Leave Your Message

When it comes to optimizing the performance of your hydraulic system, selecting the right Pipe Counterbalance Valves is critical. These valves play a significant role in controlling the speed and stability of hydraulic actuators, ensuring safe and efficient operation. However, with a myriad of options available on the market, choosing the best Pipe Counterbalance Valves can be a daunting task. This guide aims to simplify the selection process by outlining essential tips and considerations that will help you make an informed decision. By understanding the key factors such as load requirements, application specifics, and compatibility with your existing system, you can enhance the reliability and efficiency of your hydraulic applications. Discover how to navigate through these complexities and select the ideal Pipe Counterbalance Valves tailored to your unique needs.

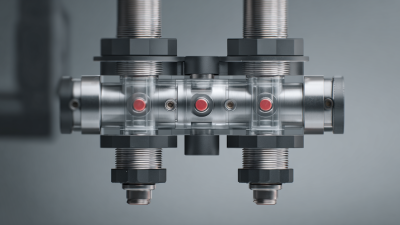

When selecting pipe counterbalance valves for a hydraulic system, understanding their key specifications and adherence to industry standards is crucial. These valves are designed to prevent uncontrolled movements in hydraulic cylinders, making them essential for applications requiring precise control of load and motion. Key specifications to consider include the valve's pressure rating, flow capacity, and leakage rates. It’s essential to choose a valve that can withstand the maximum operating pressure of your system while providing adequate flow to maintain performance efficiency.

Moreover, familiarity with industry standards governing counterbalance valves can guide your selection process. Standards from organizations such as the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI) help ensure safety and reliability. Compliance with these standards not only guarantees a certain level of quality but also facilitates compatibility with other system components. Evaluating the certifications and performance metrics of potential valves will help you make an informed decision, ensuring that the chosen valve meets both your technical requirements and industry regulations.

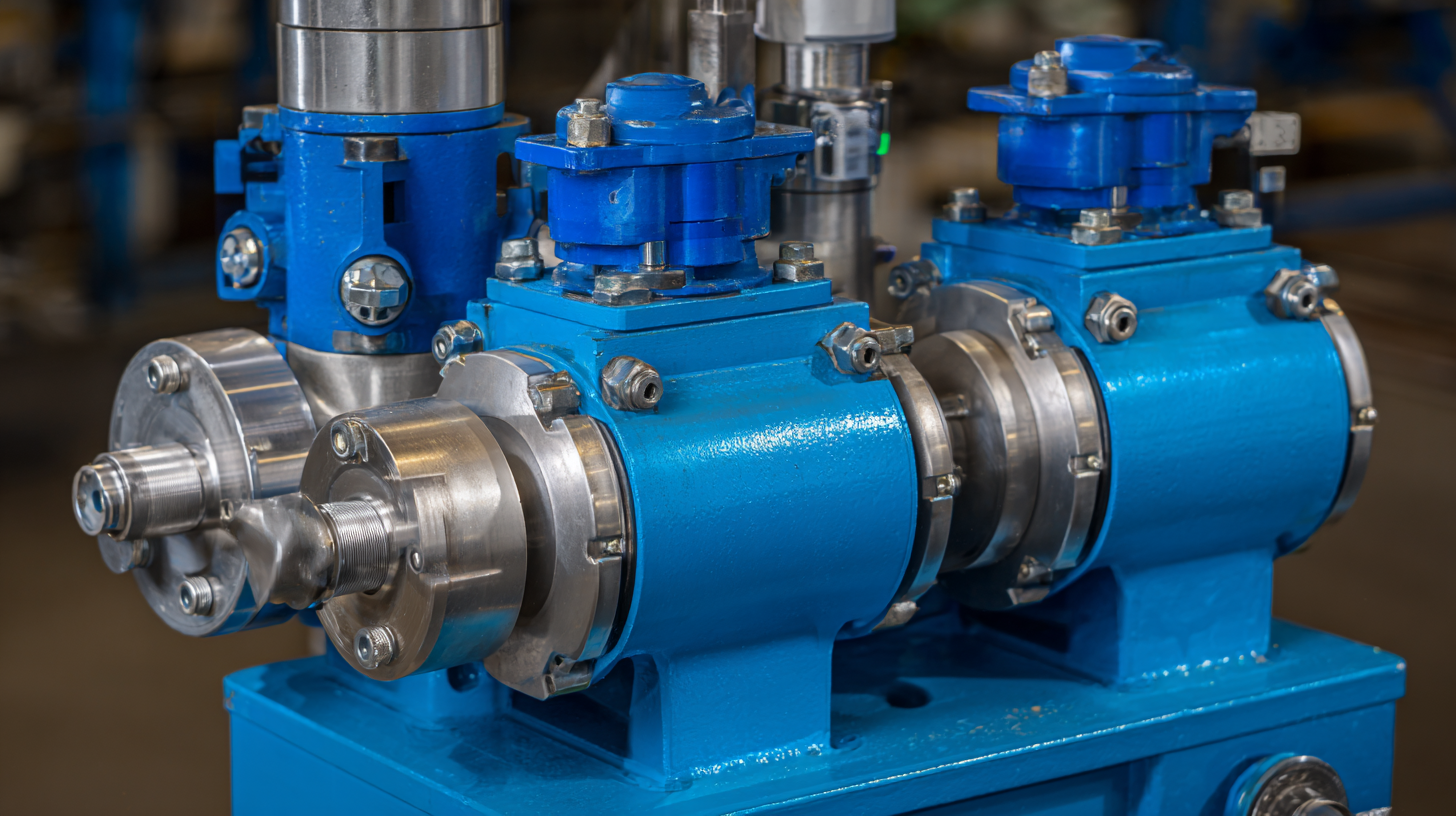

When selecting pipe counterbalance valves for your hydraulic system, understanding how valve size impacts hydraulic efficiency is essential. The size of the valve determines the flow rate and pressure within the system, which directly influences the performance of hydraulic applications. A larger valve can typically handle greater volumes of fluid, making it suitable for high-demand operations. Conversely, smaller valves may be more efficient in systems with lower flow requirements, allowing for better control and response times.

Tips: When assessing valve size, consider the specifics of your hydraulic system, including the maximum flow rate and system pressure. It's crucial to match valve sizes appropriately to avoid inefficiencies or potential system failures. Additionally, ensure that the material of the valve aligns with the fluids being handled, as this can also affect performance and durability.

Moreover, the advancements in technology have led to a variety of valve types, such as manual and electric axial flow valves, making it easier to find the right fit for different applications. For instance, in sectors like water treatment and oil and gas, precision in flow control can enhance operational efficiency and reduce costs. Remember to analyze your specific application requirements thoroughly to choose the most effective valve size that optimizes hydraulic efficiency.

When selecting the best pipe counterbalance valves for your hydraulic system, evaluating pressure ratings is crucial for ensuring optimal performance. According to industry reports, the structural design of a valve significantly impacts its pressure-holding capability. For instance, a recent study on pressure-maintaining ball valve structures highlights that optimization can improve their performance in high-pressure applications, potentially increasing the operational reliability of hydraulic systems.

Understanding the pressure dynamics within your hydraulic system is essential. The state-of-the-art techniques for assessing valve performance include numerical simulations and analytical evaluations that provide insights into how design variables affect pressure ratings. For example, the implementation of advanced modeling techniques in valve design processes can lead to substantial improvements in both efficiency and safety. Studies indicate that valves with enhanced structural integrity can withstand greater pressure fluctuations, making them ideal for dynamic hydraulic systems. Therefore, investing time in analyzing and selecting counterbalance valves based on precise pressure ratings will lead to better performance and longer service life in your hydraulic applications.

| Valve Type | Pressure Rating (psi) | Flow Rate (GPM) | Temperature Range (°F) | Material |

|---|---|---|---|---|

| Directional Control Valve | 3000 | 25 | -40 to 220 | Aluminum |

| Pressure Relief Valve | 3500 | 20 | -20 to 180 | Steel |

| Counterbalance Valve | 4000 | 15 | -30 to 210 | Cast Iron |

| Flow Control Valve | 2500 | 30 | -40 to 200 | Brass |

When selecting pipe counterbalance valves for hydraulic systems, it’s essential to understand the various types available and their specific industrial applications. One common type is the pilot-operated counterbalance valve, which is suitable for controlling heavy loads by maintaining a pre-set pressure. This design is ideal for applications in construction machinery, where stability and load control are paramount. The valve reacts to changes in load, ensuring that the machinery operates safely and efficiently under varying conditions.

Another type is the direct-operated counterbalance valve, known for its simplicity and quick response time. These valves are often used in mobile equipment and material handling applications, as they can efficiently manage the descent of loads without relying on complex feedback systems. Understanding the requirements of your hydraulic system, such as load dynamics and response time, is crucial in choosing the right counterbalance valve. By considering these factors, industries can optimize performance and ensure the reliability of their hydraulic systems.

Proper maintenance of hydraulic counterbalance valves is essential for ensuring their longevity and optimal performance. Regular inspections are crucial for identifying any signs of wear, leaks, or corrosion. It's advisable to implement a routine check-up schedule, allowing operators to promptly address issues before they escalate. Maintaining clean hydraulic fluid is also important, as contaminated fluid can lead to valve malfunction and reduced efficiency. Using filtration systems and regularly changing the hydraulic fluid will help prolong the life of the counterbalance valves.

Proper maintenance of hydraulic counterbalance valves is essential for ensuring their longevity and optimal performance. Regular inspections are crucial for identifying any signs of wear, leaks, or corrosion. It's advisable to implement a routine check-up schedule, allowing operators to promptly address issues before they escalate. Maintaining clean hydraulic fluid is also important, as contaminated fluid can lead to valve malfunction and reduced efficiency. Using filtration systems and regularly changing the hydraulic fluid will help prolong the life of the counterbalance valves.

Another critical aspect of maintenance is to ensure that the valve settings are correctly adjusted to the specifications of the hydraulic system. Misadjustments can lead to improper function, potentially causing safety hazards during operation. Operators should be trained to understand the operating parameters and how to make necessary adjustments safely. Additionally, keeping the surrounding environment clean and free from debris can help minimize external factors that may affect the valves’ functionality. By following these best practices, users can enhance the performance and durability of their hydraulic counterbalance valves.