Leave Your Message

In the modern industrial landscape, the efficiency and reliability of machinery operations are paramount. A key component in achieving this efficiency is the Hydraulic Lift Valve Manifold, which serves as the nerve center for hydraulic systems. According to industry reports, the global hydraulic manifold market is projected to grow significantly, with a compound annual growth rate (CAGR) of 4.5% from 2021 to 2028. This growth underscores the critical role hydraulic systems play in diverse sectors such as construction, manufacturing, and renewable energy.

The choice of Hydraulic Lift Valve Manifold directly impacts machinery performance, energy consumption, and operational safety. A well-designed manifold system not only facilitates superior fluid control but also optimizes space within hydraulic assemblies, resulting in enhanced overall system efficiency. As organizations strive to decrease downtime and maximize output, investing in high-quality hydraulic manifolds has become essential. By 2025, it is anticipated that the advancements in hydraulic technology will further enhance the functionality and versatility of Hydraulic Lift Valve Manifolds, making them indispensable for future machinery operations in various industries.

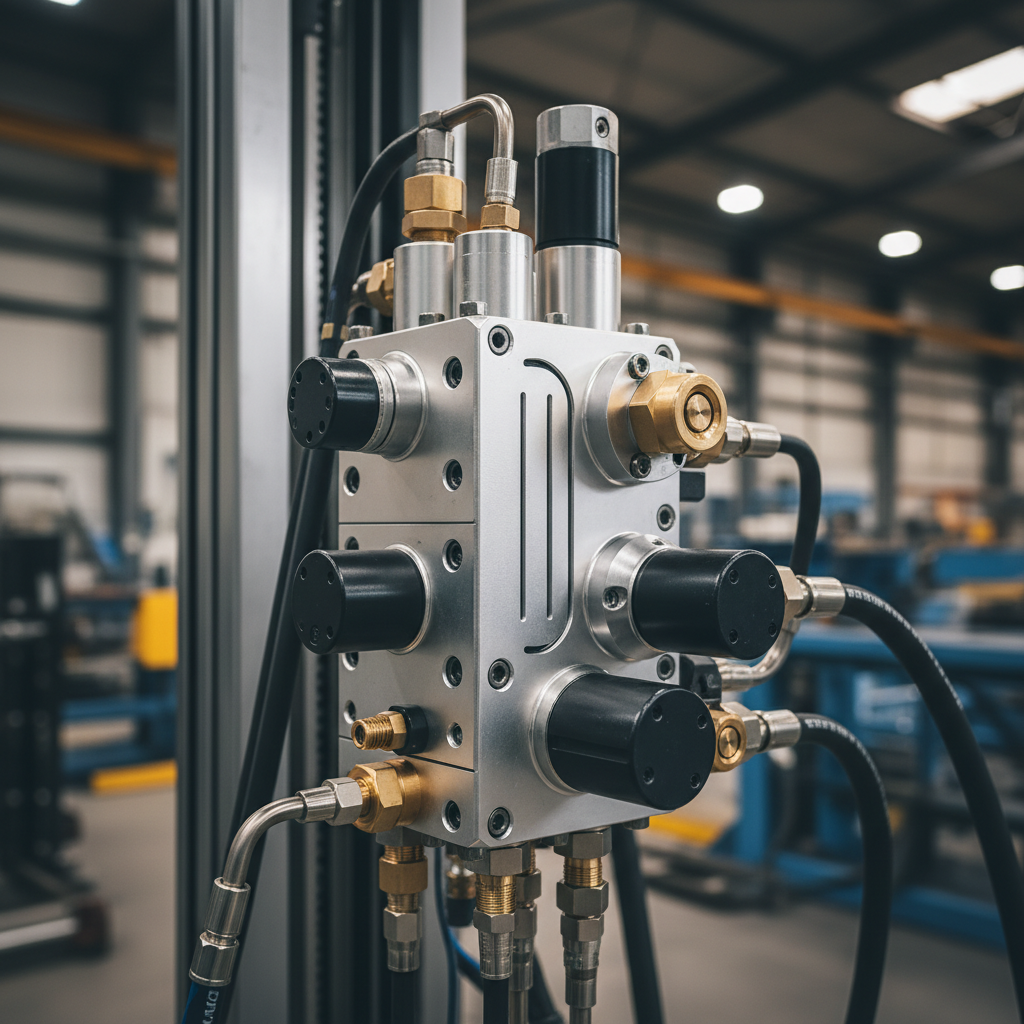

When selecting hydraulic lift valve manifolds, several key features are essential for ensuring efficient operation and durability. First and foremost, the material construction plays a crucial role in performance. According to a report by MarketResearchFuture, manifolds made from high-strength steel or aluminum are preferred due to their ability to withstand high pressures while minimizing weight, which can significantly enhance machinery efficiency.

Another critical aspect to consider is the configuration of the manifold. A well-designed manifold allows for streamlined fluid flow, reducing pressure drops and potential system losses. The International Journal of Fluid Power emphasizes that optimizing fluid dynamics can lead to a 15% increase in overall system efficiency. Additionally, compatibility with various hydraulic components is vital. Ensuring that the manifold accommodates different valve types and sizes can greatly enhance system flexibility and allow for easier maintenance and upgrades.

Finally, the choice of seals and fittings cannot be overlooked. High-quality seals prevent leaks and ensure longevity, while appropriate fittings can enhance serviceability. The Hydraulic Institute reports that using premium couplings can reduce maintenance costs by up to 30%, underscoring the importance of incorporating high-quality components in your manifold selection.

The advancements in hydraulic lift valve technology are critical for enhancing machinery performance across various industries. As the hydraulics market is projected to reach $44.26 billion by 2030, the focus on efficient operation is paramount. Recent trends indicate a significant shift towards integrating variable valve timing (VVT) systems, which optimize engine performance by adjusting the timing of valve openings and closings based on operational conditions. This not only improves efficiency but also reduces emissions, aligning with global sustainability goals.

Furthermore, the mobile hydraulics sector is anticipated to grow steadily, reaching USD 34.37 billion by 2033. This growth is driven by innovations in hydraulic components such as pumps, cylinders, and valves. Recent reports emphasize the importance of enhanced designs in components like valvesprings. Improved valvespring technology has revolutionized installation processes, boosting reliability and performance in high-stakes applications. As industries continue to evolve, the incorporation of advanced hydraulic technologies will play a pivotal role in driving operational efficiency and achieving competitive advantages.

In today's competitive landscape, the efficiency of machinery operations heavily relies on the performance of hydraulic lift valve manifolds. These critical components play a vital role in managing fluid flow and pressure in hydraulic systems, ensuring that machinery operates smoothly and reliably. A comparative analysis of the top hydraulic lift valve manifolds on the market reveals that several brands have distinguished themselves through innovative designs and advanced features, catering to the growing demand for enhanced hydraulic solutions.

As the global hydraulics market is projected to grow significantly, reaching an estimated worth of $44.26 billion by 2030, manufacturers are increasingly focused on developing high-performance valve manifolds. Key considerations include the manifolds' capacity to withstand extreme pressure and their compatibility with various hydraulic fluids. By evaluating their specifications, efficiency ratings, and user feedback, industry professionals can make informed decisions tailored to their operational needs. This increasing attention to hydraulic lift valve manifolds signifies a broader trend within the market, as organizations seek to optimize their machinery's performance while reducing downtime and maintenance costs.

Proper maintenance of hydraulic lift valve systems is crucial for ensuring their longevity and optimal performance. Regular inspections should be conducted to identify any signs of wear or damage. Check for leaks, corrosion, or debris in the valves and surrounding areas, as these issues can lead to decreased efficiency and potential system failures. Keeping the hydraulic fluid at the correct level and quality is also vital. Contaminated or degraded fluid can cause premature wear on the internal components, so it’s essential to change the fluid as recommended by the manufacturer.

In addition to fluid maintenance, lubricating the moving parts of the hydraulic lift valve is necessary to minimize friction and prevent premature wearing. Utilize high-quality lubricants and ensure that all grease fittings are properly serviced. Another important aspect is to monitor the operating temperature of the system; excessive heat can cause damage to seals and other components. Implementing a proper cooling system can help maintain ideal operating conditions. By adhering to these maintenance tips, you can extend the life of your hydraulic lift valve systems and ensure smooth and efficient machinery operation over time.

This chart presents the flow rate performance of the top five hydraulic lift valve manifolds. Ensuring optimal flow rates is crucial for effective machinery operation and maintenance. Regularly monitoring these parameters can help enhance the longevity of hydraulic systems.

Upgrading to modern hydraulic lift valve manifolds can significantly enhance the efficiency of machinery operations. The cost-benefit analysis reveals that while the initial investment may seem substantial, the long-term savings and performance improvements often outweigh these costs. Modern manifolds are designed with better materials and technology, offering increased durability and reliability. This translates into reduced maintenance costs and fewer downtime incidents, which are crucial for maintaining productivity.

Moreover, the integration of advanced features such as built-in diagnostic tools can streamline the troubleshooting process. Quick identification of issues minimizes operational interruptions, further contributing to cost savings. Facilities can also benefit from improved energy efficiency, as modern manifolds optimize hydraulic fluid flow, reducing overall energy consumption. Thus, the transition to these upgraded systems fosters not only enhanced functionality but also delivers a strong return on investment over time, making it a wise decision for any operation reliant on hydraulic machinery.

| Model | Flow Rate (L/min) | Max Pressure (bar) | Material | Cost ($) | Durability Rating (Years) |

|---|---|---|---|---|---|

| Model A | 120 | 250 | Aluminum | 450 | 10 |

| Model B | 150 | 300 | Steel | 600 | 12 |

| Model C | 130 | 270 | Composite | 550 | 9 |

| Model D | 110 | 230 | Aluminum | 400 | 8 |

| Model E | 100 | 220 | Steel | 350 | 7 |