Leave Your Message

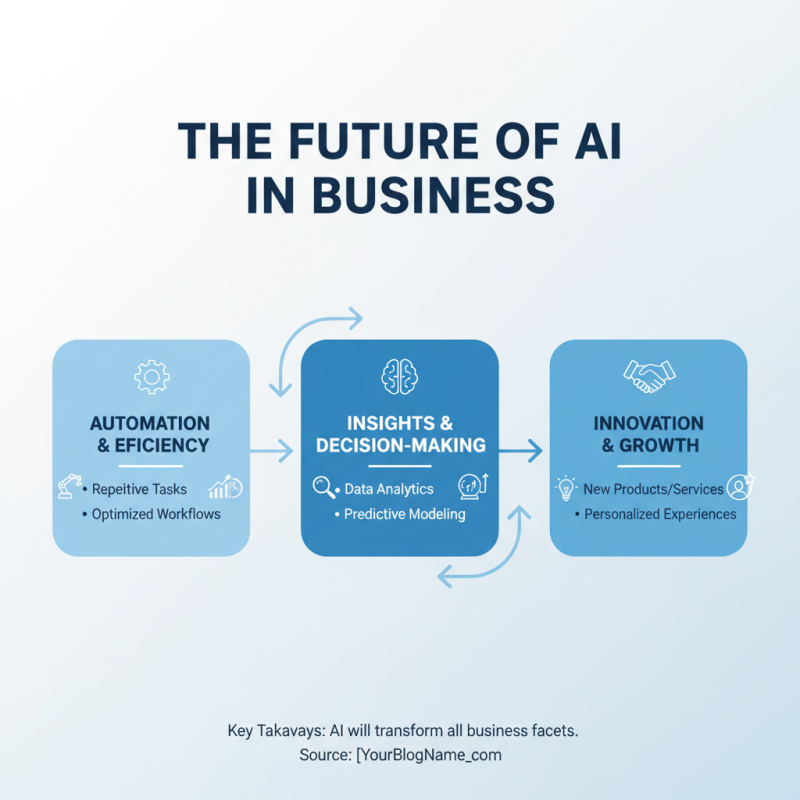

In the realm of fluid control systems, the importance of choosing the right Directional Logic Element Valves cannot be overstated. According to a recent report by the International Fluid Power Society, over 70% of hydraulic failures can be traced back to incorrect valve selection. This underscores the critical role these valves play in ensuring system efficiency and reliability. Industry expert James R. Thompson states, "Optimizing valve selection is not just about performance; it's about safety and longevity."

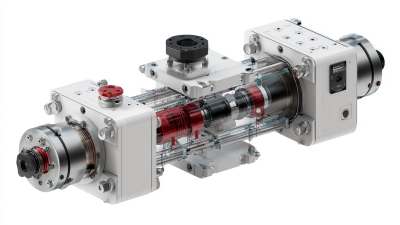

Directional Logic Element Valves serve as vital components in directing fluid flow based on specific functional requirements. Their applications range from manufacturing to mobile machinery. As projects evolve, engineers face the challenge of selecting valves that meet stringent operational criteria. For instance, variations in pressure, flow rate, and environmental conditions can significantly impact performance.

However, navigating the myriad options available can be daunting. Some professionals may overlook essential features, leading to potential system inefficiencies. The challenge lies in balancing functionality and cost-effectiveness while ensuring compliance with industry standards. The dynamic nature of project requirements adds another layer of complexity. Reflection on past experiences is necessary for making informed decisions in future projects.

Directional logic element valves play a crucial role in fluid control systems. Their main function is to direct the flow of liquids or gases within a circuit. This capability allows for precise control in various applications, from industrial machinery to automated systems. According to a recent industry report, the global market for these valves is projected to reach $7 billion by 2025, highlighting their growing significance in modern engineering.

Understanding their functions is essential for successful integration into projects. These valves can switch flow paths, change directions, and manage pressure levels. A study indicates that inefficiencies in valve selection can lead to 15% higher operational costs in industrial settings. Opting for the wrong type may cause unexpected downtime. Even the most detailed designs can fall short if these components do not align with system requirements.

When choosing these valves, consider factors like response time, flow rate, and pressure rating. The wrong choice can yield suboptimal performance. Reports show that 20% of system failures are linked to inappropriate valve selection. This underscores the importance of thorough research and testing. Relying on assumptions can lead to errors that ultimately affect project outcomes. Each choice involves a balancing act between performance and cost, making careful evaluation essential.

When selecting directional logic element valves for any project, several factors require careful consideration. One key aspect is the medium being controlled. For instance, the properties of liquids or gases can significantly impact valve performance. The American Society of Mechanical Engineers (ASME) reports that improper valve selection can lead to pressure drops, reducing system efficiency by up to 30%.

Another crucial factor is the valve's operation type. Actuated valves enhance responsiveness, while manual valves may introduce delays. A study by the International Society for Automation highlights that systems using automated valves can increase throughput by 25%. Additionally, the compatibility of materials with the operating environment is vital. Corrosive substances can deteriorate certain materials, necessitating regular inspections and potential replacements.

Moreover, installation space is often underestimated. Tight spaces can limit accessibility for future maintenance. Sometimes, projects compromise on valve size due to design constraints. Yet, this can lead to operational inefficiencies, increasing downtime. A balance must be struck between optimal choice and practical limitations. This self-reflection on design decisions helps in making informed choices that enhance overall system performance.

Directional logic element valves are crucial in various industries. These valves control the flow and direction of fluids in hydraulic and pneumatic systems. They can be classified into several types, including spool valves, poppet valves, and plate valves. Each type has distinct applications, affecting the choice according to project needs.

For example, spool valves are widely used in mobile machinery and manufacturing equipment. They offer precise flow control and can operate multiple actuators. A recent industry report highlighted that spool valves account for around 40% of the valve market as of 2023. Meanwhile, poppet valves are preferred in applications requiring high pressure and compact designs. They are often found in automotive and aerospace sectors, where every space counts.

Despite their advantages, challenges exist. For instance, the incorrect selection of valve types can lead to inefficiencies. An improperly chosen valve might cause energy losses or increased maintenance costs. This highlights the need for careful assessment. Accurate calculations and expert consultations can aid in making informed decisions, ensuring optimal performance in projects.

Directional logic element valves play a critical role in various engineering projects. For optimal performance, installation and maintenance are key factors. A well-installed valve can enhance system efficiency significantly. According to a report by the International Society of Automation, proper installation can improve performance by up to 20%.

Proper positioning is essential. Make sure the valves are aligned correctly. Misalignment can lead to leaks or system failures. Additionally, regular maintenance must not be overlooked. A recent study indicated that 30% of valve issues arise from poor maintenance practices. Check seals and connections frequently. Lack of attention to small details can result in costly interruptions.

Cleaning is also crucial. Debris accumulation can affect valve function. It’s important to establish a routine cleaning schedule. Sometimes, adjustments may be necessary to ensure valves operate smoothly. Ignoring small problems today can lead to significant challenges later. Ensuring proper care can actually save time and money in the long run.

| Valve Type | Port Size | Max Pressure (psi) | Material | Applications | Maintenance Frequency |

|---|---|---|---|---|---|

| Solenoid Valve | 1/4" | 150 | Brass | Automotive | Every 6 months |

| Pneumatic Valve | 3/8" | 200 | Aluminum | Industrial Automation | Annually |

| Hydraulic Valve | 1/2" | 3000 | Steel | Construction Machinery | Quarterly |

| Check Valve | 1" | 250 | PVC | Water Supply Systems | Every 2 years |

When choosing directional logic element valves, common mistakes can lead to project delays. One frequent error is underestimating the required flow rate. According to industry reports, a flow rate miscalculation can reduce system efficiency by up to 30%. This impacts overall performance, causing unnecessary wear on components.

Another pitfall is overlooking compatibility with existing systems. Engineers may assume new valves will fit without proper analysis. A mismatch can result in leaks and malfunctions, jeopardizing safety. Studies show that improper installations increase maintenance costs by 40%. These oversights can derail projects and inflate budgets.

Inadequate attention to environmental conditions is also a mistake. Valves must endure specific temperatures and loads. Ignoring these factors can cause premature failures. Data indicates that environmental miscalculations can lead to a 25% increase in downtime. Assessing these elements carefully ensures project resilience and longevity.