Leave Your Message

In the rapidly evolving landscape of hydraulic systems, the importance of selecting the right Directional Control Valves cannot be overstated. As industries increasingly rely on precise fluid control mechanisms, understanding the various types and functionalities of these valves has become essential. According to a recent report by MarketsandMarkets, the global directional control valves market is projected to reach $7.2 billion by 2026, growing at a compound annual growth rate of 6.5%. This surge underscores the critical need for industry professionals to make informed decisions to meet operational demands effectively.

Experts in the field emphasize the significance of matching directional control valves to specific applications to enhance efficiency and performance. Dr. Emily Chen, a renowned hydraulic systems engineer, states, "Choosing the right Directional Control Valves is paramount; it directly impacts the overall efficiency and reliability of hydraulic systems.” This insight highlights the need for a comprehensive understanding of the various configurations, pressure ratings, and actuator types available in the market.

As we delve deeper into the nuances of selecting the appropriate valves for diverse applications, this guide aims to illuminate the key factors to consider, ensuring that industry stakeholders can make sound decisions that lead to optimized system performance and longevity.

Directional control valves are crucial components in hydraulic and pneumatic systems, serving to direct the flow of fluid within machinery. Understanding the different types and functions of these valves is essential to selecting the right one for your specific needs. The primary types of directional control valves include spool valves, poppet valves, and disc valves, each offering distinct advantages depending on the application. For instance, spool valves are commonly used when multiple flow paths are required, while poppet valves are ideal for applications that demand quick response times.

In addition to understanding the types, it's equally important to grasp their functional principles. Directional control valves operate by controlling the path of fluid flow, enabling or blocking passage based on the valve's position. This functionality is akin to how the heart manages blood flow throughout the body, directing it where it's needed most effectively. Just as your heart pumps blood through a network of arteries and veins, a well-chosen directional control valve ensures the efficient functioning of hydraulic or pneumatic systems, optimizing performance and enhancing reliability in various industrial applications.

When selecting directional control valves, key specifications play a crucial role in ensuring the right fit for your application. One of the primary factors to consider is the valve type, which can range from poppet valves to spool valves, each offering distinct advantages depending on the system requirements. For instance, spool valves are often preferred for their versatility and ability to control fluid flow in multiple pathways, making them ideal for complex systems.

Another critical specification is the flow rate and pressure rating of the valve. Ensuring that the chosen valve can handle the system's maximum flow rate and pressure is essential for optimal performance and longevity. Additionally, it's important to consider the valve's response time and actuation method—either manual, pneumatic, or electric—as these factors will impact how quickly and efficiently the valve can operate under varying conditions. Taking the time to evaluate these specifications will lead to better reliability and effectiveness in hydraulic or pneumatic applications.

When selecting the right directional control valves for specific applications, it is essential to analyze critical requirements such as size, flow rate, and operating pressure. The size of the valve must align with the piping dimensions and installation space, ensuring that it can fit comfortably and function effectively within the existing system. An appropriately sized valve not only enhances operational efficiency but also minimizes potential issues related to pressure drops and flow restrictions.

Understanding the required flow rate is another pivotal factor in the valve selection process. The flow rate directly influences the valve's capability to manage the necessary fluid dynamics, which is crucial for maintaining optimal system performance.

Finally, operating pressure must be taken into account, as it determines the durability and reliability of the valve under varying conditions. A valve that can withstand the operating pressure without compromising its integrity is vital for ensuring a safe and effective operation within the hydraulic or pneumatic systems.

When selecting directional control valves, one of the key factors to consider is the actuation method. The three primary options—manual, electric, and hydraulic—each have distinct advantages and applications that can significantly influence your decision.

Manual valves are often favored for their simplicity and reliability in low-demand applications. They require no external power source, making them ideal for situations where control is infrequent or remote location access is limited.

Electric actuation, on the other hand, offers greater precision and can facilitate automation in complex systems. These valves can be easily integrated into control systems, providing quick response times and reducing the need for manual intervention. This option is particularly beneficial in scenarios where real-time adjustments are necessary, such as in automated manufacturing processes.

Hydraulic actuation boasts high force capabilities and is suited for heavy-duty applications. These valves operate with fluid power, allowing for robust performance in demanding environments. It's important to evaluate the specific needs of your operation—consider factors like load requirements, response time, and automation needs when choosing the right actuation method.

Tips:

- Always evaluate the operating environment: temperature, pressure, and potential exposure to contaminants can influence valve performance.

- Consider future scalability: choose an actuation method that can easily be integrated into expanded systems if necessary.

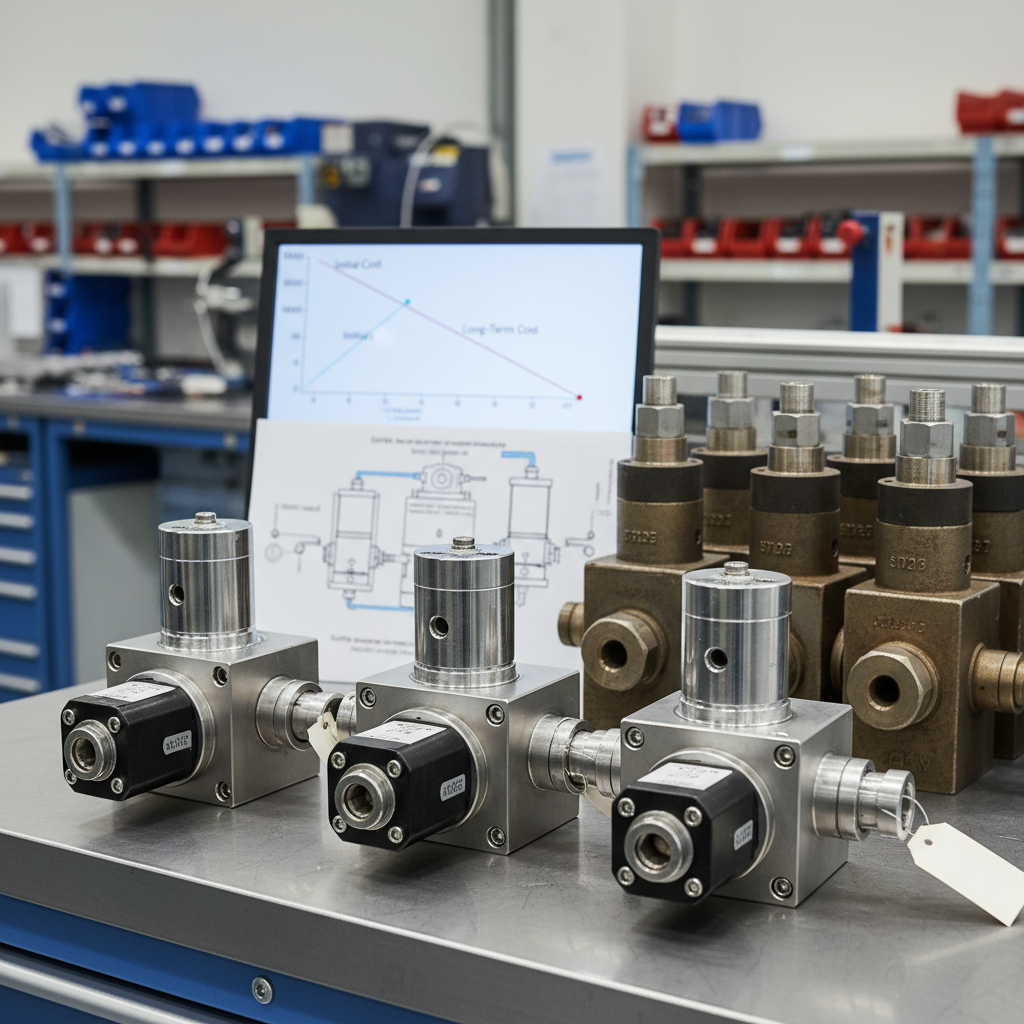

When selecting directional control valves, one of the critical factors to consider is the balance between cost efficiency and longevity. High-quality valves may require a higher initial investment, but they often provide better performance and durability over time. This long-term perspective is essential for industries that rely on hydraulic systems, where valve failure can lead to costly downtimes and repairs.

Investing in quality components minimizes maintenance needs and enhances the overall efficiency of the system.

Moreover, cost efficiency is not solely about the upfront price; it encompasses the total cost of ownership throughout the valve’s lifecycle. This includes factors like maintenance frequency, energy consumption, and longevity. Companies should evaluate the operational demands of their systems and select valves that can withstand the specific conditions they will face, ultimately leading to reduced operational costs. By prioritizing both quality and investment wisely, businesses can achieve a sustainable and effective solution that meets their directional control needs.