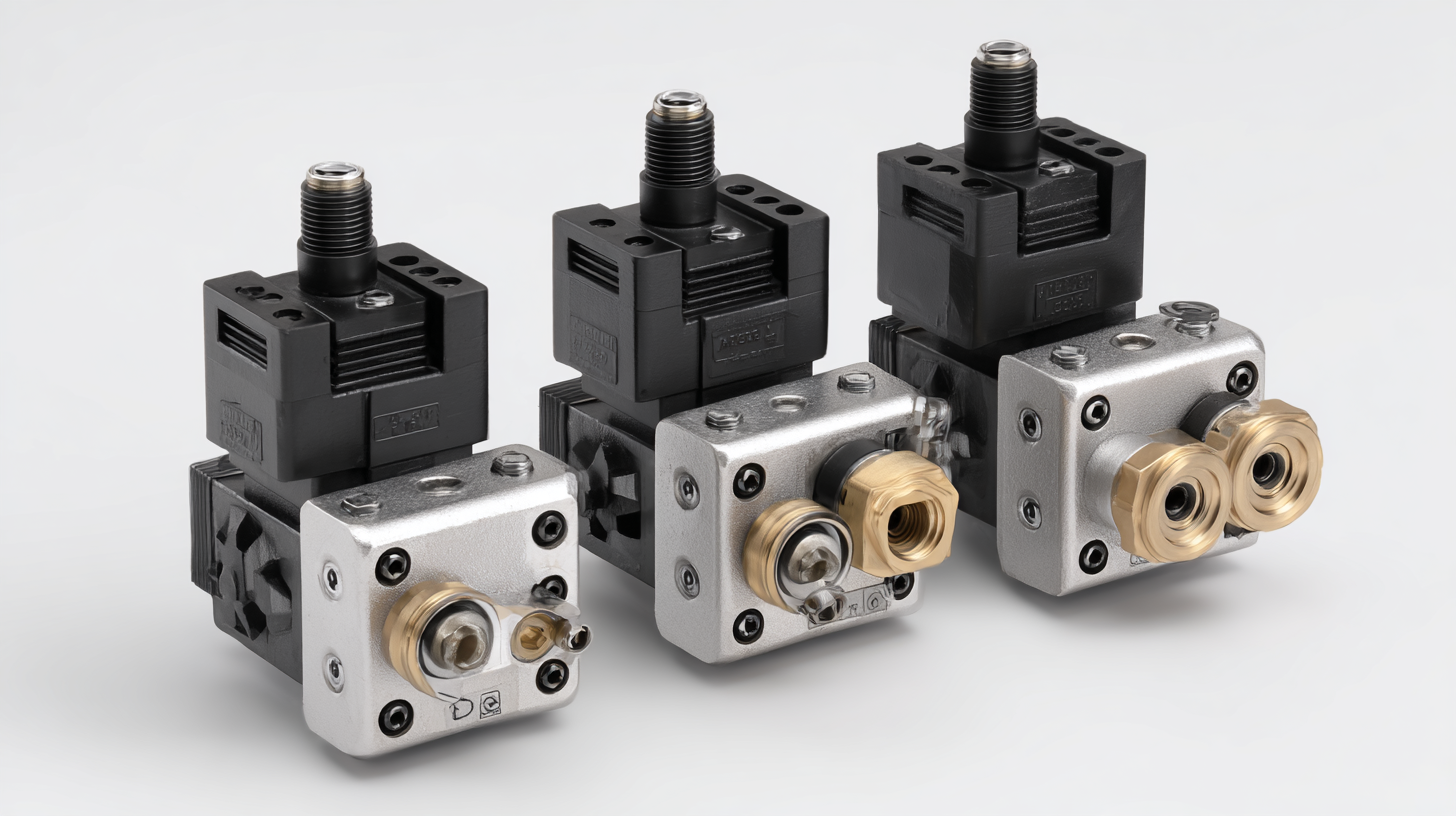

When selecting stacked counterbalance valves for your projects, a comparative analysis of the best models on the market can be invaluable. These valves are designed to control the motion of heavy loads, ensuring safety and stability in hydraulic systems. Key features to consider include their load-holding capability, pressure settings, and response time. Some top-rated models feature adjustable pressure settings, allowing engineers to tailor their performance to specific applications, while others may boast superior thermal stability or corrosion resistance, enhancing their longevity in various environments.

Brands like Parker, Bosch Rexroth, and Eaton offer a range of stacked counterbalance valves, each with unique specifications that cater to different operational needs. For instance, Parker's models are known for their compact design and versatility, making them suitable for tight spaces, while Bosch Rexroth provides enhanced flow rates suitable for high-demand applications. Eaton’s offerings often include integrated electronics for precise control, appealing to automation enthusiasts. Evaluating these features not only aids in selecting the right valve but also contributes to the overall efficiency and safety of hydraulic systems in your projects.

When it comes to installing stacked counterbalance valves, optimal performance hinges on precise installation techniques. These valves play a crucial role in efficiently managing hydraulic pressure in various projects. To begin, ensure that you have a clean and flat mounting surface, as any debris or unevenness can lead to performance issues. Pay special attention to the alignment of the valves with the hydraulic lines, as improper alignment could cause leaks and reduce efficacy.

Another important aspect is the use of appropriate seals and fittings. Selecting the right materials will not only enhance the durability of the installation but also improve overall safety. It's advisable to consult the manufacturer’s guidelines to ensure that the seals you choose are compatible with your specific setup. Additionally, remember to test the installation under controlled conditions after setup, allowing you to identify and rectify any potential issues early on, ensuring a smooth operation of your stacked counterbalance valves in your projects.

Counterbalance valves play a critical role in maintaining stability and efficiency in hydraulic systems. However, they can also be sources of significant operational challenges if not properly managed. Recent incidents highlight issues like pressure buildup in hydraulic power units (HPUs) and the need for frequent adjustments of counterbalance valves on cranes, emphasizing the importance of understanding and troubleshooting these components. When a counterbalance valve isn't calibrated correctly, it can lead to unsafe operating conditions, such as dropped loads or malfunctioning equipment, putting both personnel and projects at risk.

Troubleshooting these valves can be complex but is essential for ensuring optimal performance in various applications. For example, operators may face delays in the opening and closing of hatch doors due to circuit issues, indicating a deeper problem within the hydraulic system. Regular maintenance and precise calibration of counterbalance valves can significantly mitigate these challenges. Keeping a close eye on the performance of these valves and being ready to diagnose issues, such as improper adjustments or leaks, will ensure that machinery operates smoothly and safely, ultimately enhancing project efficiency.