Leave Your Message

In the fast-evolving landscape of industrial automation, the importance of reliable components cannot be overstated, with the Pilot Operated Check Valve emerging as a pivotal element in various hydraulic systems. As per recent industry reports, the global market for check valves is projected to grow significantly, with an anticipated CAGR of over 5% from 2021 to 2027. This growth is driven by the increasing demand for efficient and safe fluid control solutions across sectors such as manufacturing, oil and gas, and water treatment. Notably, manufacturers in China are setting benchmarks in quality and innovation, positioning themselves as leading exporters of the best Pilot Operated Check Valves worldwide. This blog will delve into the detailed technical parameters of these valves and provide a comprehensive tutorial on their functionality, ensuring that professionals in the field can make informed decisions that optimize both performance and reliability in their operations.

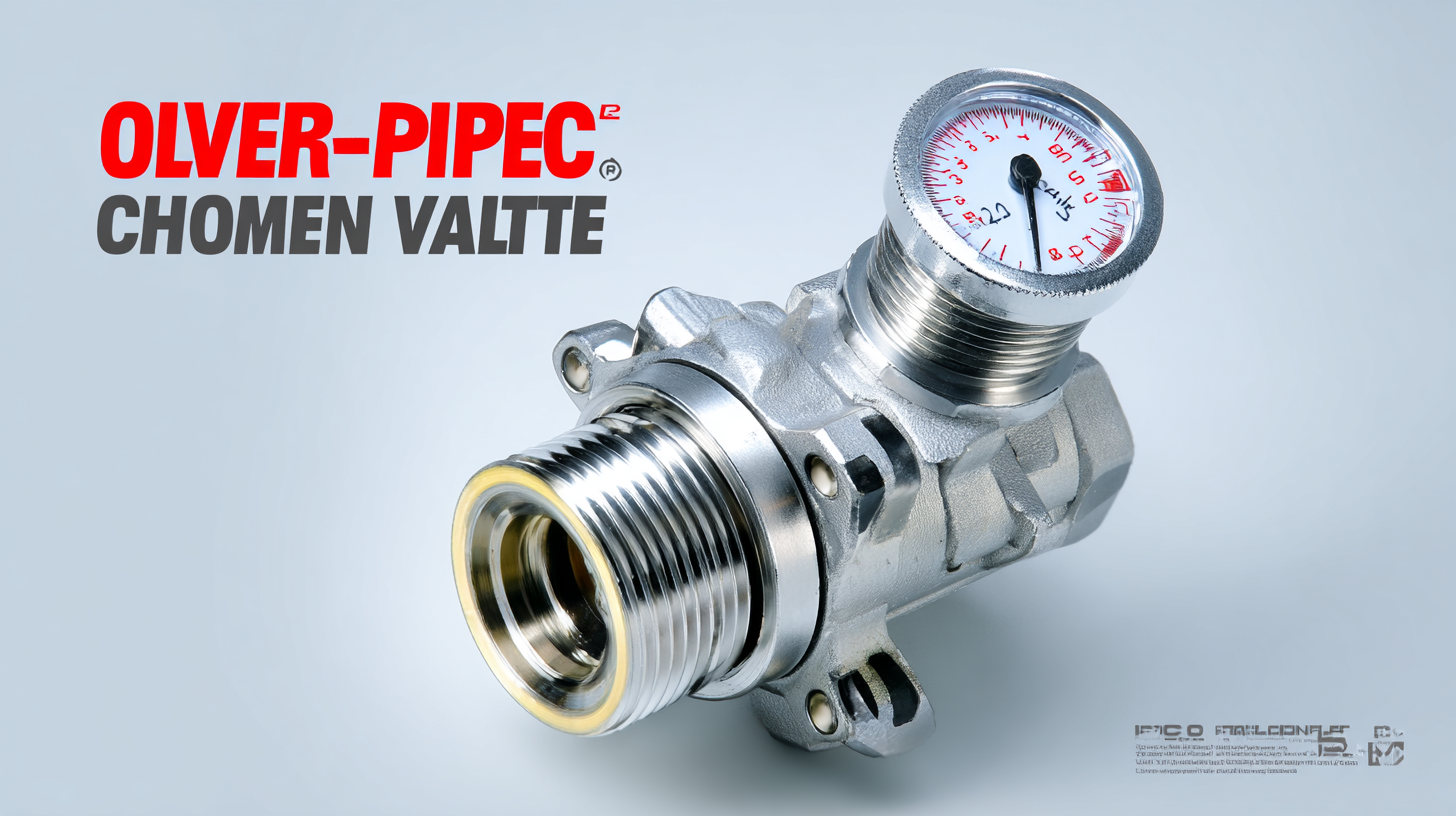

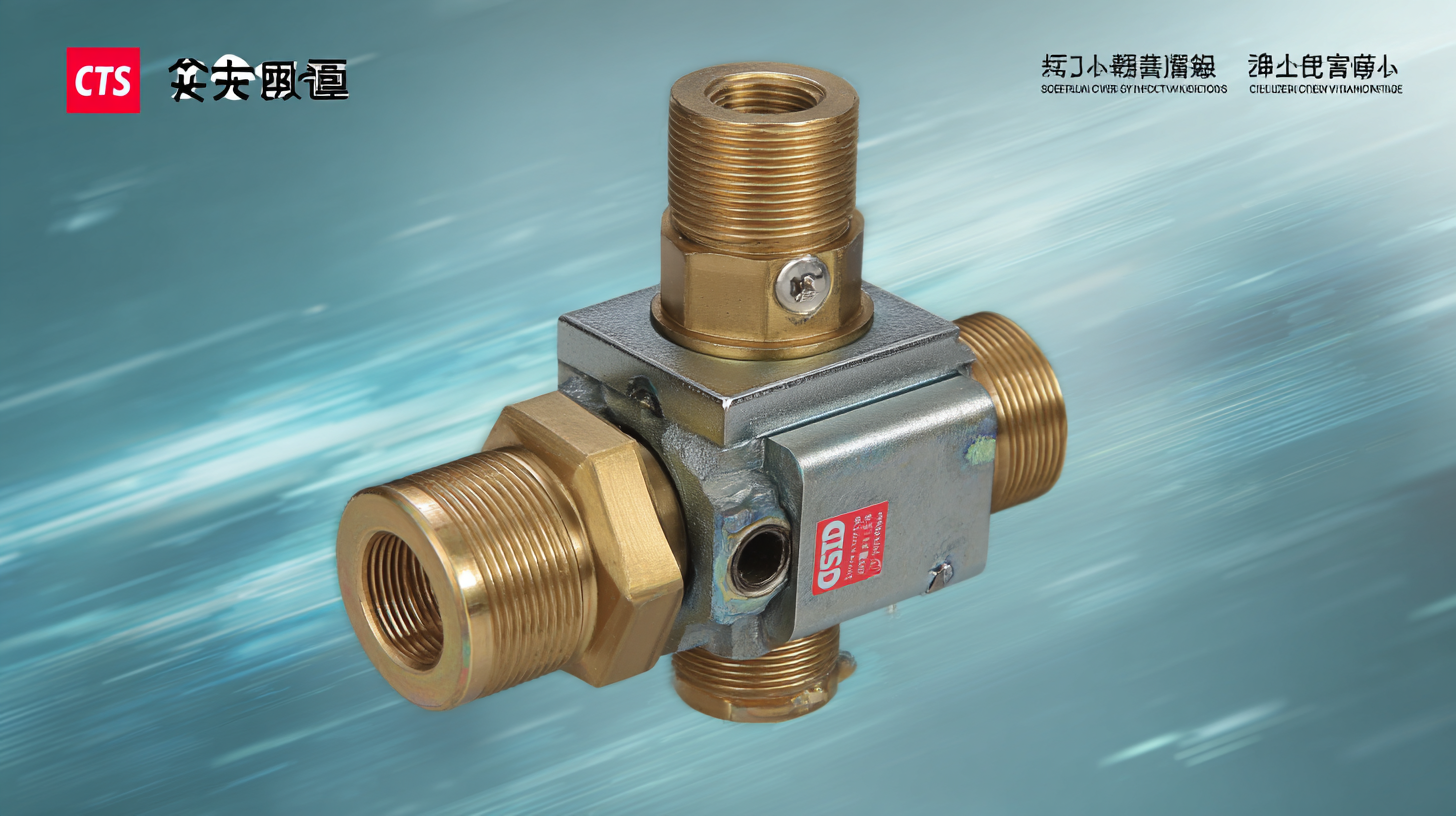

Pilot operated check valves play a crucial role in various industrial applications, ensuring effective flow control and preventing backflow in hydraulic systems. These valves are particularly beneficial in setups where pressure differentials are present, allowing fluids to flow in one direction while blocking reverse flow. This functionality is essential in maintaining system integrity and efficiency, especially in demanding environments like manufacturing plants, construction sites, and marine operations.

When selecting a pilot operated check valve, it's important to consider several factors. Firstly, ensure the valve's materials are compatible with the fluids in your system to avoid corrosion and failure. Secondly, pay attention to the pressure rating and flow capacity to ensure optimal performance. Lastly, regular maintenance is key; inspect the valves periodically for wear and tear, as this can prevent unexpected downtime and costly repairs.

Another tip is to invest in high-quality valves from reputable manufacturers. This can significantly reduce the likelihood of malfunctions and extend the lifespan of your equipment. Look for certifications and performance data to guide your purchase decisions, ensuring that you choose a valve that meets the specific needs of your application.

The manufacturing process of pilot operated check valves in China has evolved significantly over the years, fueled by advances in technology and stringent quality control measures. According to a recent report by MarketsandMarkets, the global check valve market is expected to reach USD 4.23 billion by 2025, which highlights the growing demand and the role that skilled manufacturers in China play on the international stage.

In the production of these valves, precision machining and assembly techniques are critical. The use of computer numerical control (CNC) machines allows for improved accuracy and efficiency in creating the intricate components of pilot operated check valves. Additionally, rigorous testing protocols are enforced to ensure that these devices can withstand varying pressures and flow conditions, which is vital for applications in industries such as oil and gas, water management, and manufacturing.

Tips for manufacturers aiming to compete effectively in the global market include investing in R&D to innovate products tailored to specific client needs, as well as adopting lean manufacturing practices to optimize operational efficiency. Furthermore, establishing robust quality assurance processes not only meets international standards but also strengthens customer trust and loyalty.

When it comes to the production of pilot-operated check valves, securing the right export certifications is crucial for manufacturers aiming to expand their global market presence. Key certifications such as ISO 9001 ensure that manufacturers adhere to strict quality management systems, which not only enhance operational efficiency but also build trust with international clients. Additionally, certifications like CE, which demonstrate compliance with European safety and environmental regulations, are essential for manufacturers looking to enter European markets.

Moreover, industry-specific certifications such as API (American Petroleum Institute) and ASME (American Society of Mechanical Engineers) can further distinguish a manufacturer’s products in competitive markets. These certifications serve as a testament to the reliability and performance standards of check valves, particularly in demanding applications like oil and gas, water treatment, and industrial processing. By obtaining these essential certifications, Chinese manufacturers of pilot-operated check valves can position themselves as leading suppliers in the global market, appealing to clients seeking quality and reliability.

When selecting a pilot operated check valve, it is essential to grasp the specific operational requirements of your system. According to recent industry reports, improper selection can lead to increased downtime and maintenance costs, which can affect overall productivity. A properly chosen pilot operated check valve can enhance pressure management within fluid systems, ensuring optimal performance and efficiency. Data indicates that a well-implemented valve system can reduce energy consumption by up to 20%, underlining the importance of considering both operational parameters and overall system characteristics during selection.

Factors to consider include flow rate, pressure requirements, and compatibility with the fluids handled. Industry experts recommend utilizing engineering best practices such as simulation tools to predict system behavior under various conditions. These tools can help determine the most suitable specifications for the check valve, ultimately leading to better performance and reduced operational risks. In conclusion, selecting the right pilot operated check valve involves a comprehensive approach that integrates technical knowledge and strategic analysis to align with your unique operational needs.

| Valve Type | Size (inches) | Pressure Rating (psi) | Material | Port Connection | Warranty Period |

|---|---|---|---|---|---|

| Pilot Operated Check Valve | 1 | 150 | Cast Iron | Flanged | 2 Years |

| Pilot Operated Check Valve | 2 | 300 | Stainless Steel | Threaded | 3 Years |

| Pilot Operated Check Valve | 3 | 600 | Brass | Compression | 1 Year |

| Pilot Operated Check Valve | 4 | 400 | PVC | Socket Weld | 2 Years |

The global demand for pilot operated check valves, particularly those manufactured in China, is witnessing significant growth. As highlighted in recent market research, the Global Sanitary Pumps and Valves Market is projected to be worth USD 3.1 billion by 2033, growing at a 3.7% compound annual growth rate (CAGR). This trend underscores the increasing reliance on high-quality, efficient valve solutions across multiple industries worldwide.

One driving factor behind this expansion is the emphasis on maintaining hygienic standards in various sectors, including food processing and pharmaceuticals. As industries strive for compliance with strict regulations, the demand for reliable check valves that ensure operational integrity and safety will continue to rise.

Tips: When choosing pilot operated check valves, consider factors such as compatibility with specific fluids, pressure ratings, and maintenance requirements to ensure optimal performance. Additionally, staying informed about global market trends can help businesses make strategic decisions that align with consumer needs and technological advancements. Utilizing suppliers with a robust export capacity can further enhance supply chain efficiency.