Leave Your Message

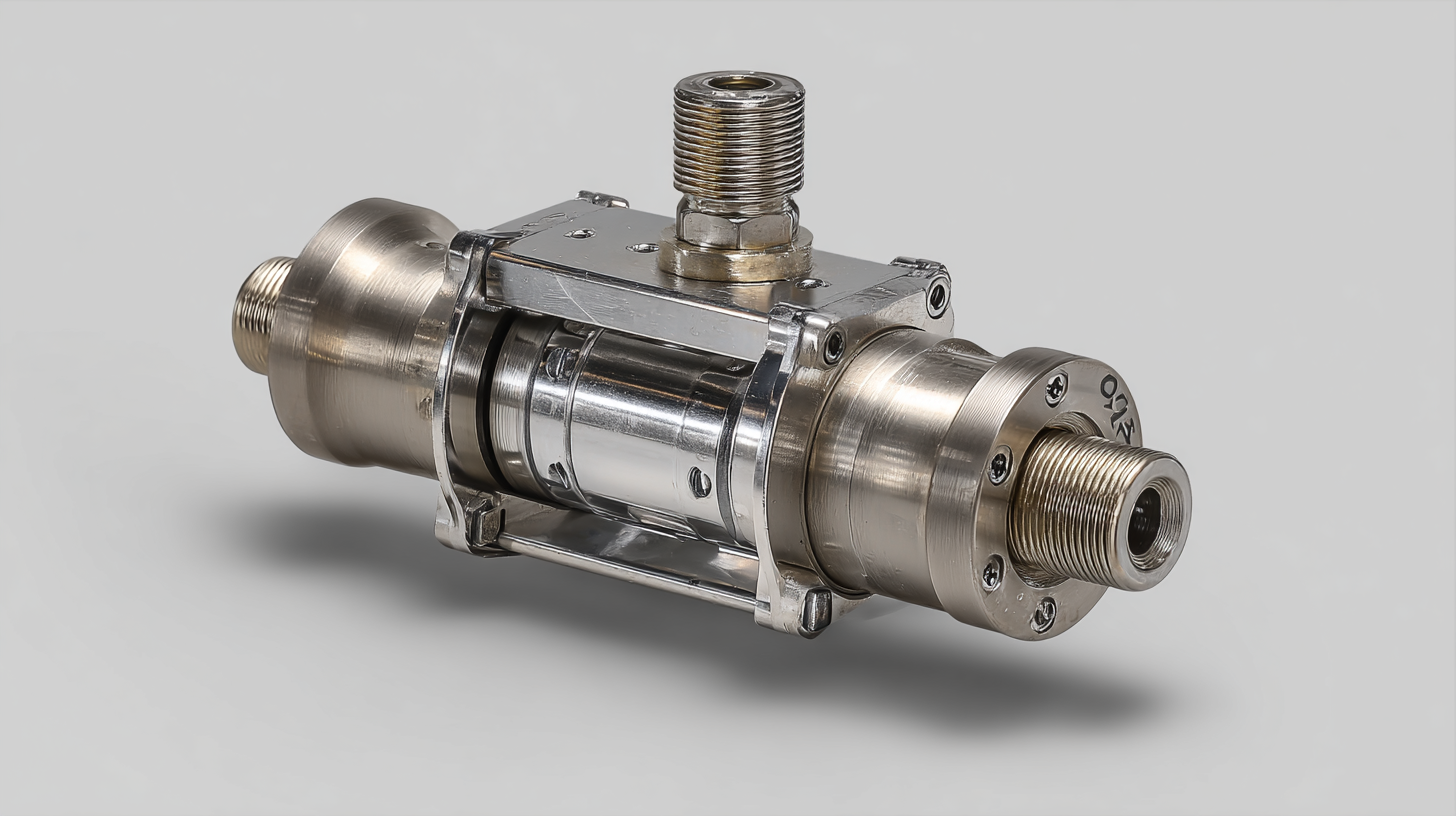

In industrial hydraulic systems, ensuring the optimal functionality of components is crucial for maintaining efficiency and safety. One vital component often overlooked is the Pilot Operated Check Valve, which plays a pivotal role in controlling the flow and preventing backflow within a system. This valve uses a pilot signal to dictate its operation, allowing for precise control over fluid movement, which is essential for the performance of actuators and other hydraulic devices. However, like any mechanical component, Pilot Operated Check Valves can be susceptible to wear, contamination, and improper installation. To maximize their efficiency and reliability, it's imperative to understand the best practices for their installation and maintenance. In this guide, we will explore essential strategies and considerations to ensure that Pilot Operated Check Valves function optimally within your hydraulic systems, thereby enhancing overall operational performance and extending the lifespan of your equipment.

When selecting pilot operated check valves, understanding the specific demands of your system is crucial to enhancing efficiency. According to a report by the Valve Manufacturers Association, improperly chosen valves can lead to a 20-30% increase in energy consumption within hydraulic systems. The principal factors to consider include the pressure ratings, flow rates, and the compatibility of the valve materials with your fluid types. Ensuring that the valve can withstand the operational pressures not only ensures safety but also prolongs the life of the valve and the entire system.

Another essential practice is to evaluate the operational environment of your system. The Hydraulic Institute suggests that selecting valves with appropriate sealing technologies can reduce leakage by more than 70%, significantly improving system reliability and performance. Additionally, opting for valves with integrated pilot control can facilitate faster response times and adaptability in dynamic applications. By meticulously assessing these parameters during the selection process, one can effectively enhance system efficiency and ensure optimal functionality of pilot operated check valves.

Pilot operated check valves (POCVs) are crucial in hydraulic systems, ensuring unidirectional flow and preventing backflow. The reliability of these valves is influenced by several key factors, which can significantly affect performance across various applications. According to a recent report by the Hydraulic Institute, improper installation has been cited as a leading cause of valve malfunction, accounting for nearly 30% of operational failures. Therefore, thorough installation training and adhering to precise specifications are essential to ensure optimal functionality.

Another critical factor is the quality of materials used in the construction of pilot operated check valves. A study by the International Journal of Fluid Mechanics highlighted that valves manufactured from high-grade materials exhibited a 15-20% increase in lifespan compared to those made from lower quality alternatives. Additionally, regular maintenance is vital; neglecting routine checks can result in a cumulative failure rate of 25% over time. Implementing strict maintenance schedules and utilizing advanced monitoring technologies can enhance the overall reliability and efficiency of POCVs in various industrial applications.

| Parameter | Description | Impact on Reliability | Recommended Action |

|---|---|---|---|

| Fluid Type | Type of fluid passing through the valve (oil, water, air) | Certain fluids can cause corrosion or wear | Use materials compatible with the fluid type |

| Operating Pressure | Pressure levels at which the valve operates | High pressures can lead to failure if not rated correctly | Select valves rated for higher pressure than expected |

| Temperature | Operating temperature range | Extreme temperatures can affect performance | Use temperature-resistant materials and seals |

| Installation Orientation | Positioning of the valve in the system | Incorrect orientation might lead to malfunction | Follow manufacturer's guidelines for installation |

| Maintenance Frequency | Regular checks and servicing of the valve | Infrequent maintenance can lead to unexpected failures | Establish a regular maintenance schedule |

Pilot operated check valves are essential components in hydraulic systems, providing controlled flow and preventing backflow. To ensure their optimal functionality and extend their lifespan, regular maintenance is crucial. One effective strategy is to maintain clean hydraulic fluid. Contaminants can accelerate wear on the valve's moving parts, leading to failures. Implementing a robust filtration system and regularly changing the fluid can minimize these risks.

Another important maintenance practice is to routinely inspect the valves for signs of wear or improper operation. This includes checking for leaks, unusual noises, or asymmetrical operation that could indicate internal damage. Timely identification of such issues allows for prompt corrective action, reducing the chance of more serious problems arising. Additionally, ensuring that the pilot control pressure is within the recommended range can enhance the performance of the check valve, preventing unnecessary strain on its components and promoting longevity. Regular training for personnel on these maintenance procedures can also ensure that the systems operate efficiently and reliably.

Pilot operated check valves are critical components in hydraulic and pneumatic systems, designed to prevent backflow while allowing fluid to pass in one direction. Understanding the internal pressure and flow dynamics is essential for ensuring their optimal performance. According to a report by the Hydraulic Institute, proper pressure differential across the pilot valve can enhance the responsiveness and reliability of these valves by up to 30%, significantly reducing the potential for cavitation or valve chatter, which can lead to system inefficiencies.

Pilot operated check valves are critical components in hydraulic and pneumatic systems, designed to prevent backflow while allowing fluid to pass in one direction. Understanding the internal pressure and flow dynamics is essential for ensuring their optimal performance. According to a report by the Hydraulic Institute, proper pressure differential across the pilot valve can enhance the responsiveness and reliability of these valves by up to 30%, significantly reducing the potential for cavitation or valve chatter, which can lead to system inefficiencies.

Flow dynamics also play a pivotal role in the efficacy of pilot operated check valves. Research from the American Society of Mechanical Engineers indicates that maintaining an even flow rate is crucial; variations can cause turbulence that negatively affects the valve’s seating and ultimately its sealing efficiency. An optimal flow rate minimizes the chances of sediment or particulate accumulation, which can impair operation. Therefore, monitoring the internal pressure relative to the flow rate through real-time data analytics can result in more predictable valve behavior and overall system reliability. Implementing these best practices can contribute to extending the lifespan of equipment and minimizing maintenance costs.

When it comes to the installation of pilot operated check valves in industrial settings, avoiding common mistakes is crucial for ensuring optimal functionality. A recent pilot project in Trichy highlights the importance of proper valve installation for maintaining a reliable water supply. Such projects reinforce the need for careful adherence to installation protocols.

One of the primary mistakes in the installation of pilot operated check valves is improper orientation. Ensuring that the valve is installed in the correct direction is vital for its performance. Moreover, inadequate sealing during installation can lead to leaks, compromising the system’s integrity. As seen in Trichy's project, meticulous planning and execution can prevent these issues, ensuring a seamless operation of the water distribution system.

**Tips:** Always double-check the valve's orientation against manufacturer specifications before installation. Use appropriate sealing materials and techniques to enhance the reliability of the connections. Conduct a thorough inspection post-installation to identify and rectify any potential issues before operation begins. By following these guidelines, you can significantly improve the performance and longevity of your pilot operated check valves.