Leave Your Message

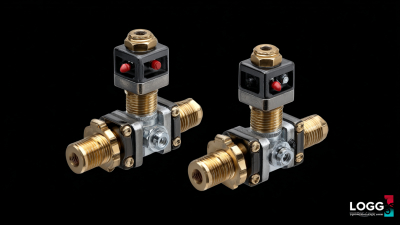

Unidirectional Throttle Valves are pivotal components in fluid control systems, offering distinct advantages that cater to the evolving demands of modern engineering applications.

According to a report by MarketsandMarkets, the global valves market is projected to reach $74.5 billion by 2025, with unidirectional throttle valves playing a significant role due to their efficiency in regulating flow rates and maintaining system stability.

By allowing fluid to flow in one direction while controlling the rate of that flow, these valves enhance performance in critical applications across industries such as oil and gas, water treatment, and automotive engineering.

Their ability to prevent backflow not only safeguards equipment but also improves the overall reliability of intricate systems.

As the push for more sustainable and energy-efficient technologies continues, understanding the key advantages and applications of Unidirectional Throttle Valves becomes increasingly essential for engineers and designers seeking to optimize performance and reliability in their projects.

Unidirectional Throttle Valves are pivotal components in fluid control systems, offering distinct advantages that cater to the evolving demands of modern engineering applications.

According to a report by MarketsandMarkets, the global valves market is projected to reach $74.5 billion by 2025, with unidirectional throttle valves playing a significant role due to their efficiency in regulating flow rates and maintaining system stability.

By allowing fluid to flow in one direction while controlling the rate of that flow, these valves enhance performance in critical applications across industries such as oil and gas, water treatment, and automotive engineering.

Their ability to prevent backflow not only safeguards equipment but also improves the overall reliability of intricate systems.

As the push for more sustainable and energy-efficient technologies continues, understanding the key advantages and applications of Unidirectional Throttle Valves becomes increasingly essential for engineers and designers seeking to optimize performance and reliability in their projects.

Unidirectional throttle valves play a crucial role in fluid control systems, ensuring efficient and stable flow regulation. By allowing fluid to flow in one direction while restricting backflow, these valves enhance system reliability and performance. A report from the International Journal of Fluid Dynamics highlights that implementing unidirectional throttle valves can lead to a 20-30% improvement in energy efficiency in hydraulic systems. This efficiency gain is particularly vital in industries such as manufacturing and automotive, where precise fluid control directly impacts productivity.

Tips: When selecting a unidirectional throttle valve for your system, consider factors such as the fluid type, pressure requirements, and temperature ranges. Proper sizing and material selection can significantly influence the longevity and performance of the valve.

In addition to energy efficiency, unidirectional throttle valves are essential for maintaining optimal pressure levels across various engineering applications. Their ability to manage flow rates allows for better control in processes ranging from chemical manufacturing to water treatment. According to a recent analysis by Market Research Future, the demand for these valves is projected to grow at a CAGR of 6.5% from 2021 to 2028, driven by advancements in fluid control technologies and a focus on automation in industrial applications.

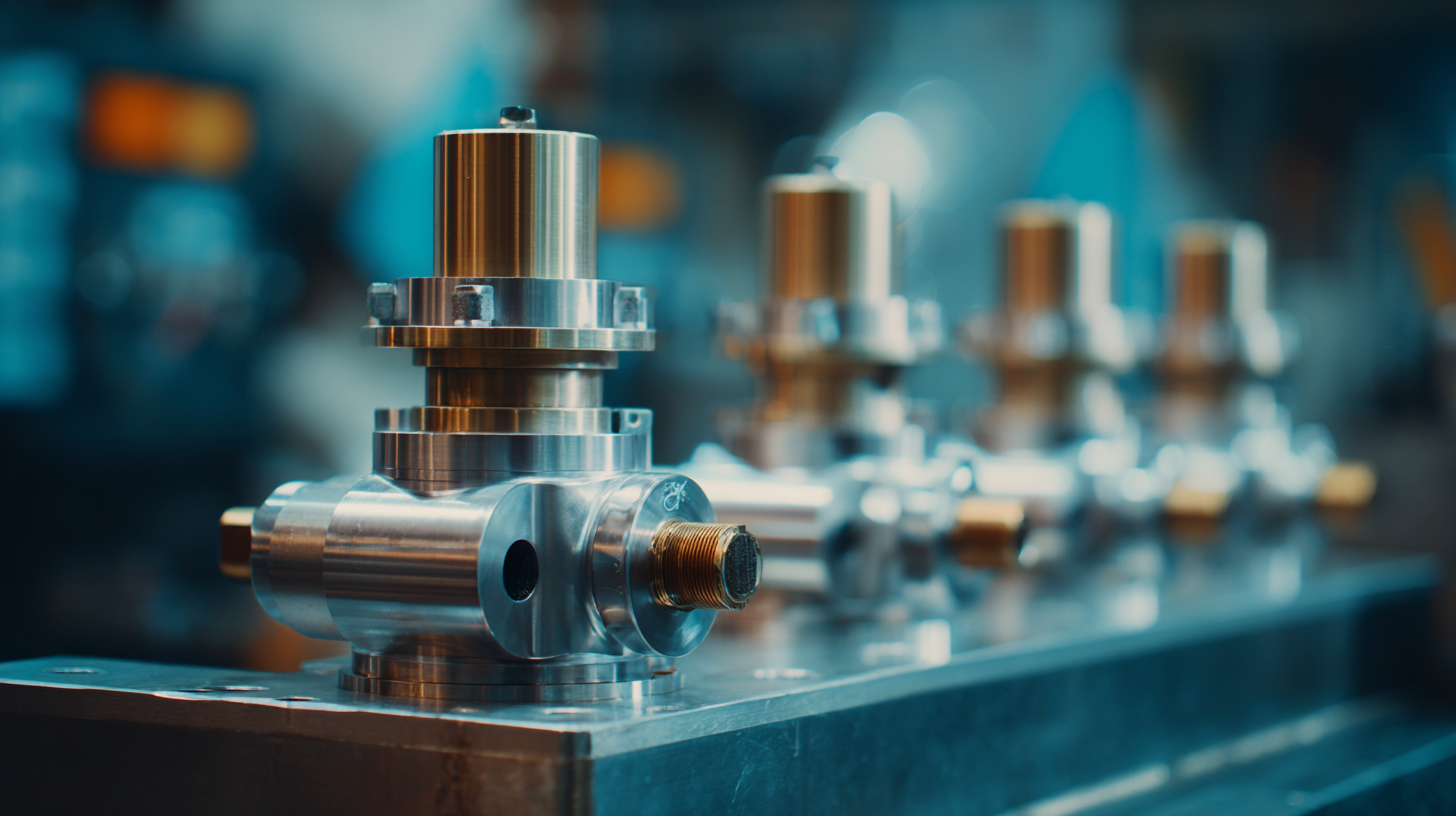

Unidirectional throttle valves have become increasingly vital in modern industrial applications due to their ability to enhance operational efficiency and control. By allowing flow in one direction while preventing backflow, these valves maintain system integrity, reduce energy losses, and minimize wear on equipment. Recent data shows that industries utilizing unidirectional throttle valves experience a significant reduction in pressure drops, leading to energy savings of up to 15% in various applications, making them a cost-effective solution for manufacturers.

Furthermore, the versatility of unidirectional throttle valves makes them suitable for a wide range of industrial environments, including chemical processing, hydraulic systems, and pneumatic applications. According to a report by the International Society of Automation, the adoption of advanced valve technologies, including unidirectional throttle valves, is projected to grow by 8% annually over the next five years. This growth underscores the importance of integrating such components to improve performance and reliability, aligning perfectly with the industry's trend toward automation and efficiency enhancement.

Unidirectional throttle valves play a vital role in enhancing efficiency within modern engineering applications. By regulating fluid flow in a singular direction, these valves prevent backflow and optimize energy consumption. This capability not only increases the system's overall performance but also ensures that machinery operates smoothly, reducing wear and tear on components. As manufacturers strive for more sustainable and efficient systems, the adoption of unidirectional throttle valves is becoming increasingly common in various industries.

Unidirectional throttle valves play a vital role in enhancing efficiency within modern engineering applications. By regulating fluid flow in a singular direction, these valves prevent backflow and optimize energy consumption. This capability not only increases the system's overall performance but also ensures that machinery operates smoothly, reducing wear and tear on components. As manufacturers strive for more sustainable and efficient systems, the adoption of unidirectional throttle valves is becoming increasingly common in various industries.

Tips: To maximize the effectiveness of unidirectional throttle valves in your systems, consider conducting regular maintenance checks. Ensure that they're free from debris and operate without leaks, as even minor disruptions in function can lead to significant inefficiencies. Additionally, selecting the appropriate size and type of valve for your specific application can greatly enhance flow control and operational efficiency.

Incorporating unidirectional throttle valves can result in a notable reduction in energy costs, making them an attractive solution for engineers aiming to innovate in their designs. Their application spans across hydraulic systems, pneumatic tools, and even in water management systems, showcasing their versatility and contribution to modern engineering solutions.

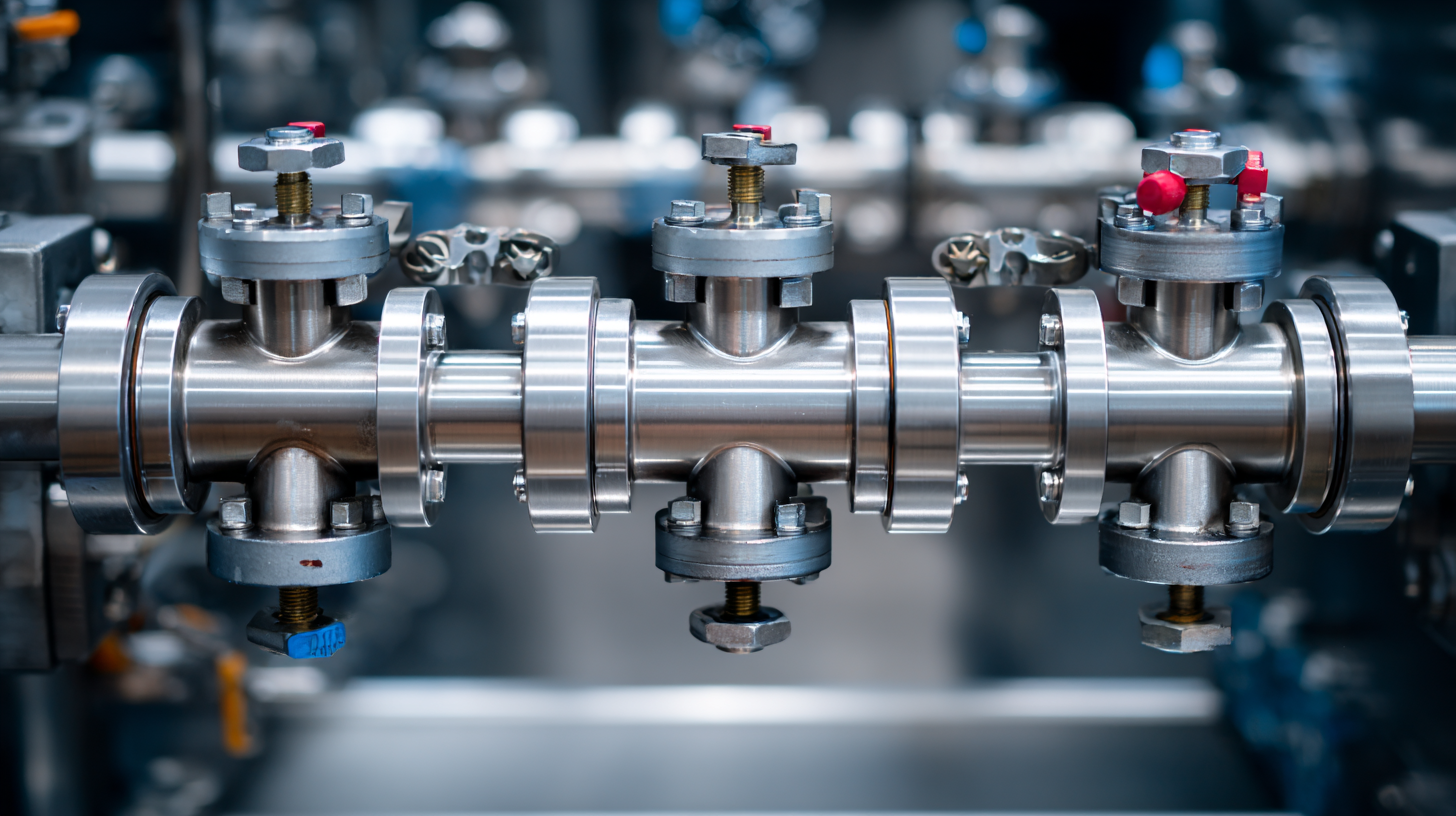

Unidirectional throttle valves play a crucial role in various industrial applications by regulating fluid flow in a controlled manner, ensuring efficiency and safety. In the automotive industry, for instance, these valves are integral to power steering systems, allowing for smoother maneuverability. According to a report by the International Journal of Engine Research, the use of unidirectional throttle valves can enhance vehicle control and responsiveness by improving hydraulic fluid dynamics.

In the realm of manufacturing, unidirectional throttle valves are extensively utilized in pneumatic systems. They ensure that air flows in one direction, preventing backflow and maintaining system integrity. The Global Pneumatic Components Market is projected to reach $7 billion by 2026, with unidirectional throttle valves being a significant contributor due to their reliability and performance in optimizing pneumatic operations. Furthermore, in the chemical processing industry, these valves help maintain precise control over reactive materials, thereby minimizing risks of overpressure and ensuring compliance with safety regulations, as highlighted by the Chemical Engineering Journal, which emphasizes the importance of precision in materials handling.

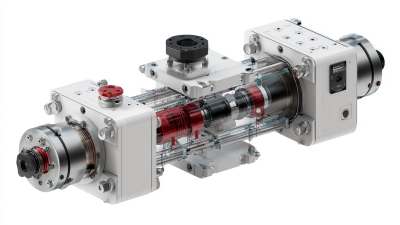

Innovative technologies are rapidly transforming the landscape of unidirectional throttle valves, enhancing their efficiency and integration in modern engineering applications. The advancement of materials, such as high-performance polymers and advanced alloys, allows for improved durability and operational reliability under extreme conditions. According to a recent market research report by Markets and Markets, the global throttle valve market is projected to reach USD 5.3 billion by 2025, growing at a CAGR of 6.8%. This growth is driven by the rising demand for efficient fluid control systems in industries such as automotive, aerospace, and HVAC.

Moreover, the incorporation of smart technologies, such as IoT-enabled sensors and automation, is revolutionizing the functionality of unidirectional throttle valves. These innovations facilitate real-time monitoring and adaptive control, significantly optimizing performance and energy consumption. A study by the International Society of Automation highlights that implementing IoT technologies can improve operational efficiency by over 30%, showcasing the profound impact of these advancements on system performance.

**Tip:** When selecting unidirectional throttle valves, consider opting for those equipped with smart technology for enhanced data-driven decision-making and operational efficiency. Additionally, regularly calculate the lifecycle costs to ensure sustainability in your engineering solutions.

| Feature | Description | Advantages | Applications |

|---|---|---|---|

| Flow Control | Regulates flow in one direction | Prevents backflow, ensuring system efficiency | Hydraulic systems, automotive applications |

| Material Durability | Constructed from robust materials | Long service life, reduced maintenance costs | Industrial machinery, aerospace components |

| Size Variety | Available in multiple sizes | Flexible installation options, tailored solutions | Construction equipment, plumbing systems |

| Pressure Rating | Designed for various pressure conditions | Handles high-pressure environments safely | Oil and gas industries, water treatment facilities |

| Installation Flexibility | Easily integrated into existing systems | Reduces installation downtime | Renewable energy systems, marine applications |