Leave Your Message

In the ever-evolving landscape of hydraulic systems, sourcing the best Stacked Hydraulic Manifolds has become increasingly critical for engineers and project managers alike. Recent industry reports indicate that the global hydraulic manifold market is projected to reach USD 4.1 billion by 2026, growing at a CAGR of 5.2%. This surge is driven by the rising demand for efficient and compact hydraulic solutions across various sectors, including agriculture, construction, and manufacturing.

As hydraulic systems strive for enhanced performance and reliability, the choice of manifold design plays a pivotal role in optimizing flow, minimizing leaks, and improving system responsiveness. In this ultimate guide, we will explore essential sourcing strategies and best practices to help you make informed decisions when selecting Stacked Hydraulic Manifolds that meet the specific needs of your projects.

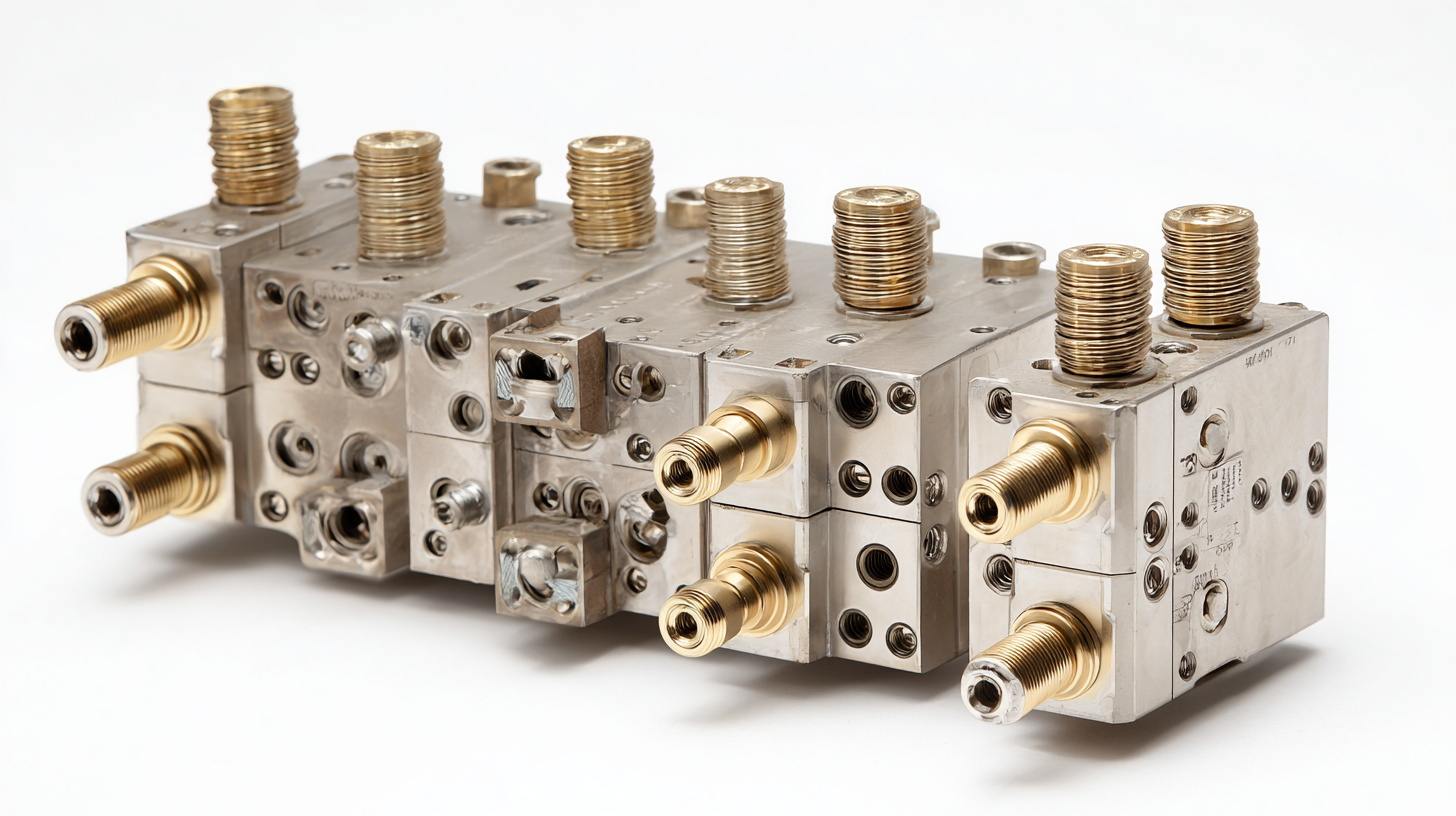

Stacked hydraulic manifolds have emerged as a pivotal component in modern hydraulic systems, providing optimal efficiency and performance. These manifolds consolidate multiple hydraulic functions into a single unit, streamlining installation and reducing the risk of leaks by minimizing connections. According to a report by the International Electro-Technical Commission, systems utilizing stacked manifolds can see up to a 30% reduction in assembly time and a significant drop in pressure drops across the system.

One of the key features of stacked hydraulic manifolds is their customizable design, which allows engineers to tailor the configuration according to specific project needs. This flexibility can improve system efficiency by up to 25%, as reported by the Hydraulic Institute. Furthermore, these manifolds can be integrated with advanced sensors and control systems, which enhance monitoring capabilities and improve overall reliability.

**Tip:** When selecting a stacked hydraulic manifold, consider the flow rate and pressure specifications of your application to ensure optimal performance. Another tip is to prioritize manufacturers that offer detailed technical support, as this can aid in maximizing the manifold's efficiency and addressing any engineering challenges during installation.

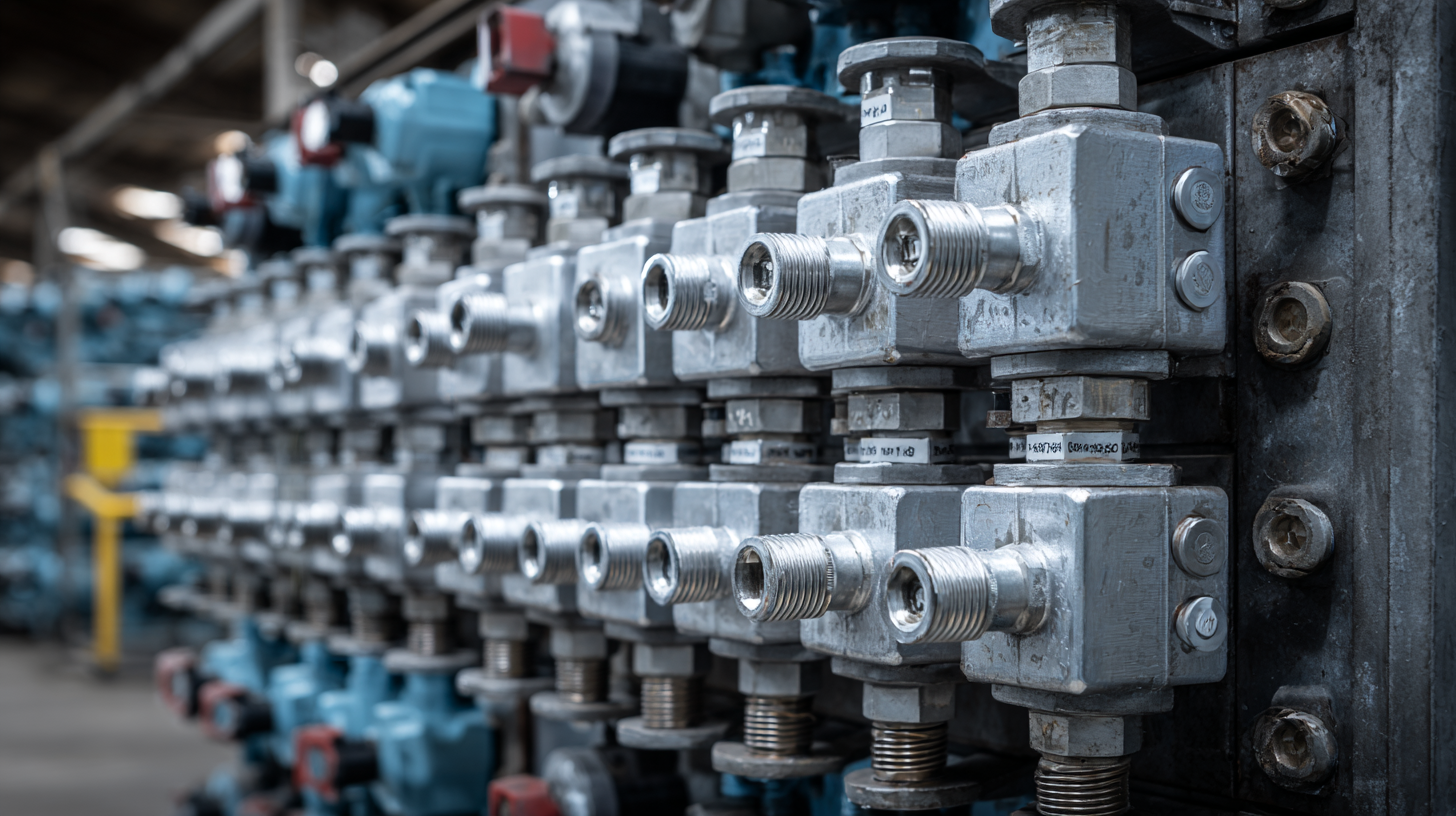

When it comes to sourcing stacked hydraulic manifolds, evaluating your options is paramount to ensure you select the right manufacturer for your project. Begin by assessing the quality of products offered by different manufacturers. Look for companies that adhere to industry standards and possess certifications that guarantee reliability and performance. Requesting samples or case studies can further provide insights into the durability and functionality of their manifolds. Speak to previous clients or analyze online reviews to ascertain their reputation in delivering high-quality components consistently.

Cost is also a significant factor to consider. While it's tempting to opt for the cheapest option available, a lower price may often correlate with inferior quality, which could lead to issues in operation and potential additional costs in the long run. Compare pricing structures of several manufacturers and ensure that you’re examining similar specifications. Negotiate with suppliers to find value-driven solutions that balance both cost and quality, keeping in mind that investing in superior components may enhance overall project success and reduce maintenance expenses.

When sourcing stacked hydraulic manifolds for your projects, understanding industry standards and regulations is paramount to ensuring optimal performance and safety. Various international and national standards, such as ISO 4414 and ANSI B93.170, outline the specifications for hydraulic systems, including manifold design and testing procedures. Adhering to these regulations not only enhances the reliability of the hydraulic system but also promotes safety for operators and the environment. Ignoring these standards could lead to system failures, which can have costly repercussions.

Furthermore, manufacturers often undergo rigorous certification processes to validate their compliance with industry standards. Selecting a supplier with recognized certifications—such as CE marking or ISO certification—can significantly reduce risks associated with non-compliance. It's essential to perform due diligence by requesting documentation and verifying the manufacturing processes against industry benchmarks. By prioritizing compliance in your sourcing decisions, you can ensure your hydraulic manifolds meet the necessary operational safety and performance criteria, ultimately leading to successful project outcomes.

In recent years, stacked hydraulic manifolds have emerged as a game-changer in the fluid power industry, significantly enhancing the efficiency and compactness of hydraulic systems. In a case study involving the automotive sector, the implementation of stacked hydraulic manifolds led to a 20% reduction in the overall size of hydraulic installations while simultaneously improving flow rates and response times. This not only streamlined production processes but also reduced energy consumption, aligning with the industry's shift towards sustainability.

One notable example is the use of stacked hydraulic manifolds in construction machinery. A leading manufacturer reported that integrating these systems enabled a 30% increase in operational efficiency, allowing for smoother functions and minimized downtime. This was particularly evident in excavators, where improved hydraulic responses can be directly linked to enhanced productivity on job sites.

Tip: When sourcing stacked hydraulic manifolds, prioritize suppliers who provide customizable solutions tailored to your project needs. This can make a significant difference in achieving optimal performance.

Tip: Always consider the compatibility of manifolds with existing systems. Conducting thorough analysis and testing can prevent costly modifications later on.

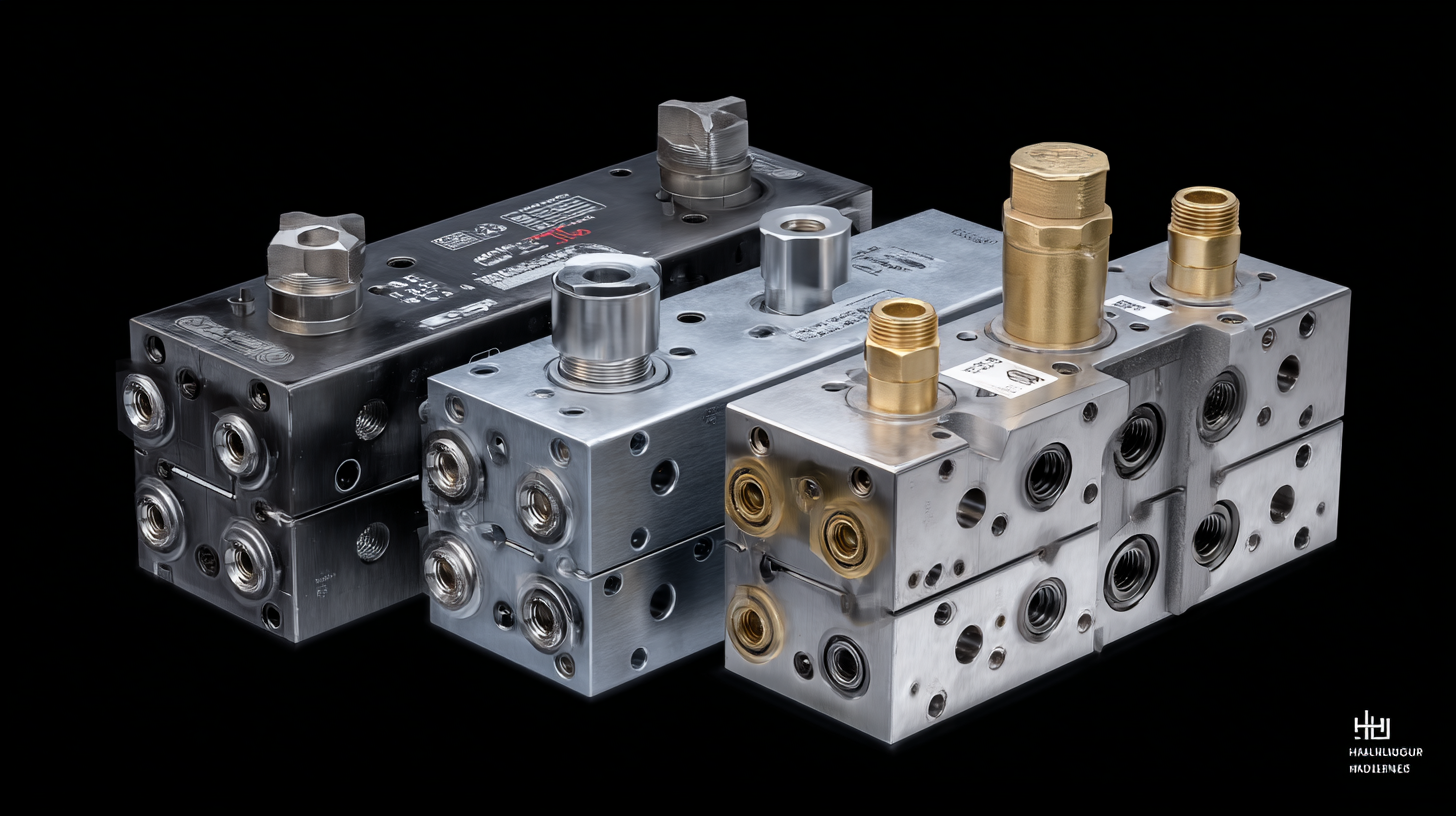

The world of stacked hydraulic manifolds is undergoing a significant transformation, driven by innovations in design and technology that are becoming increasingly vital for diverse industrial applications. One of the most promising trends is the integration of smart technologies into manifold systems. By incorporating IoT sensors, manufacturers can monitor performance and detect inefficiencies in real time, ensuring optimal functioning and reducing downtime. This proactive approach to maintenance not only enhances operational reliability but also lowers overall costs.

Another key advancement in manifold design is the move towards more compact and lightweight configurations. As industries strive for increased efficiency and sustainability, the demand for space-saving solutions is on the rise. Modern stacked hydraulic manifolds are being engineered with advanced materials, such as composites and lightweight alloys, that offer high strength-to-weight ratios. This innovation not only minimizes installation space but also improves energy efficiency, allowing hydraulic systems to operate at lower pressures and consume less energy. As these trends evolve, they promise to reshape the landscape of hydraulic systems, paving the way for enhanced performance and sustainability in future engineering projects.

| Feature | Description | Innovation Grade | Application Area | Sustainability Factor |

|---|---|---|---|---|

| Compact Design | Reduction in space requirements for installation, allowing for more versatile system designs. | High | Manufacturing, Aerospace | Good |

| Integrated Sensors | Real-time monitoring of pressure, flow rates, and temperature for enhanced control. | Very High | Robotics, Automotive | Excellent |

| Modular Construction | Easier to customize and upgrade systems without replacing entire units. | Medium | Construction, Agriculture | Good |

| Advanced Materials | Use of lightweight and durable materials enhance performance and longevity. | High | Heavy Equipment, Marine | Very Good |

| Smart Connectivity | Integration with IoT for data-driven insights and predictive maintenance. | Very High | Mining, Energy | Excellent |