Leave Your Message

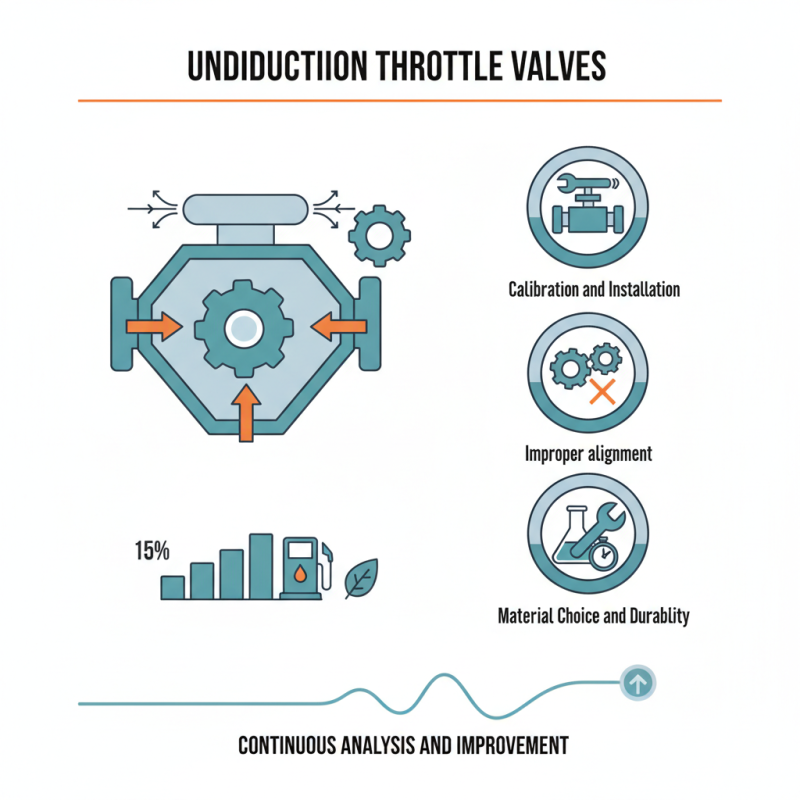

Unidirectional Throttle Valves play a crucial role in optimizing engine performance. According to a recent industry report, these components significantly enhance fuel efficiency in modern automotive applications. In fact, studies indicate that proper throttle valve regulation can lead to a 15% improvement in fuel consumption. Engineers are increasingly recognizing their importance in both performance tuning and emissions control.

However, achieving optimal performance with Unidirectional Throttle Valves requires careful calibration and installation. Many technicians overlook small details, which can lead to subpar engine performance. For instance, improper alignment can restrict airflow, reducing power output and efficiency. Moreover, the choice of materials can affect durability and responsiveness over time. Only by addressing these areas can manufacturers maximize the potential of these throttle systems.

In conclusion, while Unidirectional Throttle Valves offer significant advantages, they are not without challenges. Continuous analysis and improvement are essential. Understanding the intricacies of their function can help automotive professionals achieve the best results.

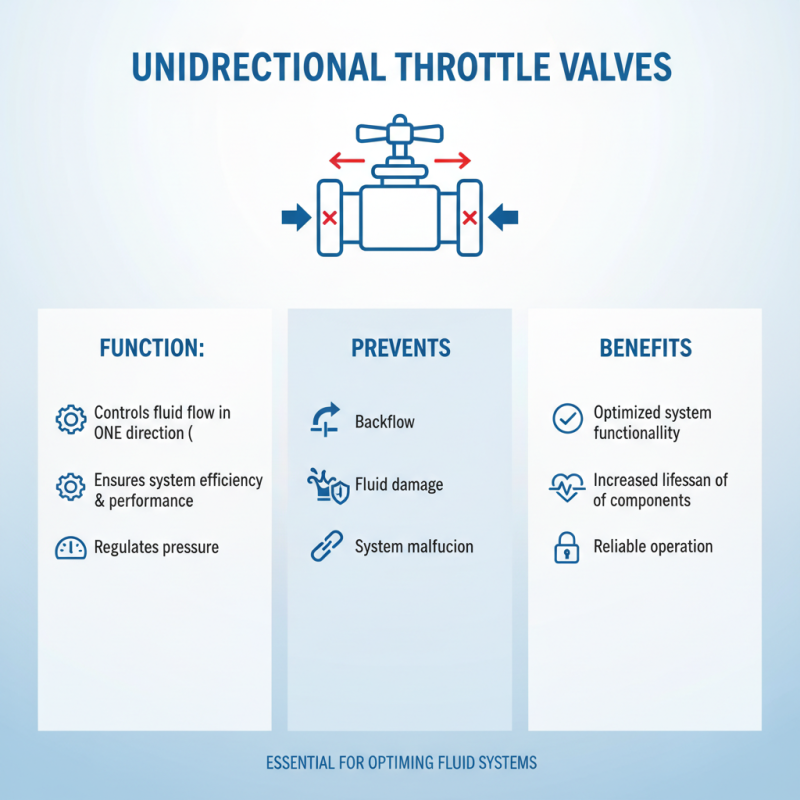

Unidirectional throttle valves are essential in numerous applications. They control the flow of fluids in one direction, ensuring efficiency and performance. Understanding how these valves work is crucial for optimizing system functionality. They regulate pressure and prevent backflow, which can lead to damage over time.

Tips for using unidirectional throttle valves effectively include regular inspections. Check for wear and tear. Any signs of damage can significantly affect performance. Adjust the settings according to your system's needs. Sometimes, the initial settings may not be ideal. Don't hesitate to tweak them for better outcomes.

Another important consideration is the fluid characteristics. Viscosity and temperature can alter valve performance. Make sure to select a valve suitable for your application's specific conditions. Understanding these details can prevent failures and ensure reliability. Prioritize routine maintenance to keep everything running smoothly. It's good to remember that overlooking small issues can lead to larger problems down the line.

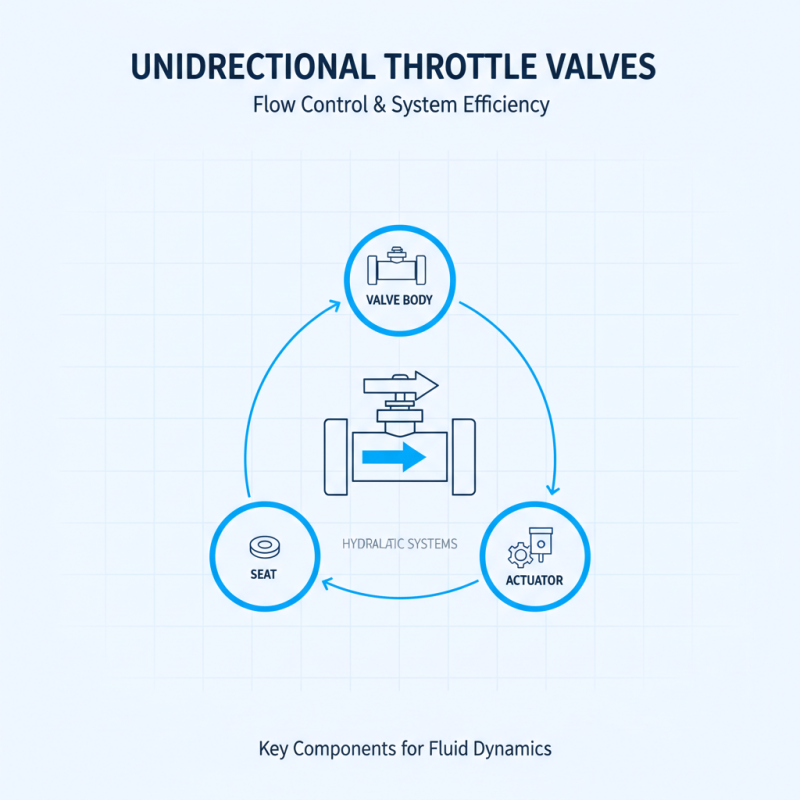

Unidirectional throttle valves are crucial in controlling flow direction and maintaining system efficiency. These valves help manage fluid dynamics in various applications, such as hydraulic systems. Essentially, three key components contribute significantly to their performance: the valve body, the seat, and the actuator.

The valve body serves as the primary structure, determining the design and flow capacity. Materials used, like stainless steel or brass, impact durability. A study found that over 40% of system failures are due to valve body issues. The seat, often made from rubber or polymer, provides a sealing surface. A compromised seat can lead to leaks, resulting in energy loss. It's reported that 30% of maintenance costs in fluid systems originate from faulty seats.

Lastly, the actuator regulates the valve's opening and closing. Its response time is vital for optimal operation. Actuators also influence energy consumption. Efficiency can vary by up to 25% based on actuator choices. Many industries overlook regular testing, leading to performance gaps. Ensuring precision in each component can optimize overall system reliability and effectiveness.

Installing unidirectional throttle valves requires careful attention to detail.

Proper alignment is crucial. Misalignment can lead to inefficiencies. According to a recent industry report,

improper installation can reduce performance by up to 30%.

This highlights the importance of precise positioning.

When attaching the valves, ensure that all connections are tight.

Loose fittings can create leaks, which waste materials and reduce effectiveness. A study indicates that

20% of operational failures stem from leaks at connection points.

Regular checks should be a part of routine maintenance.

Always refer to the manufacturer’s specifications for torque values. Over-tightening can damage components.

It's a balancing act. With proper calibration, users can achieve optimal flow rates. However, many overlook

these specifications, leading to potential system failures. Training and awareness are key. Understanding

these pitfalls will lead to improved performance overall.

Unidirectional throttle valves play a crucial role in engine performance. However, various issues can hinder their effectiveness. Identifying these problems is key to maintaining optimal function.

One common problem is uneven airflow. It can lead to performance inconsistencies. Regularly inspect the valve for debris that may block airflow. Cleaning it can sometimes restore balance. Feel free to check for air leaks as well. Even minor leaks can cause significant performance drops.

Another issue is improper adjustments. A poorly calibrated valve may not respond as expected. Fine-tuning positions can help, but it requires patience. Experimenting with small adjustments helps discover the right balance. Remember, not every configuration is perfect. Documenting performance changes after adjustments can provide valuable insights.

Keep an eye on wear and tear. Over time, components can degrade. This may manifest as sluggish throttle response. Replacing worn parts can restore function. However, consider that some replacements may not fit perfectly. Always test new components thoroughly.

Throttle valves play a crucial role in engine performance. Regular maintenance is key to their efficiency. A recent industry report highlights that up to 30% of throttle valves may operate below optimal performance due to neglect. Dirt and debris can hinder functionality, leading to poor fuel combustion.

Cleaning throttle assemblies can restore function. Use appropriate cleaning agents to avoid damaging components. Inspecting for wear and tear is equally important. Gaskets and seals may degrade over time, causing leaks. Regular checks can help identify potential issues before they escalate. The American Society of Mechanical Engineers suggests checking throttle valves at least once a year.

Lubrication is another key factor. Many overlook this aspect, believing that maintenance is solely about cleaning. In fact, proper lubrication reduces friction and wear, extending the valve’s life. Neglected valves can lead to inefficiency and decreased performance. Consider implementing a routine that includes both cleaning and lubrication. A maintenance plan can help ensure your throttle valves perform at their best.