Leave Your Message

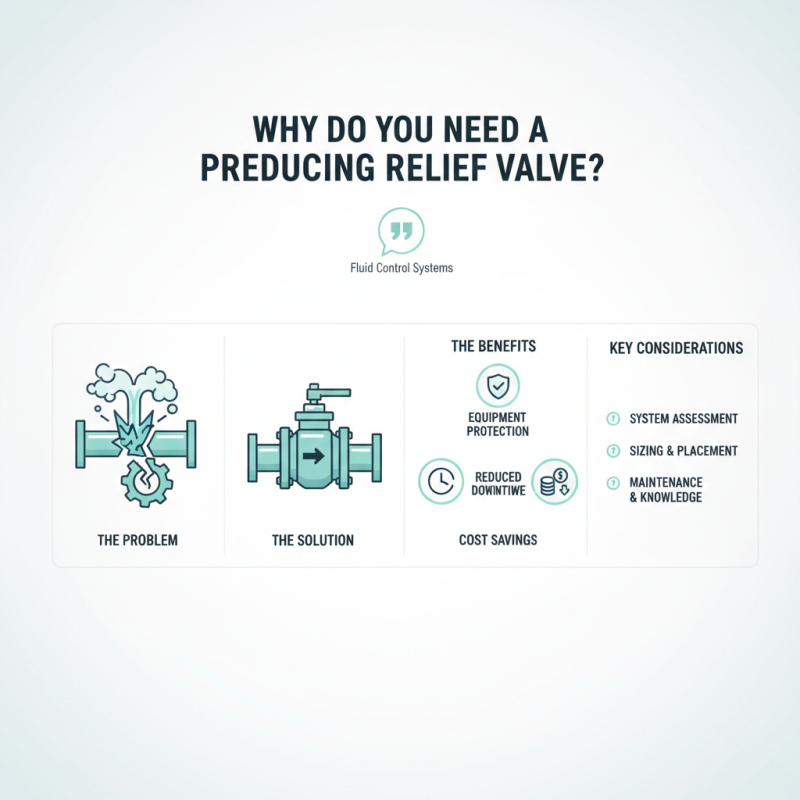

In the realm of fluid control systems, the importance of a Pressure Reducing Relief Valve cannot be overstated. As John Smith, a seasoned engineer in the field, states, "A Pressure Reducing Relief Valve is essential for maintaining safe operational pressures." This device plays a crucial role in protecting equipment from pressure surges that could lead to catastrophic failures.

Using a Pressure Reducing Relief Valve allows facilities to manage pressure more effectively. It ensures that the pressure remains within safe limits, preventing damage to pipelines and machinery. Consequently, operators can avoid costly repairs and downtime. However, many overlook the need for this safety device, leading to potential risks. Ignoring its importance can result in serious consequences.

It's crucial to remember that all systems are different. Businesses must assess their unique requirements carefully. The decision to implement a Pressure Reducing Relief Valve should not be taken lightly. Questions about sizing, placement, and maintenance arise. Proper knowledge and planning can mitigate shortcomings. Failure to recognize these factors might lead to operational inefficiencies and safety hazards.

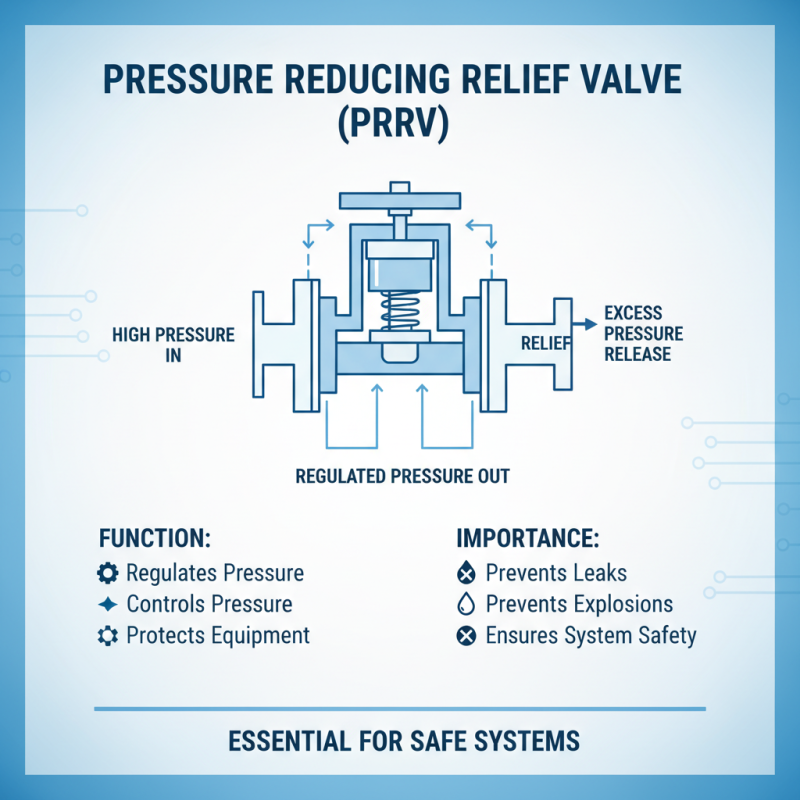

A pressure reducing relief valve (PRRV) plays a crucial role in maintaining safe pressure levels in various systems. By regulating and controlling pressure, it protects equipment from damage. Excess pressure can lead to leaks or even explosions, so understanding how these valves work is essential.

When pressure in a system exceeds a set limit, the PRRV activates. It then diverts excess pressure away, ensuring safe operation. This function not only saves equipment but also enhances safety for users. Regular maintenance is necessary to ensure the valve functions correctly. Neglecting this can lead to unexpected failures.

**Tip:** Always check the settings on your PRRV. Adjusting them can improve efficiency and safety.

The design of a pressure reducing relief valve is often quite specialized. Some may find themselves unsure about proper installation. Improper installation can lead to system malfunctions or potential hazards. Understanding the specifications of the valve can prevent costly issues down the line.

**Tip:** Consult the manufacturer's guidelines for installation. Following recommended practices helps avoid common errors.

Pressure relief valves are crucial for system safety. They help manage excessive pressure in various applications, from boilers to piping systems. Without them, equipment may fail. This can lead to leaks or even catastrophic explosions. Ensuring these valves are functioning correctly is essential for preventing dangerous situations.

Regular maintenance is often overlooked. Many facilities neglect routine checks of pressure relief valves. This oversight can have serious consequences. A failed valve might not relieve pressure when needed. Operators should implement a schedule for inspecting these devices. This can help identify issues before they escalate.

Education on pressure relief systems is vital. Understanding their importance is key to safety. Employees should know how to operate and monitor these valves. It is not just about compliance; it’s about protecting lives. Effective training can reduce risks and improve overall system reliability.

| Feature | Description | Importance | Example Applications |

|---|---|---|---|

| Pressure Control | Regulates system pressure to a safe level | Prevents equipment damage and system failures | Boilers, compressors |

| Safety Mechanism | Acts as a fail-safe to release excess pressure | Ensures personnel safety and equipment integrity | Chemical processing, oil and gas |

| Compliance Standards | Meets regulatory requirements for pressure systems | Avoids legal issues and fines | Manufacturing, pharmaceuticals |

| Cost Efficiency | Minimizes costly downtime and repairs | Saves money by preventing accidents | Power generation, water treatment |

Pressure reducing relief valves play a crucial role in fluid systems. They maintain optimal pressure levels, preventing damage from excessive pressure. According to industry reports, around 20% of equipment failures result from overpressure conditions. These failures can lead to significant downtime and costly repairs.

The functioning of a pressure reducing relief valve is straightforward yet vital. When system pressure surpasses a preset limit, the valve opens to release excess pressure. This action is often swift, ensuring safety and system integrity. Data shows that systems equipped with these valves experience a 30% reduction in failure rates. Their design allows for continuous monitoring and adjustment, making them essential in various applications.

However, not all systems are designed optimally. Some valves may fail due to corrosion or debris buildup. Regular maintenance is necessary but often overlooked. According to studies, nearly 15% of valves inspected show signs of wear. This raises questions about system reliability and long-term planning. Ensuring proper installation and routine checks can help mitigate these issues.

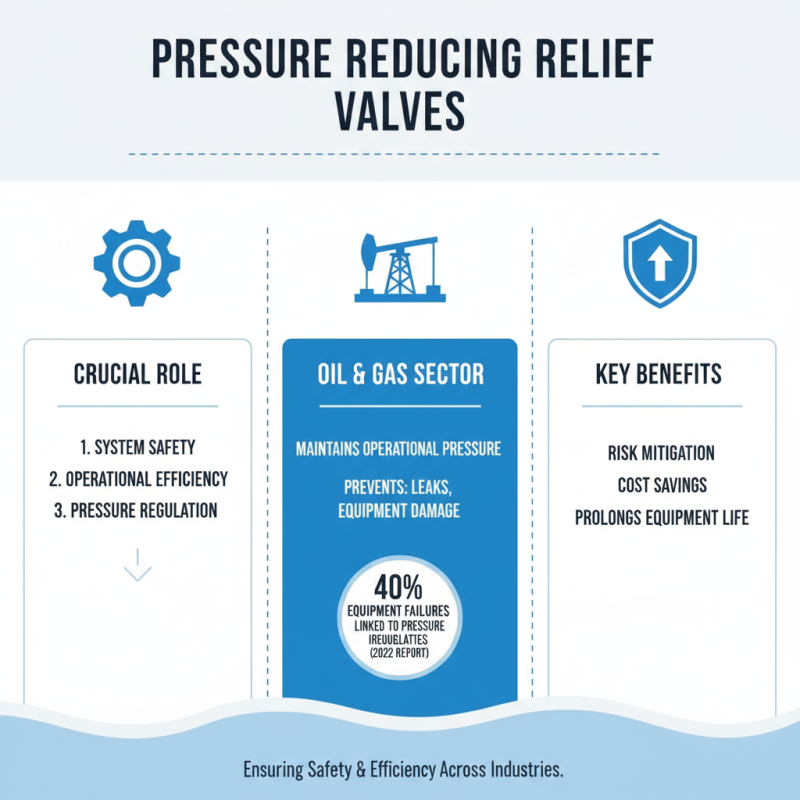

Pressure reducing relief valves play a crucial role across various industries. They ensure that systems operate safely and efficiently under varying pressure conditions. For instance, in the oil and gas sector, these valves help maintain operational pressure, preventing costly leaks and equipment damage. According to a 2022 report, nearly 40% of equipment failures in this sector are linked to pressure irregularities.

In the water treatment industry, these valves regulate pressure to optimize flow rates. A study showed that improper pressure can lead to a 20% reduction in system efficiency. By utilizing pressure reducing relief valves, facilities can save on energy costs and improve overall performance. Regular maintenance checks are essential. These checks can identify any wear or tear that may compromise safety.

Tips: Always consult with industry experts during installation. An improperly sized valve can expose the system to unnecessary risks. Monitor your systems frequently. Unanticipated pressure spikes can lead to significant damage. Striking a balance between pressure settings is key.

Pressure reducing relief valves play a vital role in maintaining safe and efficient operations in various systems. However, they can face several issues that may lead to malfunction or inefficiency. Regular maintenance is crucial for optimal performance and longevity.

Common issues include leaks, noise, and failure to maintain pressure. Leaks can result from worn seals or improper installation. Noise might indicate issues with internal components or excessive pressure. It's important to address these immediately to prevent further complications.

Tips for maintaining pressure reducing relief valves involve regular inspections and timely replacements. Check seals for wear and tear at least quarterly. Regularly test the valve's functionality. This can ensure it operates at the required pressure. Keep an eye on the overall system. Sometimes, problems in interconnected components can affect the valve. Lastly, document any maintenance activities. This helps identify recurring issues over time.