Leave Your Message

In the dynamic landscape of hydraulic systems, the role of Pipe Counterbalance Valves has become increasingly pivotal. As projected by the 2025 industry report from the International Fluid Power Society, the global market for hydraulic components is anticipated to reach $60 billion, with counterbalance valves playing a crucial role in enhancing system efficiency and safety. These valves are essential for preventing uncontrolled movement in hydraulic cylinders, thereby ensuring optimal performance and longevity of machines.

As industries prioritize reliability and energy efficiency, mastering the selection and optimization of Pipe Counterbalance Valves is vital. This comprehensive tutorial will delve into best practices, technical specifications, and strategies to maximize performance, aiming to equip professionals with the necessary tools to navigate this critical aspect of hydraulic system design.

Pipe counterbalance valves play a crucial role in hydraulic systems by maintaining control over load movements and offering stability during operation. These valves are specifically designed to prevent unintended movement of loads by holding them in a fixed position when pressure is applied. This functionality is particularly essential in applications involving heavy machinery, where sudden load drops can pose significant safety risks. By acting as a brake, pipe counterbalance valves help to control the descent speed of heavy loads, ensuring smoother operations and enhancing the longevity of hydraulic components.

Pipe counterbalance valves play a crucial role in hydraulic systems by maintaining control over load movements and offering stability during operation. These valves are specifically designed to prevent unintended movement of loads by holding them in a fixed position when pressure is applied. This functionality is particularly essential in applications involving heavy machinery, where sudden load drops can pose significant safety risks. By acting as a brake, pipe counterbalance valves help to control the descent speed of heavy loads, ensuring smoother operations and enhancing the longevity of hydraulic components.

In addition to safety, understanding the functionality of these valves leads to more efficient system performance. By integrating counterbalance valves into hydraulic systems, operators can fine-tune the flow and pressure settings to match the specific requirements of their machinery. This not only optimizes performance but also reduces energy consumption and wear on other system components. Selecting the correct counterbalance valve size, pressure rating, and flow characteristics is vital for achieving peak performance and reliability in hydraulic applications. Thus, mastering the intricacies of pipe counterbalance valves is essential for anyone looking to enhance the efficiency and safety of hydraulic systems.

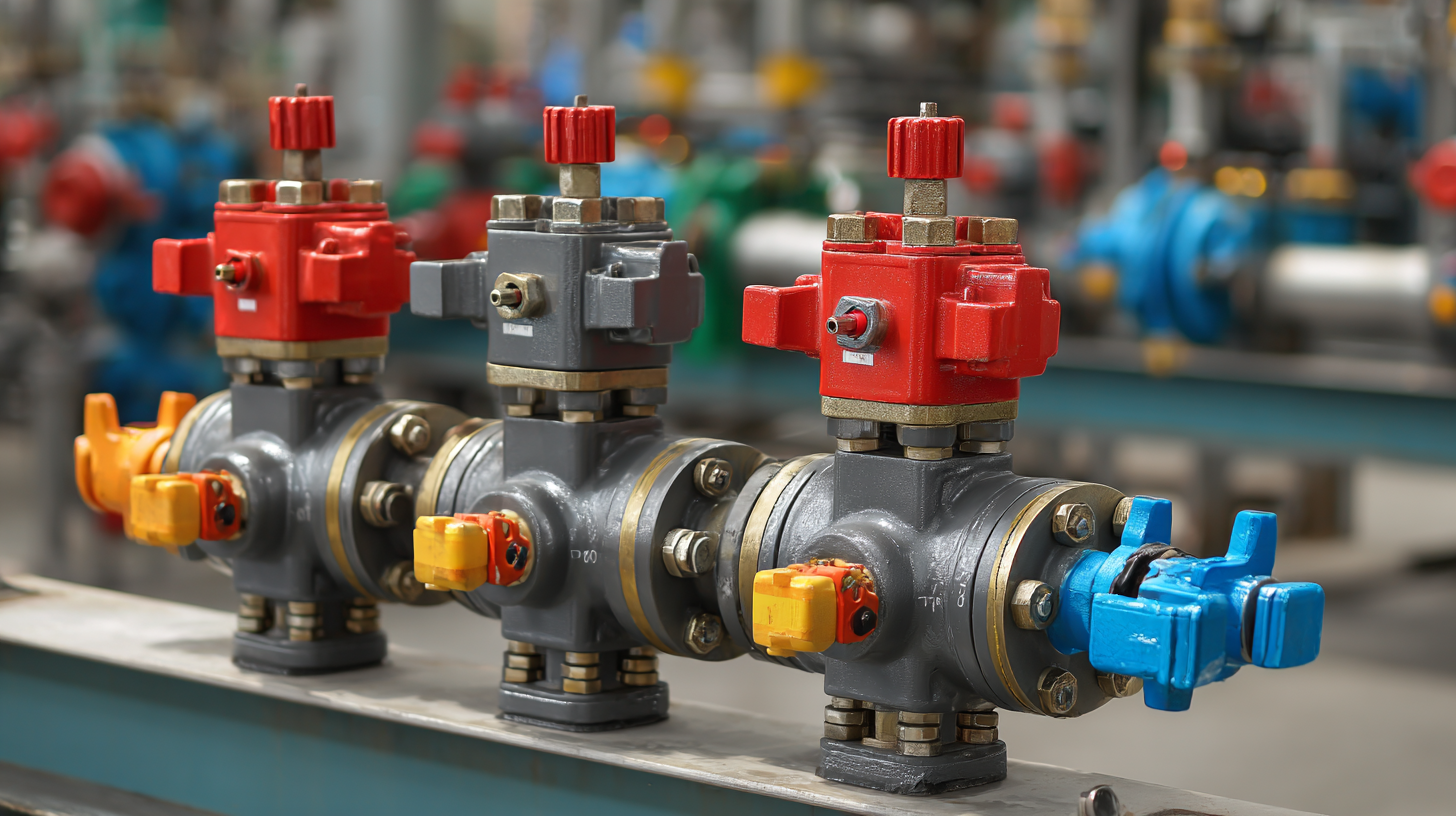

When selecting pipe counterbalance valves, understanding key technical specifications is crucial for optimizing system performance. One of the primary considerations is the pressure rating of the valve. It must align with the operating pressure of the hydraulic system to prevent potential failures. Additionally, the flow rate is another vital specification, as it determines the speed at which hydraulic fluid can travel through the valve. Ensuring that the valve's flow characteristics match the application requirements will help maintain system efficiency and responsiveness.

Another essential aspect to consider is the valve's construction materials. The durability and resistance to corrosion or wear are paramount, especially in harsh environments. Opting for valves made from high-quality materials can lead to a longer service life and reduced maintenance costs. Furthermore, adjustments to control characteristics, such as pressure settings and flow directions, should also be taken into account to tailor the valve's performance to specific operational scenarios. By carefully evaluating these technical specifications, you can select the most appropriate pipe counterbalance valves, ultimately enhancing the overall performance of your hydraulic systems.

Optimizing pipe counterbalance valve performance is crucial for enhancing overall system efficiency in hydraulic applications. These valves play a vital role in maintaining load control and stability in various machinery. To achieve peak performance, it is essential to understand their operational characteristics and how to select the right valve for specific system needs. This includes considering factors such as the flow rate, pressure setting, and the type of hydraulic fluid being used, as these can significantly impact the valve's effectiveness in maintaining system balance.

To further enhance performance, regular maintenance and adjustments are necessary. Ensuring that counterbalance valves are clean and free from debris can prevent operational hiccups that decrease efficiency. Additionally, monitoring system parameters and making real-time adjustments can lead to improved responsiveness and stability. Integrating advanced monitoring technologies can also provide insights into valve performance, allowing for data-driven decisions that optimize the hydraulic system's efficacy. By proactively managing these components, operators can achieve a seamless flow and maximize the productivity of their hydraulic systems.

When dealing with pipe counterbalance valves, several common challenges may arise that can impact the overall performance of hydraulic systems. One significant issue is the risk of uncontrolled movements, as illustrated by recent incidents where machinery operations went awry, leading to costly damages. Operators must ensure that counterbalance valves are properly adjusted and calibrated to prevent sudden drops or erratic movements. Regular maintenance and monitoring can mitigate such risks and enhance system reliability.

Another challenge is the integration with new technological solutions, particularly in sectors like agriculture and data management, where advanced hydraulic components are increasingly deployed. The complexity of modern hydraulic systems necessitates a thorough understanding of the parameters affecting counterbalance operation. Additionally, emerging regulations regarding the use of certain materials present both obstacles and opportunities for design adjustments, compelling manufacturers to innovate while adhering to regulatory standards. Addressing these challenges through effective selection and optimization of counterbalance valves is crucial for achieving peak performance in various applications.

| Challenge | Description | Solution | Impact on Performance |

|---|---|---|---|

| Inadequate Sizing | Selecting a valve that is not properly sized can lead to inefficient operation. | Use pressure drop calculations and flow rate specifications to determine the correct valve size. | Improved efficiency and reduced energy consumption. |

| Leakage Issues | Leaks can occur due to wear on seals and improper installation. | Regular maintenance and using high-quality seals to prevent leaks. | Enhanced system reliability and reduced maintenance costs. |

| Temperature Fluctuations | Extreme temperature changes can affect valve performance. | Choose valves that are rated for high and low-temperature ranges. | Consistent performance across varying environmental conditions. |

| Installation Errors | Incorrect installation can lead to imbalanced loads and valve failure. | Follow manufacturer guidelines and ensure proper training for technicians. | Maximized operational safety and valve longevity. |

| Improper Adjustments | Misconfigured settings can lead to jolting or slow response. | Regularly check and adjust settings based on application requirements. | Optimized control and smoother operation. |

When it comes to pipe counterbalance valves, proper installation and maintenance are crucial for ensuring optimal performance and longevity. According to the Fluid Power Journal, a significant 30% of hydraulic system failures are attributed to improper installation techniques. To mitigate such risks, it is essential to follow best practices, such as ensuring that the valve is installed in the correct orientation and securely fastened to prevent any unwanted movement during operation. Additionally, using high-quality sealing materials can significantly reduce the potential for leaks, enhancing system reliability.

Regular maintenance is another key aspect that cannot be overlooked. The International Fluid Power Society states that implementing a preventive maintenance schedule can extend the lifespan of hydraulic components by up to 50%. Key maintenance practices include routine inspections for wear and tear, cleaning or replacing filters, and monitoring the valve performance for any signs of inefficiency. Incorporating these best practices not only safeguards the integrity of the hydraulic system but also contributes to achieving peak performance, ensuring that your operations run smoothly and effectively.