Leave Your Message

Choosing the right Lifting Platform Hydraulic Valve is crucial for operational efficiency and safety. According to industry expert John Miller, “A single miscalculation in valve selection can lead to costly mistakes.” Selecting the appropriate valve involves understanding its specifications and how it interacts with the lifting platform's hydraulic system.

Consider the load capacity and response time of the Lifting Platform Hydraulic Valve. These factors impact performance and safety. Various models exist, each suited for different applications. It’s essential to match these features with your specific requirements. An improper choice may lead to suboptimal performance or even system failure.

Moreover, pay attention to the valve's compatibility with other components. Incompatible parts can cause delays in operations and increase maintenance costs. Reflecting on this, it’s clear that even small details matter. The choice of a Lifting Platform Hydraulic Valve can determine the effectiveness and reliability of the entire system.

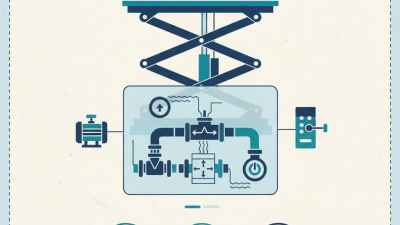

When selecting a lifting platform hydraulic valve, understanding its functionality is crucial. These valves control the flow and pressure of hydraulic fluid, ensuring the smooth operation of lifting platforms. Reports indicate that approximately 70% of operational failures in hydraulic systems are linked to valve issues. That's significant. Flaws in valve design or selection can lead to unexpected downtimes and costly repairs.

Different types of hydraulic valves exist for specific applications. Pressure relief valves protect systems from overload. Directional control valves manage the movement of the platform. Flow control valves regulate speed. Each valve serves a distinct purpose. Analyzing your platform's needs is essential. Misjudging requirements often results in inefficiencies. It’s a common oversight.

During the selection process, consider factors like load capacity and environmental conditions. These influence valve performance and longevity. Industry statistics suggest that improper selection can reduce system efficiency by up to 30%. This impact is not negligible. Regular maintenance and inspections are vital too. Even the best valves can malfunction over time without proper care. Making informed decisions can enhance reliability and operational efficiency.

| Criteria | Description | Considerations |

|---|---|---|

| Type of Valve | Includes directional control valves, pressure control valves, and flow control valves. | Determine the specific needs of the lifting application. |

| Pressure Rating | Maximum pressure the valve can safely handle, usually measured in PSI. | Match the valve's pressure rating to the lifting platform's requirements. |

| Size and Porting | Refers to the valve size and the number of ports for hydraulic connections. | Ensure compatibility with existing hydraulic systems. |

| Material | Manufactured from steel, aluminum, or composite materials. | Consider environmental factors that may affect material choice. |

| Response Time | Time taken for the valve to respond to commands. | Evaluate the operational speed required for the lifting platform. |

| Cost | The purchase price of the valve. | Balance cost against quality and performance needs. |

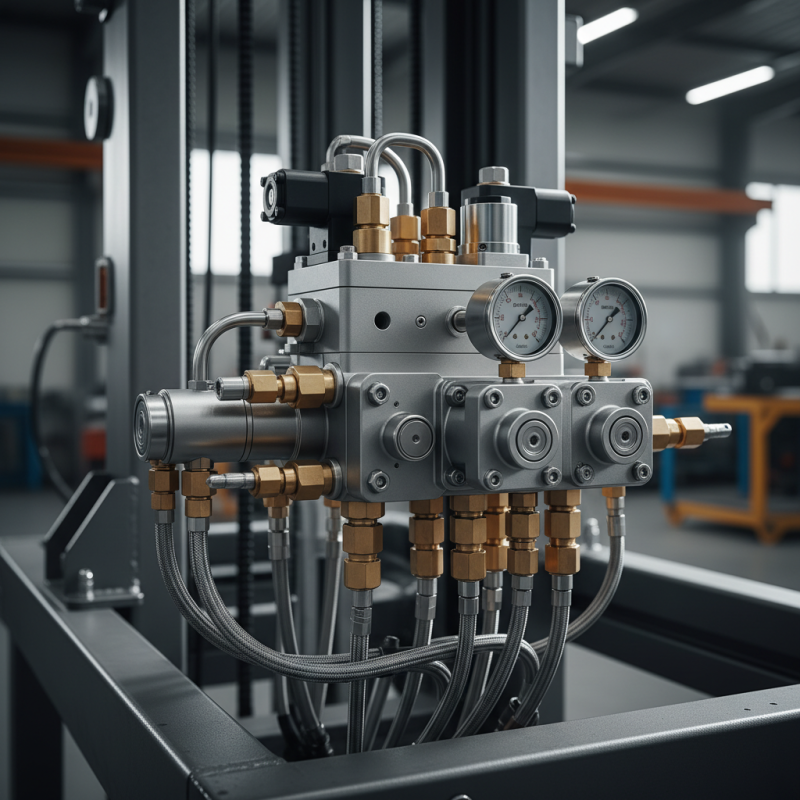

Choosing the right hydraulic valve for a lifting platform involves understanding key specifications. These include flow rate, pressure rating, and valve type. Flow rate is crucial. It affects how quickly the platform lifts. If the flow rate is too low, the lift will be sluggish. That can lead to operational issues.

Pressure rating is another vital factor. It indicates how much pressure the valve can handle. If mismatched, it could cause failure. A valve that can't withstand the required pressure will not last. The type of valve also matters. Different applications may require directional or flow control valves. Consider the specific needs of your lifting platform.

Pay attention to material compatibility as well. Some valve materials may not suit certain environments. This can lead to corrosion or failure over time. It’s often overlooked, but it’s important to reflect on the conditions your valve will face. Choosing the right valve is not just about specifications; it's about assessing your unique needs. Misjudgments here can lead to costly mistakes later.

This chart compares key specifications for different types of hydraulic valves commonly used in lifting platforms. It includes parameters such as Flow Rate (L/min), Maximum Pressure (Bar), and Response Time (ms).

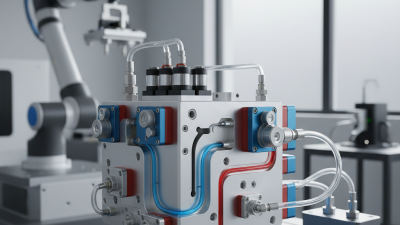

Choosing the right hydraulic valve for a lifting platform requires careful consideration. Compatibility is key. The valve must match the specifications of your platform design. Start by assessing the pressure and flow requirements. These factors dictate valve performance and efficiency.

Next, consider the type of hydraulic fluid in use. Different fluids can affect valve materials. For example, certain plastics may degrade over time. This can lead to failures. It's important to choose a valve that will withstand these conditions. Evaluate the temperature ranges as well. Extreme conditions might push standard components beyond their limits.

Finally, think about the mounting options. Some designs require specific orientations. If a valve doesn't fit properly, it can cause alignment issues. A poorly positioned valve may lead to leaks and performance loss. Always review installation instructions closely. Ensure everything aligns with your design requirements. Compatibility isn't just a technical aspect; it affects safety and efficiency as well.

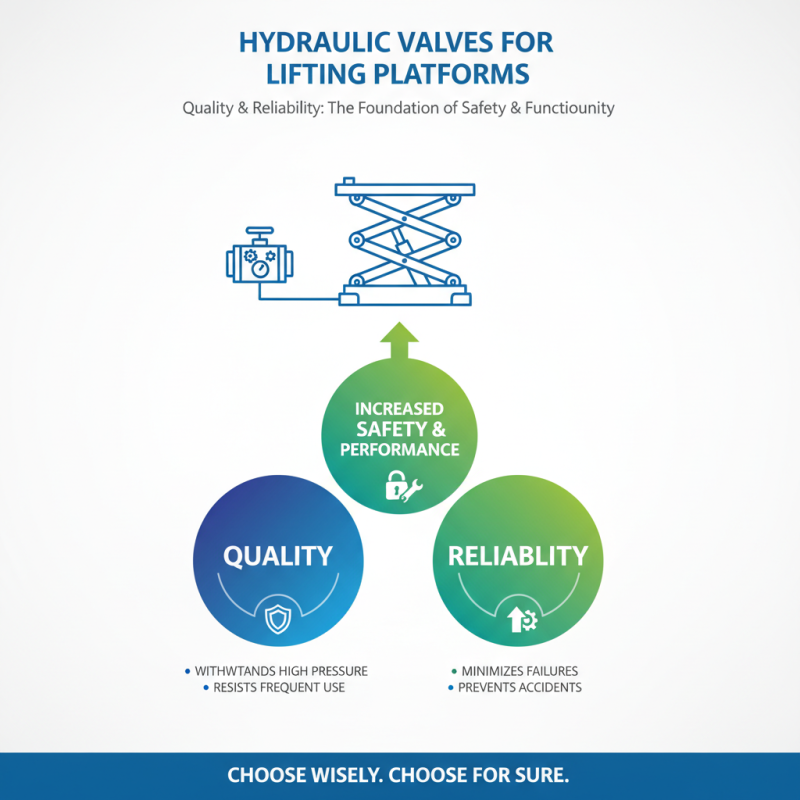

When selecting a hydraulic valve for a lifting platform, quality and reliability are crucial. These factors influence safety and functionality. High-quality valves can withstand high pressures and frequent use. A reliable valve minimizes the risk of failures that could lead to accidents.

Tips: Look for user reviews and expert opinions. Check the construction materials. Durable materials like steel or brass often ensure longevity. Additionally, consider certification standards. Valves that meet industry standards are typically more trustworthy.

Not all hydraulic valve brands offer the same quality. Some may focus on aesthetics rather than functionality. It's essential to evaluate real-life performance reports. Sometimes what looks good on paper might not work well in practice. Ask about warranty options. A longer warranty can indicate a manufacturer’s confidence in their product quality. Taking time to research will aid in making a sound decision.

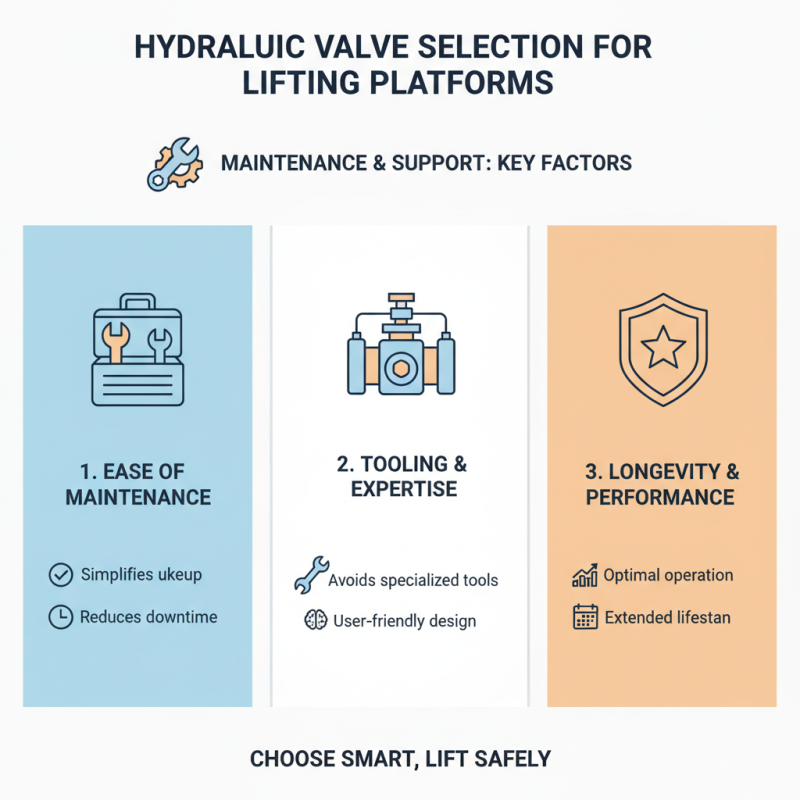

When selecting a hydraulic valve for a lifting platform, maintenance and support are key factors. It's important to consider how easy it is to maintain the valve. Regular maintenance ensures optimal performance and longevity. Some valves might require specialized tools for maintenance. This could complicate the process and increase downtime. Choosing a valve that is user-friendly can save time and effort.

Support options are also crucial. Effective customer service can be invaluable. When issues arise, quick and helpful support can minimize disruptions. Some manufacturers provide extensive documentation and online resources. Others may offer training for your team. Think about your specific needs when evaluating support. A vendor with a strong support system can make a difference.

Reflect on the future as well. Will the lifting platform require upgrades? Some hydraulic valves are versatile and adaptable. Others may become obsolete and hard to upgrade. Balance your current needs with potential future changes. This ensures you choose a valve that won't just work today, but will continue to support your operations in the long run.