Leave Your Message

In modern industrial systems, effective pressure control is paramount to ensure efficiency, safety, and longevity. One critical component in achieving optimal pressure management is the Bidirectional Relief Valve. According to a recent report by the Global Pressure Control Market Insights, the demand for advanced pressure control technologies, including Bidirectional Relief Valves, is projected to grow at a CAGR of 5.6% from 2023 to 2030. This surge underscores the necessity for industry professionals to comprehend the role of such valves in maintaining system integrity.

Expert John Smith, a leading figure in fluid dynamics technology, emphasizes the importance of incorporating a Bidirectional Relief Valve in pressure-sensitive systems: "Without a properly functioning Bidirectional Relief Valve, systems are at risk of failing under pressure fluctuations, which can lead to catastrophic results." His insights resonate with engineers and operators who prioritize not only compliance with safety standards but also operational reliability. In this context, understanding the mechanics and benefits of Bidirectional Relief Valves becomes crucial for anyone involved in system design and management.

Effective pressure control is crucial for the optimal functioning of fluid systems across various industries. With improper pressure management, systems may experience inefficiencies, leading to equipment failure and increased operational costs. According to a report by the International Journal of Fluid Power, systems that utilize robust pressure control mechanisms can improve energy efficiency by up to 30%. A bidirectional relief valve plays a significant role here, providing precise pressure regulation by allowing fluid flow in both directions, thus ensuring that fluctuations in pressure are effectively managed.

In sectors such as manufacturing and petrochemicals, maintaining accurate pressure levels can directly influence production rates and safety standards. The American Society of Mechanical Engineers (ASME) emphasizes that nearly 40% of industrial accidents are related to equipment failure caused by inadequate pressure control. Implementing bidirectional relief valves not only enhances operational efficiency but also protects against potential hazards and financial losses. By ensuring consistent pressure conditions, businesses can maintain productivity while minimizing risks associated with pressure extremes.

Bidirectional relief valves play a crucial role in maintaining optimal pressure control within various systems. Understanding the mechanisms behind these valves can help us appreciate their effectiveness. A bidirectional relief valve functions by allowing fluid to flow in both directions, which enables it to respond dynamically to pressure fluctuations. This design prevents excessive pressure build-up and maintains stability by automatically adjusting to changes in the system's demands.

Bidirectional relief valves play a crucial role in maintaining optimal pressure control within various systems. Understanding the mechanisms behind these valves can help us appreciate their effectiveness. A bidirectional relief valve functions by allowing fluid to flow in both directions, which enables it to respond dynamically to pressure fluctuations. This design prevents excessive pressure build-up and maintains stability by automatically adjusting to changes in the system's demands.

Drawing a parallel with advances in medical technology, the concept of bidirectional modulation resonates with recent findings in spinal cord stimulation (SCS) therapies. These therapies utilize integrated spinal and supraspinal mechanisms to address chronic pain, similar to how a bidirectional relief valve manages pressure. By modulating neuroplasticity, the SCS method effectively alters pain pathways, providing relief to patients. This noninvasive approach exemplifies the importance of understanding mechanisms in both mechanical and biological systems, where coordinated responses ensure optimal functionality and patient outcomes, emphasizing the need for precision in design and implementation in various fields.

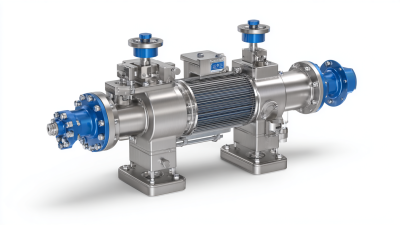

Bidirectional relief valves are essential components in various hydraulic and pneumatic systems, offering distinct advantages that can greatly enhance operational efficiency and safety. One of the key benefits is their ability to maintain optimal pressure control in both directions of flow. According to a report by the International Fluid Power Society, systems utilizing bidirectional relief valves can reduce pressure fluctuations by up to 40%, which minimizes the risk of component failure and system downtime.

Additionally, bidirectional relief valves contribute significantly to energy savings. A study conducted by the Hydraulic Institute indicates that systems equipped with these valves can achieve energy efficiency improvements of 15-25%. By preventing excessive pressure buildup and allowing for precise pressure management, these valves ensure that hydraulic pumps and motors operate within their optimal ranges. This not only extends the lifespan of the equipment but also reduces energy consumption, leading to lower operational costs.

Moreover, the adaptability of bidirectional relief valves allows for easier integration into existing systems. Their compact design and versatile application make them suitable for various industries, from manufacturing to automotive. This capability enables businesses to enhance their system performance without extensive modifications, ultimately promoting sustainability and competitive advantage in the marketplace. Implementing bidirectional relief valves is a strategic move towards achieving a more efficient and reliable operational framework.

Bidirectional relief valves play a crucial role in various industrial applications by providing effective pressure control and maintaining system stability. These valves allow fluid to flow in both directions while ensuring that excessive pressure is safely released, which is essential in preventing equipment damage and enhancing operational safety. Their versatility makes them suitable for a range of applications, particularly in high-flow environments such as chemical processing, municipal water treatment, and oil and gas distribution.

In the context of recent technological advancements, the introduction of new valve products, including those specifically designed for high-flow applications and municipal water systems, underscores the importance of integrating bidirectional relief valves into modern systems. These innovations not only enhance safety but also simplify installation processes, making them ideal for environments that demand reliable performance under variable flow conditions. By incorporating such valves, industries can achieve better pressure management while ensuring compliance with safety standards and operational efficiency.

| Application | Industry | Pressure Rating (psi) | Material | Key Benefits |

|---|---|---|---|---|

| Hydraulic Systems | Manufacturing | 3000 | Steel | Improved safety, reduced downtime |

| Lubrication Systems | Automotive | 2500 | Aluminum | Energy efficient, consistent performance |

| Water Treatment | Environmental | 1500 | Plastic | Corrosion resistant, lightweight |

| Oil Pipeline | Oil & Gas | 5000 | Carbon Steel | Pressure stability, leak prevention |

| Chemical Processing | Chemical | 2000 | Stainless Steel | Versatile, high durability |

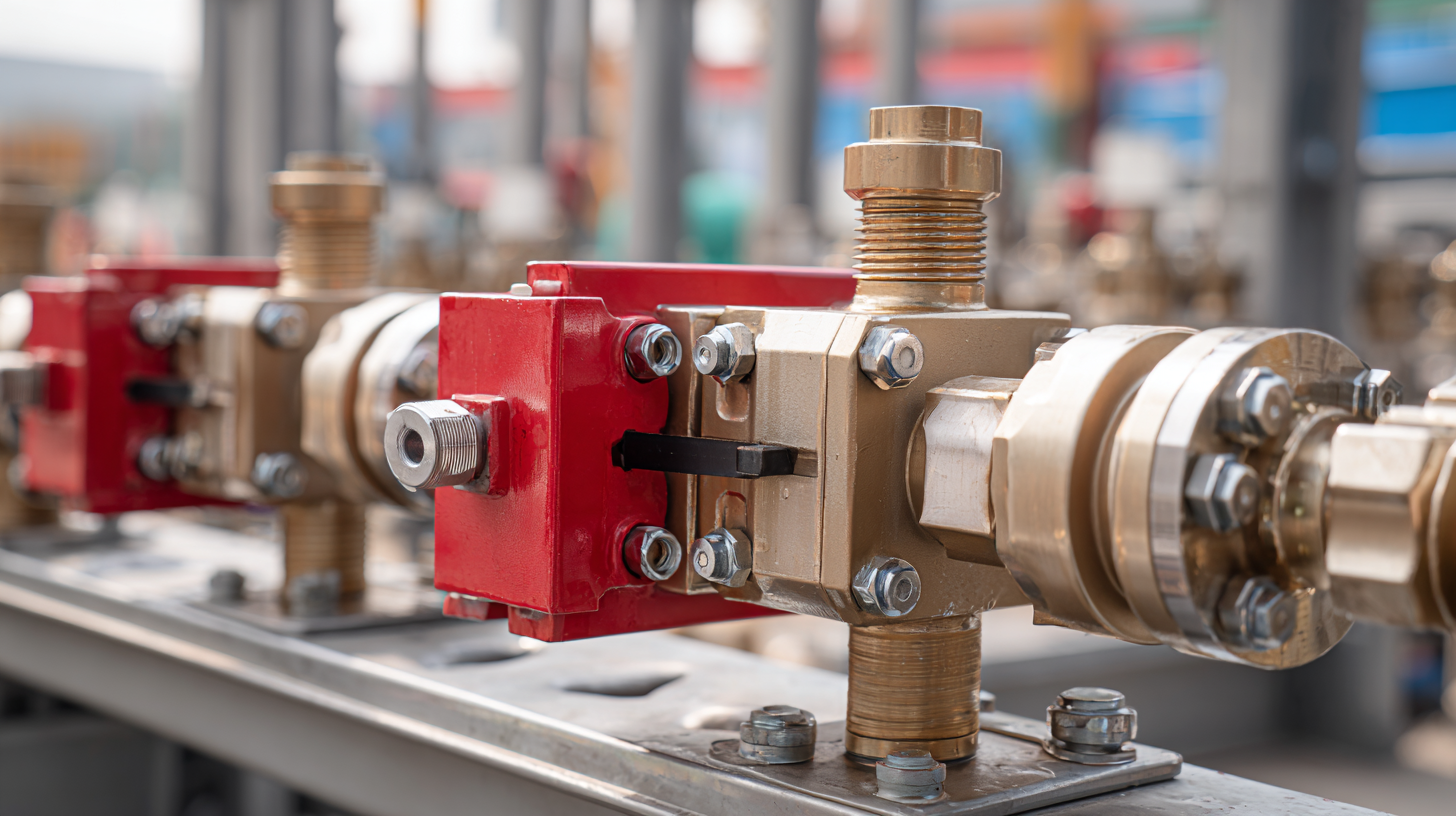

Maintaining optimal pressure control in fluid systems is crucial for ensuring operational efficiency and safety. A bidirectional relief valve plays a vital role in this maintenance by allowing fluid flows to be managed effectively in both directions. One best practice is regular inspection of the valve for any signs of wear or damage, as this can prevent malfunction during critical operations. Operators should also ensure proper installation, confirming that the valve is correctly oriented and accessible for servicing.

Additionally, routine testing of the system's pressure settings can help identify any inconsistencies before they lead to larger issues. Implementing a systematic maintenance schedule, including cleaning and lubricating components, will enhance the performance of the bidirectional relief valve. It’s equally important to be aware of the system's specific requirements and environmental factors that could affect its operation. By following these best practices, users can optimize the efficiency and reliability of their pressure control systems.

This chart illustrates the optimal pressure control achieved with a bidirectional relief valve compared to traditional pressure control methods. The data represents pressure readings (in PSI) over time (in hours).