Leave Your Message

Pressure Control Valves play a critical role in various industries. They ensure safe and efficient operations in systems dealing with liquids and gases. According to a recent market report, the demand for these valves is expected to grow by 5% annually. This highlights their importance in modern engineering.

In sectors like oil and gas, improper pressure control can lead to catastrophic failures. Statistics reveal that equipment failures cost the industry billions each year. Pressure Control Valves help mitigate such risks by maintaining optimal pressure levels. However, not all valves perform equally.

Choosing the right valve requires careful consideration. Factors like material, maximum pressure, and temperature ratings must be assessed. Many users overlook these details, leading to performance issues. Awareness of top products on the market can significantly enhance safety and efficiency in any operation.

Pressure control valves play a crucial role in various industries. They maintain the desired pressure in piping systems by regulating fluid flow. This regulation helps protect equipment and ensures operational efficiency. Without these valves, systems can easily become over-pressurized, leading to failures or dangerous situations.

Tips: Regular maintenance is essential. Check for leaks and ensure proper functioning. Always keep spare parts on hand for quick replacements.

In many cases, operators overlook the importance of proper sizing. An incorrectly sized valve can cause significant issues. It may lead to either excessive pressure drops or inefficient flow rates. Understanding the specific needs of your system is vital for optimal performance.

Tips: Review system specifications carefully. Consult with experts or reliable resources when making selections. Always consider environmental factors that could affect valve performance.

When selecting pressure control valves, key features matter significantly. One essential aspect is the valve's pressure range. An ideal valve should be capable of handling both high and low-pressure extremes. A report by the American Society of Mechanical Engineers indicates that valves with a wide pressure range increase system reliability by up to 30%.

Another critical feature is the response time of the valve. A rapid response can be essential in preventing system failures. According to industry studies, valves that respond within two seconds can minimize pressure spikes, ensuring smoother operations. It's vital to consult technical specifications before making a choice.

**Tip:** Always evaluate your system's specific needs. Understanding the flow characteristics can guide you to the right choice. Choose valves that minimize noise and vibration as they perform better in dynamic systems.

Additionally, consider materials and construction. Corrosion-resistant materials enhance durability and reduce maintenance costs. A mismatch can lead to costly downtimes. While it's easy to overlook, understanding the environment where the valve will be installed is crucial for longevity.

**Tip:** Test your selected valve under real-world conditions before committing. This can unveil potential issues that might not be obvious in a catalog.

| Valve Model | Type | Pressure Range | Material | Features |

|---|---|---|---|---|

| Model A | Spring-loaded | 0-150 psi | Stainless Steel | Corrosion-resistant, Adjustable |

| Model B | Pneumatic | 0-200 psi | Brass | Low noise, High sensitivity |

| Model C | Electro-hydraulic | 0-300 psi | Aluminum | Remote control, Fast response |

| Model D | Diaphragm | 0-100 psi | PVC | Lightweight, Non-toxic |

| Model E | Pilot-operated | 0-500 psi | Carbon Steel | High flow, Durable |

| Model F | Electric | 0-400 psi | Stainless Steel | Automatic control, Energy efficient |

| Model G | Check Valve | 0-600 psi | Bronze | Prevents backflow, Compact design |

| Model H | Two-stage | 0-350 psi | Alloy Steel | Stability over wide range, High precision |

| Model I | Spring-return | 0-250 psi | Nylon Composite | Lightweight, Resistant to chemicals |

| Model J | Modulating | 0-700 psi | Titanium | High precision control, Resistant to corrosion |

When selecting pressure control valves, understanding their specifications is crucial. These valves manage fluid pressure effectively in various systems. They come in several types, such as relief valves, reducing valves, and back pressure valves. Each type serves a unique purpose. A relief valve opens at a preset pressure to prevent system overload. Conversely, a reducing valve ensures downstream pressure remains constant, regardless of fluctuations upstream.

For deeper insight, consider the materials used in these valves. Common materials include stainless steel and brass, chosen for durability. The size of valves plays a critical role too. Proper sizing prevents cavitation and ensures efficiency. However, users often overlook this aspect. Improper sizing can lead to significant failures and costly repairs.

Another detail is the pressure range of each valve. It's essential to match the valve's specifications to your system requirements. Some valves operate well in lower pressures but fail at higher ones. This mismatch often leads to inefficiencies. Attention to detail is vital in selecting the right valve for optimal performance and safety. Always conduct thorough research before making a choice.

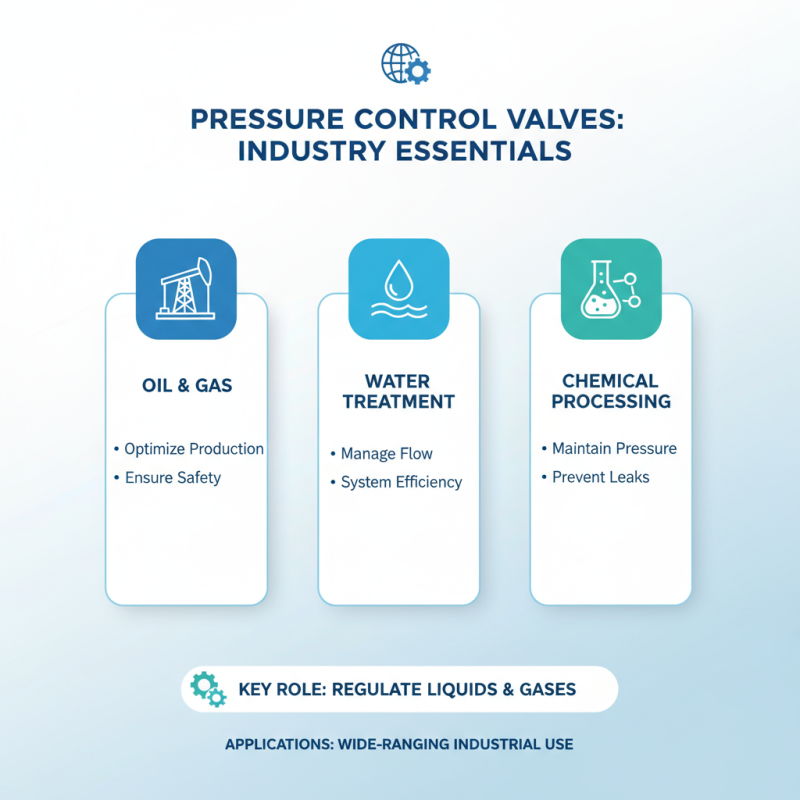

Pressure control valves play a crucial role across various industries. They help maintain the appropriate pressure in systems that involve liquids and gases. Common applications include oil and gas, water treatment, and chemical processing. In oil and gas, these valves optimize production rates and ensure safety. In water treatment, they help manage flow and keep systems efficient.

Tips: Regular maintenance is key. Inspect valves for leaks often. This can help avoid costly downtime.

In chemical processing, pressure control valves ensure that reactions occur under safe conditions. They regulate pressure fluctuations that could compromise product quality. In addition, industries like pharmaceuticals use these valves to maintain sterile environments. Clean processes lead to better outcomes.

Tips: Choose the right valve type for your application. Compatibility matters. It can prevent issues down the line.

Fields like food processing also benefit from these valves. They ensure proper pressure during food production, impacting safety and taste. Overall, pressure control valves are vital for operational efficiency across sectors.

Pressure control valves are essential in various industries. Proper maintenance ensures they function optimally for years. Understanding how to care for these valves is crucial.

Regular inspection is the first step. Check for leaks and corrosion. These issues can escalate quickly. Clean the valve surface to prevent buildup. Use soft cloths and mild cleaners. Harsh chemicals may cause damage.

Periodic testing of the valve’s response can reveal underlying problems. If you notice erratic pressure fluctuations, it could indicate wear. Consider replacing seals and gaskets if needed. This maintenance task can save you from costly repairs later.

Finally, keep an eye on the operational environment. High temperatures or exposure to contaminants can affect valve performance. Protective covers might help. Adapting your maintenance routine based on the valve’s location is wise.