Leave Your Message

Hydraulic lock, a critical phenomenon often overlooked in the realm of fluid mechanics, plays a significant role in various mechanical systems. This occurrence happens when a fluid-filled component, such as an engine cylinder, becomes unable to complete its cycle due to an incompressible fluid's presence, essentially preventing any movement. The understanding of hydraulic lock is crucial for engineers, mechanics, and service personnel alike, as failing to recognize and address this issue can lead to severe mechanical damage and costly repairs.

The causes of hydraulic lock can be multifaceted, including the inadvertent introduction of fluids in areas where they should not be, improper maintenance, or design flaws within the system. The resultant effects can range from diminished performance and efficiency to complete system failures. Therefore, identifying the signs of hydraulic lock early on is vital.

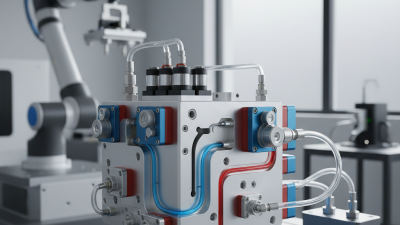

Preventative measures can be implemented to mitigate the risks associated with hydraulic lock. Regular maintenance, diligent inspections, and adherence to operational guidelines can significantly reduce the likelihood of this issue arising. By arming yourself with knowledge about hydraulic lock, you can ensure that your mechanical systems operate smoothly and efficiently, safeguarding your investments and ensuring longevity.

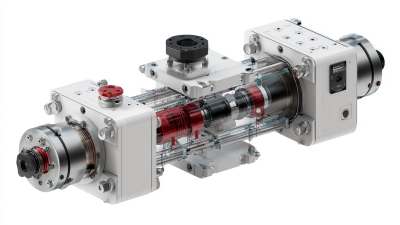

Hydraulic lock, often referred to as hydrolock, occurs when a significant volume of liquid, usually water, enters the combustion chamber of an engine. This situation is problematic because engines are designed to compress air and fuel, not incompressible liquids. The presence of liquid in the cylinders prevents the pistons from moving freely, which can lead to severe mechanical damage.

Hydraulic lock can arise from various scenarios, such as driving through deep water, a failing head gasket, or fuel system leaks. In some cases, poor maintenance might lead to water accumulating in the intake system or the oil system, eventually making its way into the combustion chamber.

Detecting signs of hydraulic lock can be tricky, but symptoms often include unusual noises from the engine, difficulty turning the starter, or a sudden loss of power while driving. Preventative measures, such as regular inspections and ensuring that air intake systems are secure and free of obstruction, can significantly reduce the risk of encountering this alarming issue.

Hydraulic lock, often referred to as hydrolock, is a serious condition that can occur in engines when liquid enters the combustion chamber. One of the most common causes of hydraulic lock is water ingestion. This can happen during heavy rainfall or if a vehicle drives through deep water. When excess water enters the cylinder, it occupies space meant for the air-fuel mixture, leading to a failure in normal compression and causing potential catastrophic damage to the engine.

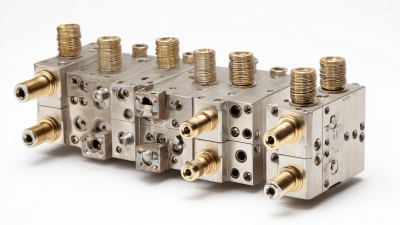

Another significant cause of hydraulic lock is coolant leaks from the cooling system. If a gasket fails or a seal becomes compromised, coolant can seep into the engine's cylinders. This is particularly dangerous as the coolant not only prevents proper combustion but can also lead to rust and corrosion over time, further exacerbating engine issues. Additionally, incorrect fueling—such as introducing gasoline into a diesel engine—can similarly result in a hydraulic lock scenario, highlighting the importance of proper fuel management. Understanding these common causes can help in implementing preventative measures to avoid this costly engine malfunction.

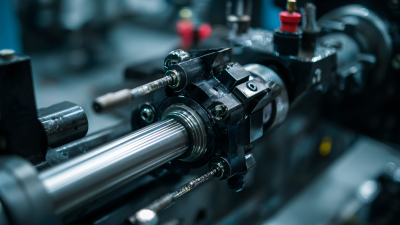

Hydraulic lock occurs when an engine cylinder fills with liquid, preventing the piston from completing its stroke. This condition can severely compromise engine performance and functionality. When hydraulic lock is present, the force generated during the compression stroke meets resistance from the incompressible fluid, leading to a sudden and potentially catastrophic failure. Components such as connecting rods may bend or break, and the crankshaft could sustain damage, all of which can lead to extensive and costly repairs.

The effects of hydraulic lock extend beyond immediate mechanical failure. An engine experiencing this condition can show signs of loss of power, inefficient fuel combustion, and increased emissions. When an engine is unable to operate as designed, it can lead to a cascade of performance issues, including rough idling, stalling, and failure to start.

Preventative measures, such as ensuring that fluid levels are appropriate and conducting regular maintenance checks, are crucial for maintaining engine health and avoiding the damaging consequences of hydraulic lock. By understanding these effects and potential risks, vehicle owners can take proactive steps to protect their engines.

Hydraulic lock is a condition that can occur in vehicles when a liquid, typically oil or fuel, enters the engine cylinder and prevents the piston from completing its stroke. This can lead to severe engine damage if not addressed promptly. To avoid such a catastrophic failure, implementing prevention strategies is crucial.

One key strategy is to maintain proper fluid levels and ensure the integrity of the fuel and oil systems. Regularly checking for leaks or signs of liquid accumulation in the engine components can help catch issues before they escalate. Additionally, it’s important to use the correct fluid specifications for your vehicle to prevent any compatibility issues that may lead to hydraulic lock.

**Tips:** Always consult your vehicle's manual for recommended maintenance schedules and fluid types. If you notice any unexpected performance changes, such as difficulty starting or unusual engine noises, have your vehicle inspected immediately. Keeping your vehicle in a well-ventilated area can also help reduce moisture buildup, further minimizing the risk of hydraulic lock. By taking these preventive measures, you can significantly decrease the chances of encountering hydraulic lock and ensure your vehicle operates smoothly.

Diagnosing hydraulic lock issues in engines requires a methodical approach to pinpoint the underlying cause. Typically, hydraulic lock occurs when an engine cylinder fills with an incompressible fluid, usually due to water or fuel entering the combustion chamber. Mechanics often begin with a visual inspection, checking for signs of fluid in the oil or evidence of coolant leaks. Tools like compression gauges can be employed to assess cylinder pressure; significantly reduced or zero readings across affected cylinders may indicate hydraulic lock presence.

Once diagnosed, repairing hydraulic lock can involve several steps, depending on the severity of the issue. If water is the culprit, removing the spark plugs and cranking the engine can help expel the fluid. In more severe cases, disassembling the engine may be required to clean the cylinders properly and check for underlying damage. It’s also essential to address the root cause, whether it’s a failing head gasket, intake leak, or another form of fluid ingress, to prevent future occurrences. Regular maintenance and timely inspections can help catch potential issues early, reducing the risk of experiencing hydraulic lock.

| Dimension | Details |

|---|---|

| Causes of Hydraulic Lock | Excessive fluid in the cylinder, Faulty head gasket, Internal engine damage |

| Common Effects | Engine misfires, Overheating, Potential engine failure |

| Prevention Tips | Regular oil checks, Timely replacements of worn gaskets, Routine engine inspections |

| Diagnosis Methods | Visual inspection, Pressure tests, Engine performance monitoring |

| Repair Techniques | Drain excess fluid, Replace gaskets, Rebuild or replace damaged components |