Leave Your Message

The selection of the right Manual Check Valve is critical in ensuring efficiency and reliability in fluid control systems. According to a report by the Global Market Insights, the demand for check valves, specifically manual types, is expected to witness significant growth, driven by increasing investments in water and wastewater treatment and industrial infrastructure development. Manual check valves play a vital role in preventing backflow and maintaining system integrity, which is essential in industries ranging from oil and gas to pharmaceuticals.

However, with a myriad of choices available in the market, selecting the appropriate manual check valve can be daunting. Understanding the specific requirements of your application, including flow rate, pressure, and fluid characteristics, is essential in making an informed decision that aligns with industry standards and enhances operational efficiency. This guide aims to provide insights on effectively choosing the right manual check valve that meets your needs, ensuring optimal performance in your systems.

Manual check valves are essential components in various fluid systems, designed to prevent backflow while allowing fluid to flow in one direction. Understanding their basic function is crucial for anyone involved in system design or maintenance. A manual check valve typically features a disc that opens when fluid flows in the intended direction and closes when flow reverses, thereby blocking potential backflow. This function is vital in applications where maintaining the direction of fluid flow is necessary to protect equipment and ensure system efficiency.

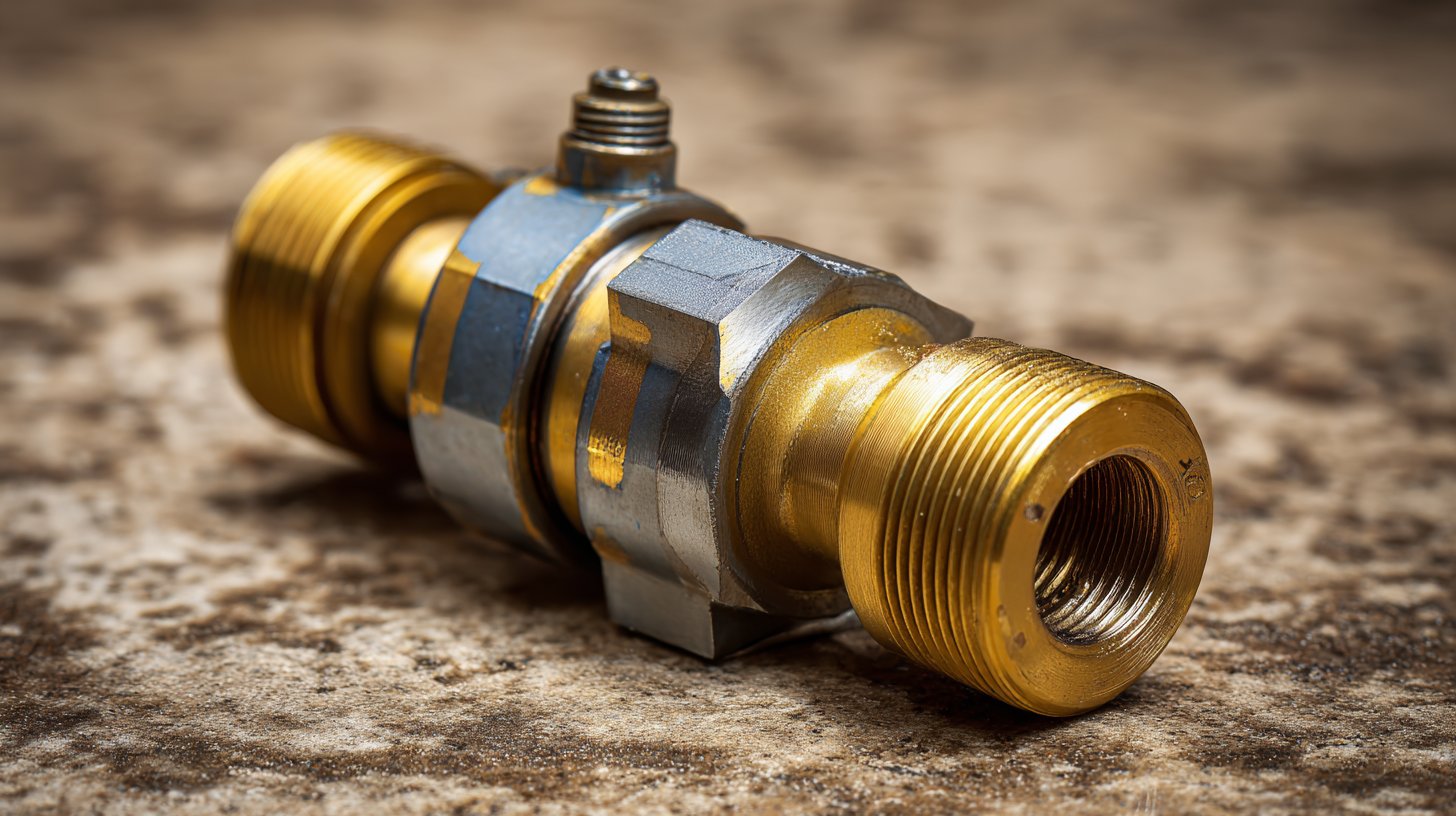

There are different types of manual check valves, including swing check valves and lift check valves, each serving specific operational needs. Swing check valves operate with a hinge mechanism, providing a tight seal and minimal pressure drop. In contrast, lift check valves use a disc that moves vertically, making them suitable for high-pressure applications. Choosing the right type involves assessing factors such as the medium being transported, operating pressure, and required flow rates. Armed with this foundational knowledge, you can make informed decisions when selecting a manual check valve that aligns with your specific requirements.

When selecting a manual check valve, it's essential to consider several key factors that can significantly impact its performance and suitability for your specific application. One of the foremost aspects to evaluate is the valve's material. Depending on the substance being transported, options such as bronze, stainless steel, or PVC might be more appropriate to resist corrosion, pressure, and temperature variations.

Tips: Always assess the compatibility of the valve material with the fluid, as this will ensure longevity and reliable functionality.

Another crucial factor is the valve's size and connection type. Proper sizing not only helps maintain optimal flow rates but also prevents pressure drops that could affect system efficiency. It's vital to measure existing piping accurately and choose a valve that fits seamlessly.

Tips: When in doubt, consult with a professional or refer to manufacturer specifications to avoid any miscalculations regarding size and connection type.

Additionally, consider the operational environment of the check valve. If it will be exposed to extreme weather conditions or high-stress situations, additional features or robust designs may be necessary.

Tips: Evaluate the application's environment to ensure that the selected valve can withstand conditions like vibration, temperature extremes, or potential chemical exposure.

When selecting a manual check valve, understanding the various types available is essential for meeting your specific application needs. Common types include ball check valves, globe check valves, and swing check valves. Ball check valves are ideal for systems requiring tight sealing and minimal backflow, while globe check valves offer excellent flow regulation and are suitable for higher pressure applications. Swing check valves, on the other hand, are often used in horizontal piping and are effective for large flow volumes.

Tips: Consider the fluid characteristics, such as viscosity and temperature, when selecting your valve type. This will help ensure optimal performance and longevity. Additionally, evaluate the installation location; some valves require more space than others, which could affect your setup.

Another critical aspect is the material of the valve. Common materials include brass, stainless steel, and PVC, each suited for different environments. For instance, stainless steel is preferable in corrosive applications, while PVC is a cost-effective solution for lighter fluids.

Tips: Always check the manufacturer's specifications to ensure compatibility with your system and fluid type. Consulting with industry experts or engineers can also provide valuable insights and enhance your decision-making process.

When installing a manual check valve, it is crucial to ensure that the valve is oriented correctly to allow for proper flow direction. Start by checking the manufacturer’s guidelines, which typically indicate the appropriate installation position. Additionally, it’s essential to choose a location that offers easy access for future maintenance. This can save you significant time and effort when inspections or repairs are required.

Once the valve is installed, regular maintenance is key to optimal performance. Schedule periodic inspections to check for any signs of wear, corrosion, or debris accumulation within the valve. Cleaning the valve periodically can help prevent blockages that reduce efficiency. Furthermore, lubricating moving parts can enhance operation and prolong the life of the valve. By paying close attention to these installation and maintenance tips, you can ensure that your manual check valve operates reliably and effectively throughout its lifespan.

Choosing the right manual check valve can be a daunting task, especially when there are common pitfalls that can lead to suboptimal decisions. One major mistake to avoid is failing to consider the specific application requirements. Each system has unique demands regarding flow rate, pressure, and medium type. Ignoring these factors can result in insufficient performance or even system failure.

Another frequent error is neglecting to verify compatibility with existing equipment. It's crucial to ensure that the valve's dimensions and materials align with your piping system to prevent leaks or damage over time. Additionally, some may overlook the importance of consulting with manufacturers or engineering professionals who can provide insights tailored to your context, similar to how design errors in complex blueprints have been minimized by leveraging technology in engineering. Taking these steps can save you from costly mistakes and ensure the reliability of your system.

| Parameter | Recommended Value | Common Mistakes |

|---|---|---|

| Flow Rate | Match to system requirements | Choosing a valve for a lower flow rate |

| Material | Corrosion-resistant materials for certain applications | Ignoring media compatibility |

| Pressure Rating | Above system pressure requirements | Underestimating pressure surges |

| Size | Fit to pipe diameter | Choosing a valve too large or small |

| End Connections | Match pipe type (threaded, flanged, etc.) | Ignoring connection compatibility |