Leave Your Message

In the realm of hydraulic systems, Pipe Counterbalance Valves play a crucial role. These valves help control the movement of fluids in pipes. They ensure that the load stays in place during operation, which is vital for safety and efficiency. When hydraulic systems engage, unintentional movement can lead to accidents or equipment damage.

Understanding how Pipe Counterbalance Valves function can illuminate their significance. These valves maintain pressure in one direction while allowing free flow in another. This balance is essential for controlling heavy loads effectively. However, improper installation or maintenance can hinder their performance.

Overall, while Pipe Counterbalance Valves are often overlooked, they are key components in many applications. Their proper function supports stability and precision in various operations. It is worth reflecting on the potential issues that may arise without them. Recognizing their importance can lead to safer hydraulic practices.

A pipe counterbalance valve is a crucial hydraulic component. Its main purpose is to control load and prevent unexpected movements in hydraulic systems. This is especially important in applications like cranes and excavators. According to the National Fluid Power Association, up to 20% of hydraulic failures relate to load control issues. Therefore, having reliable counterbalance valves can enhance safety and efficiency.

The function of the valve is simple yet effective. When the load is stationary, the valve maintains hydraulic pressure. This stops the load from falling unexpectedly. When the operator actuates the system, the valve opens to allow fluid flow. A study by the Fluid Power Society shows that using counterbalance valves can improve system stability by 30%. This data highlights the importance of integrating these valves into hydraulic designs.

However, selecting the right valve can be tricky. Many factors need to be considered, like load types and system pressure. Some engineers overlook these aspects, which could lead to system failures. Regular maintenance is also often neglected, resulting in poor performance. Awareness of these challenges can lead to better engineering practices in the hydraulic field.

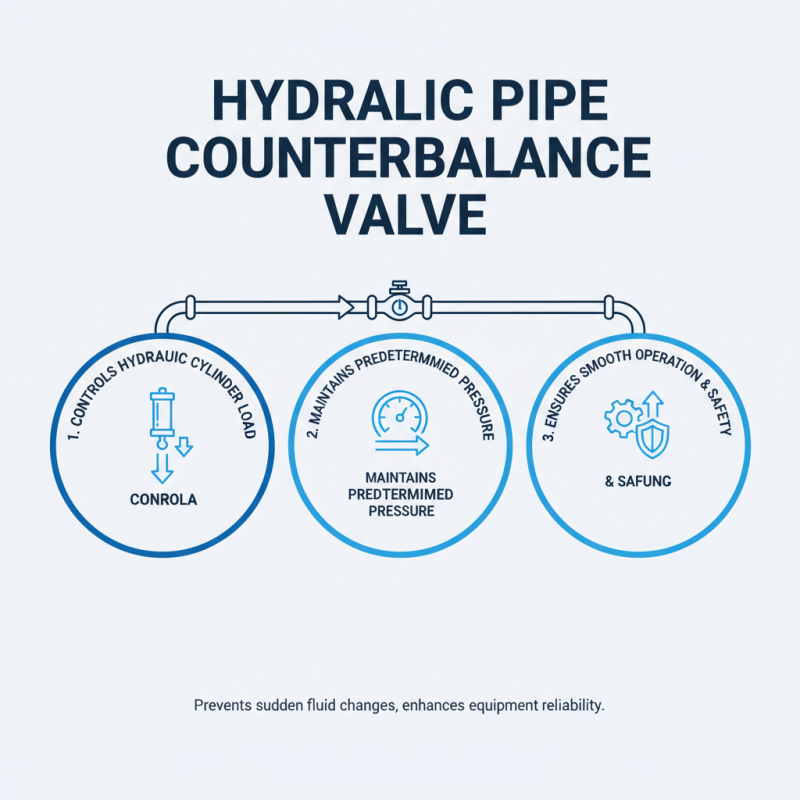

A pipe counterbalance valve plays a critical role in hydraulic systems. Its primary function is to control the load on hydraulic cylinders. By maintaining a predetermined pressure, these valves prevent sudden changes in fluid flow. This ensures smooth operation and enhances safety in equipment.

According to industry reports, the global demand for hydraulic components is expected to grow by 5% annually. As more industries adopt hydraulic systems, the relevance of counterbalance valves increases. These valves help manage the force exerted by heavy loads, thereby minimizing risks. A poorly calibrated valve can lead to equipment failure. This could result in costly downtime and dangerous situations.

In practice, a pipe counterbalance valve regulates the pressure in hydraulic circuits. When a load moves down, the valve opens, allowing fluid to escape. If the load rises, the valve closes to maintain pressure. This dynamic balancing creates stability. However, if the valve malfunctions, it can compromise the entire system. Regular maintenance is vital, yet often overlooked. It's crucial to reflect on how these components impact overall system efficiency and safety.

Pipe counterbalance valves are essential components in hydraulic systems. They control the flow of hydraulic fluid in equipment like cranes and forklifts. These valves prevent sudden drops in load, ensuring safety and stability. A study by Industry Research reveals that over 30% of machinery accidents are linked to improper load management. Hence, understanding the components of counterbalance valves is crucial.

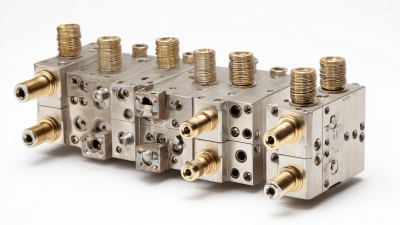

Key components include the valve body, adjusting screw, and pilot. The valve body regulates the fluid flow. The adjusting screw allows for precise control over the counterbalance pressure. The pilot ensures that the load does not fall unexpectedly. Each element plays a vital role in system efficiency. However, if not properly calibrated, these components can lead to reduced performance. In fact, improper settings can increase the risk of hydraulic failure by 25%, according to recent data from the Fluid Power Society.

Regular maintenance of these valves is necessary but often overlooked. Operators may neglect routine checks, leading to equipment malfunctions. This negligence can result in costly downtime. Moreover, inadequate training on valve operation can worsen the situation. Understanding each component's importance can help prevent mishaps and improve overall system reliability.

Pipe counterbalance valves play a crucial role in various industrial settings. They are primarily used in hydraulic systems to control load motion. These valves help to maintain the stability of heavy equipment during operations. This is especially important in construction and material handling. Without them, equipment could experience uncontrolled movement.

You can find these valves in excavators, cranes, and forklifts. In excavators, they prevent the arm from dropping too quickly. This ensures operator safety and reduces material spillage. In cranes, they help manage loads when lifting and lowering. They make operations smoother and more predictable.

While these valves are effective, they can be misunderstood. Some users fail to calibrate them properly. Others overlook their maintenance. Such mistakes can lead to system failures, which are costly. Regular checks and adjustments are essential for optimal performance. Educating operators about these valves is key to enhancing their efficiency.

| Dimension | Description | Application Area | Working Principle |

|---|---|---|---|

| Flow Rate | The maximum fluid flow the valve can handle. | Construction and Machinery | Controls the speed of actuator movements. |

| Pressure Rating | The maximum pressure the valve can withstand. | Material Handling Equipment | Maintains load stability in various positions. |

| Size | The physical dimensions of the valve. | Agricultural Equipment | Prevents uncontrolled descent of loads. |

| Temperature Range | The ambient temperature range in which the valve operates efficiently. | Automotive Industry | Regulates pressure changes caused by temperature variations. |

| Control Type | Manual or automatic control mechanisms. | Elevating Systems | Ensures controlled movement of lifting equipment. |

When evaluating counterbalance valves, performance metrics are crucial. Key metrics include response time, flow capacity, and load-holding ability. According to industry reports, valves that respond within 10 milliseconds exhibit optimal performance in dynamic applications. This response time is essential for machinery operating under varying loads.

Many operators overlook load-holding ability, often assuming all valves perform similarly. However, data indicates that some models can hold loads up to 20% better than others. This difference can significantly impact overall system efficiency and safety. A thorough evaluation using this critical metric shows that selecting the right valve is not only beneficial but necessary.

Tips: Always check the valve's specifications before selection. Understanding the maximum load limits can prevent potential failures. Additionally, regular maintenance can enhance the valve's performance. Ignoring maintenance might lead to reduced efficiency or even catastrophic failure. Adapting performance metrics to your specific application allows for better decision-making and improved operational safety.

This chart illustrates the performance metrics of pipe counterbalance valves, showcasing their efficiency, response time, leakage rate, pressure drop, and cost efficiency. Each metric provides insights into the valve's operational excellence, ensuring reliable performance in hydraulic systems.